A wind turbine, wind energy harvester or wind energy conversion system is a machine that, powered by the energy of the wind, generates mechanical energy that is directly converted to electricity. The term wind energy harvester however can refer to windmills and windpumps as well as wind turbines.

Several types of wind energy harvesters exist, each type being better in a specific situation (ie lower or higher altitudes, variable wind speeds, ...)

VAWT wind energy harvesters[edit | edit source]

On lower altitudes above the soil, VAWT's (vertical axis wind turbines) are more efficient than HAWTs. Several types exist including Panemone, Savonius, Darrieus and Variable geometry HAWT's. Their efficiency can be read at following articles:

VAWT harvesters design is different from what people most associate with wind turbines. They are set up where the "main rotor shaft is set traverse to the wind while the main components are located at the base of the turbine.". This makes it so the generator and the gearbox are closer to the ground so that they are easier to maintain and operate.

Advantages:

- They don't need to track the wind so they don't require complex mechanisms.

- Take advantage of the wind better than HAWT's

- Replacement is cheaper than HAWT's/ Cranes and such are not required for the site because it is designed closer to the ground.

- They are shorter than HAWT's so they can be installed below the HAWT's turbines and they can be installed closer together

Disadvantages

- The blades can stall depending on the speed and angle of the wind.

- They are less reliable than HAWT

- The blades are fatigue prone

HAWT wind energy harvesters[edit | edit source]

On higher altitudes above the soil, HAWT's (horizontal axis wind turbines) are more efficient than VAWTs.

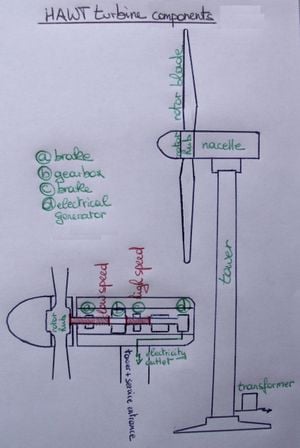

A basic HAWT wind harvester is composed of the following components:[1]

- tower

- bladed rotor

- mechanical-electricity generator (eg dynamo or alternator)

- transformer (and inverter; if needed)

A regular HAWT wind turbine comes with a tower at least 30 feet above obstructions. To power a regular family house a 30 metre high tower is even recommended with blades spanning 5 meters in diameter (see Domestic energy consumption). There are two basic types of towers useful for residential wind power systems (free standing and guyed). Free standing towers are self supporting and are usually heavier which means they take special equipment (cranes) to place them. Guyed towers are supported on a concrete base and anchored by wires for support. They typically are not as heavy and most manufacturer's produce tilt down models which may be easily raised and lowered for maintenance.

The kinetic (moving energy) from the winds is harnessed by a device known as the turbine. This turbine contains airfoils (blades) that capture the energy of the wind and use it to turn the shaft of an alternator (like you have on a car only bigger).

There are 2 basic kinds of blades (drag style and lifting style). We all have seen pictures of groundsailor windmills and these are a good example of the drag style of airfoil. Lifting style blades are twisted instead of flat and resemble the propellor of a small airplane.

A HAWT turbine is classified as to whether the wind strikes the blades or the tower first. A vertical turbine typically requires less land for it's installation and is a better option for the more urban areas on the planet. An upwind turbine is created for the wind to impact the airfoils before it does the tower.

These units normally have a tail on the turbine which is required to maintain the unit pointed into the wind. A downwind turbine doesn't need a tail as the wind acting on the blades tends to keep it oriented properly.

These turbine systems would be damaged if they were to be allowed to turn at excessive speeds. Therefore, units should have automatic over-speed governing systems. Some systems use electrical braking systems although some use mechanical type brakes.

The output electricity from the alternator is sent to a controller which conditions it for use in the home. The usage of residential wind power systems requires the home to either remain linked with the utility grid or store electricity in a battery for use when the wind doesn't blow sufficiently.

When the home is tied to the grid, the excess electricity that is created by the residential wind power system can be sold to the utility company to reduce and sometimes even eliminate your electric bill. During times with not enough wind, the home is supplied power from the utility company.

Cost effective towers are ie the tower design used by Seeba (used ie in Nike's wind turbines at Laakdak, see http://en.wikipedia.org/wiki/Nike_Laakdal_Wind_Park )

Also note that unconventional HAWT wind turbine designs also exist. Some designs (such as the bladeless wind turbine) may be even much more efficient, yet may be more difficult and more expensive to make.

Obtaining optimal efficiency[edit | edit source]

Regardless of the type of wind turbine used, the optimal power output is not obtained in practice at wind speeds above or below what the wind turbine was designed for. This is due to the alternator or dynamo used, which tends to be chosen for a specific wind speed. If the wind speed goes above or below this speed, the efficiency is much lower than what could actually be harvested at this time.

Solutions to these problems are:

- a gearbox

- a furling system; these include variable pitch blades, tail furling, tilt-back furling, blade flexing

Gearboxes are the most efficient solution since they allow the turbine to use all available wind energy. However, the downside (and the reason why gearboxes are almost never used, especially not with small-scale wind turbines -they tend to make use of gear reducers or gear increasers instead-) is that they tend to make the wind turbine complex and expensive. This, as a PCB connected to a wind speed meter needs to be present to measure the wind speed, and then change the gears accordingly, so that the alternator may keep rotating at its optimal RPM.

Furling systems do things differently; rather than taking advantage of all wind energy, they just make the turbine blades capture less wind energy, so that the rotor remains rotating at a same RPM. Variable pitch blades do this by changing the angle of attack of the airfoils (blades); tail furling rotate the wind turbine's head away horizontally; tilt-back furling does the same but than in the vertical direction, and blade flexing twists the blades.

Another problem with wind turbines is that, when the site has been poorly chosen, and turbulence (non-laminar air flow) is present (due to obstacles as trees, houses, ... in the vicinity), the turbine's head tends to rotate left to right and vice versa and this constantly. the result is that very little of the wind power can actually be captured by the blades. The best solution is to just pick your site carefully (so that it's turbulence-free). Alternatively, a system that has solenoid-activated pins (which are mostly activated, yet deactivate every 10 minutes or so to allow the head to reposition itself as the wind has turned by many degrees) may prove to be a solution.

External links[edit | edit source]

- Wikipedia:Wind turbine

- For DIY wind turbine designs, see here

- http://web.archive.org/web/20160602153822/http://peswiki.com/energy/Directory:Wind

- http://www.residentialwindturbines.org/wind-scheme-grid-tied.gif