Understanding the market

A non-trivial cost of building a 3D printer is buying the hotend. In some parts of the world, the cost of importing hotends is prohibitive. Without considering the cost of shipping to remote areas of the world, a low-end hotend described as the "most affordable 3D printer hotend yet" retails for almost $32[1]. A hotend cast from silicone and nichrome wire in a printed PLA mold would significantly increase the availability of hotends in remote areas.

Project goals

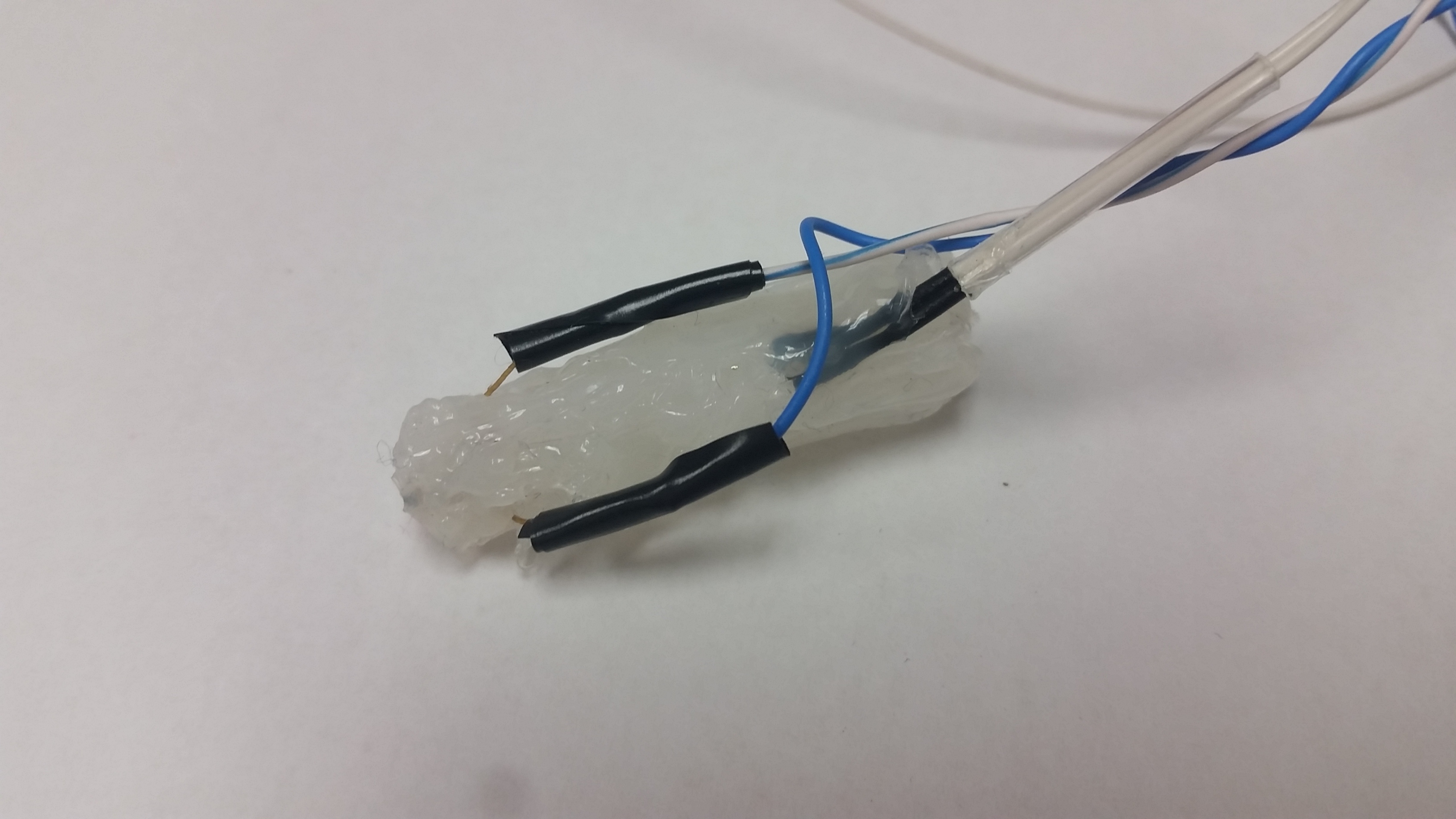

This project seeks to design a 3D printed mold in PLA to cast a silicone based hot end, into which a nichrome wire can be inserted as a heating element.

Considerations include:

- Design of mold

- Choice of silicone

- Design of casting process

- Inserting silicone

- Nichrome wire placement

- Channel for filament

Design

The male and female molds were designed in FreeCAD to replicate an existing hot end design. The first iteration of hot ends were cast, but ultimately failed due to very long cure times and large trapped air bubbled. The improved method of producing the silicone body involves painting thin layers of silicone and letting it cure between each layer. While a more work intensive process, it leads to a much shorter cure time because the product is exposed to air.

Parts

- Silicone

- Printed male and female mold

- Male

- Female

- Nichrome wire

- Thermistor

Tools

- Soldering gun and solder

- Pin

- 0.5mm pencil lead

- Electrical tape

Method

- Obtain printed parts (