Introduction[edit | edit source]

A lithium-ion battery or Li-ion battery is a rechargeable battery composed of cells. The lithium ions move from the negative electrode through an electrolyte to the positive electrode during discharge and back when charging.

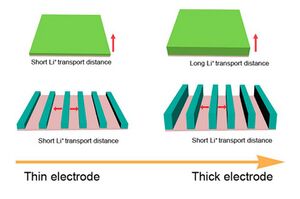

The performance of a Li-ion battery depends on the performance of electrodes. Although extensive research strategies have been put forward to develop high-performance Li-ion batteries, this area still has shortcomings, mainly because of the lack of appropriate electrodes for practical applications. In the research, the focus was on enhancing the energy density and the power density of anode electrodes. As already known, in thick anodes, the energy density is suitable and high enough because of the high percentage of Li-ions. But once the anode gets thicker, the power density decreases. The reason is that the high-power density is obtained when the transportation distance for Li-ions shortens (Figure 1).[1]

Purpose[edit | edit source]

The motivation for the research project was to target the issues mentioned above by 3D printing of anodes for Li-ion batteries. 3D printing, also known as additive manufacturing, creates a three-dimensional object layer-by-layer using a CAD. It is known that 3D-printing of anodes improves the performance by increasing the energy density by thickening the electrodes and increasing the power density by shortening the ions transportation distance. The novelty of the research was designing and 3D-printing the optimum geometry for the anodes which perform the highest energy and power densities.

Experiments[edit | edit source]

The project had five main phases. First of all, Available and sufficient materials were prepared (Lithium-titanate (LOT) / Graphene and Polylactic-acid (PLA)), and a component was created for the anode electrode. A filament was made using a screw extruder with the component.

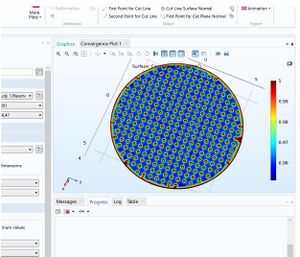

Then, Coin-shaped anodes, which had micrometer pores inside them, were designed using SolidWorks software (Figure 2).

After that, Using the Fused deposition modeling (FDM) printer, the designed anodes with the artificial filament were printed.

The next phase was obtaining Cyclic Voltammetry results from the experiment. The system was half-cell with Lithium coin as the cathode. The anode was attached on copper foil with PVDF+NMP paste. The electrolyte was LiPF6 (Lithium hexafluorophosphate) in EC/DMC (ethylene carbonate and dimethyl carbonate) 1:1 molar.

Finally, the whole experimental section was simulated using COMSOL software. Through this software, Li-ion battery physics was used, and Cyclic Voltammetry results for all the geometries and sizes of the designed electrodes were obtained. The mesh model was purposefully divided into tiny particles to perform the equation. The relevant equation for the single mesh particles was the diffusion equation – Fick’s Law (Figure 3).

Results[edit | edit source]

The results are listed as below:

1- The layer-by-layer concept of 3D printing helped increase the thickness of the anodes to improve the energy density.

2- The layers did not bind on the microscopic scale and made it easier for Li-ions to transport through the electrode to increase the power density.

3- Coin-shaped designed anodes with microscopic pores helped the power density remains high.

4- The optimized geometry for high energy and power density was achieved.

5- Comparing the experimental results with the simulated ones, we concluded that the simulation results were close to the experimental results, which showed the accuracy of experiments.