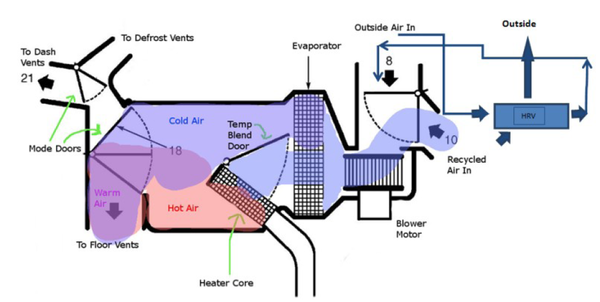

Vehicles could save ~110 million gallons of gasoline per year in the U.S. with heat exchangers acting as heat recovery ventilators in the air conditioning systems. Even more energy could be saved with in-vehicle heat exchangers by reducing heating energy in plug-in vehicles. Currently, vehicles do not have heat recovery ventilators because of the high cost of conventional metal heat exchangers. To overcome this challenge, low-cost expanded polymer microchannel heat exchangers were studied. Forward conduction laser welding was used to join 25-micron thick linear low-density polyethylene sheets, which were then fixed into shape and expanded. The microchannel polymer heat exchangers were tested at various air flow rates. At the maximum flow rate, the effectiveness was ~70% and the implications of this expanded heat exchanger in other applications are discussed.

Replicate these results with laser welding system[edit | edit source]

- Experimental Characterization of Heat Transfer in an Additively Manufactured Polymer Heat Exchanger

- Expanded microchannel heat exchanger

- Open-source laser system for polymeric welding - open source hardware design

- Laser welding protocol: MOST - operating instructions

- Open Source Laser Polymer Welding System: Design and Characterization of Linear Low-Density Polyethylene Multilayer Welds

- Expanded Microchannel Heat Exchanger: Finite Difference Modeling

See also[edit | edit source]

- Expanded microchannel heat exchanger

- Open source laser system for polymeric welding

- Laser welding protocol: MOST

- Open Source Multi-Head 3D Printer for Polymer-Metal Composite Component Manufacturing

- Design Optimization of Polymer Heat Exchanger for Automated Household-Scale Solar Water Pasteurizer

- Expanded microchannel heat exchanger: Non-destructive evaluation

- Finite Difference Heat Exchanger Model: Flow Maldistribution with Thermal Coupling

- Expanded Microchannel Heat Exchanger: Finite Difference Modeling

In the news[edit | edit source]

- Better Heat Exchangers Using Garbage Bags - Science Daily, Locker Dome

- Garbage bags could make power plants more efficient - Mumbai Mirror (a daily circulation of approximate 700,000).