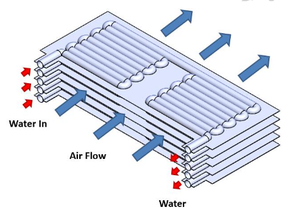

In addition to their low cost and weight, polymer heat exchangers offer good anticorrosion and antifouling properties. In this work, a cost effective air-water polymer heat exchanger made of thin polymer sheets using layer-by-layer line welding with a laser through an additive manufacturing process was fabricated and experimentally tested. The flow channels were made of 150 μm-thick high density polyethylene sheets, which were 15.5 cm wide and 29 cm long. The experimental results show that the overall heat transfer coefficient of 35-120 W/m2K is achievable for an air-water fluid combination for air-side flow rate of 3-24 L/s and water-side flow rate of 12.5 mL/s. In addition, by fabricating a very thin wall heat exchanger (150 μm), the wall thermal resistance, which usually becomes the limiting factor on polymer heat exchangers, was calculated to account for only 3% of the total thermal resistance. A comparison of the air-side heat transfer coefficient of the present polymer heat exchanger with some of the commercially available plain plate fin heat exchanger surfaces suggests that its performance in general is superior to that of common plain plate fin surfaces.

Highlights[edit | edit source]

- HDPE polymer HX is fabricated using layer-by-layer line welding of plastic sheets.

- Experimental testing of the HX has been successfully performed.

- The polymer-based wall thermal resistance is no longer the limiting factor.

- The polymer HX shows superior air-side performance over plane plate fin surface.

Replicate these results with laser welding system[edit | edit source]

- Repository contains the python code used to generate all the.gcode, the SCAD files for the open source polymer welder

- Laser welding protocol: MOST - operating instructions

- Open-source laser system for polymeric welding - more on the open source hardware design

See also[edit | edit source]

- Open Source Laser Polymer Welding System: Design and Characterization of Linear Low-Density Polyethylene Multilayer Welds

- Expanded microchannel heat exchanger

- Towards Low-Cost Microchannel Heat Exchangers: Vehicle Heat Recovery Ventilator Prototype

- Open source laser system for polymeric welding

- Laser welding protocol: MOST

- Open Source Polymer Welder Literature Review

- Open Source Multi-Head 3D Printer for Polymer-Metal Composite Component Manufacturing

- Design Optimization of Polymer Heat Exchanger for Automated Household-Scale Solar Water Pasteurizer

- Expanded microchannel heat exchanger: Non-destructive evaluation

- Expanded Microchannel Heat Exchanger: Finite Difference Modeling