No edit summary |

m (Removed extra teturns.) |

||

| Line 1: | Line 1: | ||

{{115inprogress|December 22, 2009}} | {{115inprogress|December 22, 2009}} | ||

[[Image:Leons 001.jpg|thumb|left|425px|Figure 1. General Manager Dale Warmuth]] | [[Image:Leons 001.jpg|thumb|left|425px|Figure 1. General Manager Dale Warmuth]] | ||

== | ==Energy Efficiency Retrofit For Leon's Car Care Center== | ||

Lighting accounts for 20% to 50% of the energy consumed by a commercial building.<ref> | Lighting accounts for 20% to 50% of the energy consumed by a commercial building.<ref> | ||

http://en.wikipedia.org/wiki/Lighting#Energy_consumption | http://en.wikipedia.org/wiki/Lighting#Energy_consumption | ||

</ref> In June 2008 the [http://www.redwoodenergy.org Redwood Coast Energy Authority] (RCEA) completed the first phase of a lighting retrofit for [http://www.leonsmufflers.com Leon's Car Care Center] with the replacement of 40 fluorescent light fixtures. The second phase saw the installation of an energy miser to reduce electrical consumption of the vending machines in the office. Leons completed the final phase of the retrofit independent of the RCEA with the replacement of 32 metal halide light fixtures in the shop area. | </ref> In June 2008 the [http://www.redwoodenergy.org Redwood Coast Energy Authority] (RCEA) completed the first phase of a lighting retrofit for [http://www.leonsmufflers.com Leon's Car Care Center] with the replacement of 40 fluorescent light fixtures. The second phase saw the installation of an energy miser to reduce electrical consumption of the vending machines in the office. Leons completed the final phase of the retrofit independent of the RCEA with the replacement of 32 metal halide light fixtures in the shop area. | ||

=== Building History === | === Building History === | ||

Leon's Car Care Center (Figure 1) is a family owned and operated business that has been in [http://maps.google.com/maps?q=Eureka+CA&oe=utf-8&rls=org.mozilla:en-US:official&client=firefox-a&um=1&ie=UTF-8&hq=&hnear=Eureka,+CA&gl=us&ei=KxgbS8DDDc7ZnAf9xaTRAw&sa=X&oi=geocode_result&ct=title&resnum=1&ved=0CAoQ8gEwAA Eureka, California] for over 48 years. Since 1992 Leon's Car Care Center has been located in a steel I-beam shop structure with an attached wood frame office, built new to their specifications. The building was designed to utilize windows built into the upper reaches of the structure allowing natural light to penetrate to the main shop area and decrease the reliance on electric light. | Leon's Car Care Center (Figure 1) is a family owned and operated business that has been in [http://maps.google.com/maps?q=Eureka+CA&oe=utf-8&rls=org.mozilla:en-US:official&client=firefox-a&um=1&ie=UTF-8&hq=&hnear=Eureka,+CA&gl=us&ei=KxgbS8DDDc7ZnAf9xaTRAw&sa=X&oi=geocode_result&ct=title&resnum=1&ved=0CAoQ8gEwAA Eureka, California] for over 48 years. Since 1992 Leon's Car Care Center has been located in a steel I-beam shop structure with an attached wood frame office, built new to their specifications. The building was designed to utilize windows built into the upper reaches of the structure allowing natural light to penetrate to the main shop area and decrease the reliance on electric light. | ||

=== Electrical Demand === | === Electrical Demand === | ||

Automotive repair requires the use of power tools and computerized diagnostic equipment in addition. The tools use more energy to operate, but are used sporadically, whereas lights are on continuously. The shop is equipped with 8 vehicle lifts, two air compressors, and computers for diagnostic repair. These lights were supplemented with wall mounted fluorescent lights for work bench and lower applications. The office is illuminated with fluorescent lights, contains computers, two climate control units, one cold soft drink vending machine and a snack vending machine. | |||

Automotive repair requires the use of power tools and computerized diagnostic equipment in addition. The tools use more energy to operate, but are used sporadically, whereas lights are on continuously. The shop is equipped with 8 vehicle lifts, two air compressors, and computers for diagnostic repair. These lights were supplemented with wall mounted fluorescent lights for work bench and lower applications. The office is illuminated with fluorescent lights, contains computers, two climate control units, one cold soft drink vending machine and a snack vending machine. | |||

=== Redwood Coast Energy Authority (RCEA) === | === Redwood Coast Energy Authority (RCEA) === | ||

| Line 20: | Line 18: | ||

</ref> The organization is funded through taxes collected by PG&E and the CPUC. The RCEA also operates under a smaller contract with the US [http://www.energy.gov/ Department of Energy] (DOE) to promote solar energy use.<ref> | </ref> The organization is funded through taxes collected by PG&E and the CPUC. The RCEA also operates under a smaller contract with the US [http://www.energy.gov/ Department of Energy] (DOE) to promote solar energy use.<ref> | ||

http://www.energy.gov/energysources/solar.htm | http://www.energy.gov/energysources/solar.htm | ||

</ref | </ref> | ||

==== Redwood Coast Energy Watch (RCEW)==== | ==== Redwood Coast Energy Watch (RCEW)==== | ||

The [http://www.redwoodenergy.org/ContentPage.asp?ContentID=392 Redwood Coast Energy Watch] (RCEW) is a $1.6 million partnership program between the RCEA and the [http://www.pge.com/about/ Pacific Gas and Electric] company (PG&E) responsible for the project. Funded by the [http://www.cpuc.ca.gov/puc California Public Utilities Commission] (CPUC) [http://www.cpuc.ca.gov/cfaqs/publicgoodschargepgc.htm public goods charge], the RCEW is responsible for the energy efficiency upgrades at Leons Car Care Center and other area businesses. | |||

==Retrofit Hardware== | |||

= | |||

====Fluorescent Lighting==== | ====Fluorescent Lighting==== | ||

| Line 37: | Line 34: | ||

http://www.aboutlightingcontrols.org/education/papers/2008_nemaballasts.shtml</ref> Older magnetic ballasted fixtures have a noticeable [http://en.wikipedia.org/wiki/Fluorescent_lamp#Flicker_problems flicker] that can reduce efficiency of the lamp by up to ten percent.<ref> | http://www.aboutlightingcontrols.org/education/papers/2008_nemaballasts.shtml</ref> Older magnetic ballasted fixtures have a noticeable [http://en.wikipedia.org/wiki/Fluorescent_lamp#Flicker_problems flicker] that can reduce efficiency of the lamp by up to ten percent.<ref> | ||

http://en.wikipedia.org/wiki/Fluorescent_lamp#Ballast | http://en.wikipedia.org/wiki/Fluorescent_lamp#Ballast | ||

</ref | </ref> | ||

All of the existing two lamp fluorescent fixtures in the shop and office (Figure 2) were replaced by the RCEA during the first phase of the retrofit. 31 electronic and nine magnetic T12 ballasted fixtures have been replaced with T8 ballasted fixtures at this time. During the final phase of the retrofit Leons replaced 32 400 watt [http://en.wikipedia.org/wiki/Metal_halide_lamp High Intensity Discharge] (HID) metal halide lamps (Figure 3) with six lamp T8 ballasted fluorescent fixtures (Figure 4). Metal halide lamps can cost 50% more<ref> | All of the existing two lamp fluorescent fixtures in the shop and office (Figure 2) were replaced by the RCEA during the first phase of the retrofit. 31 electronic and nine magnetic T12 ballasted fixtures have been replaced with T8 ballasted fixtures at this time. During the final phase of the retrofit Leons replaced 32 400 watt [http://en.wikipedia.org/wiki/Metal_halide_lamp High Intensity Discharge] (HID) metal halide lamps (Figure 3) with six lamp T8 ballasted fluorescent fixtures (Figure 4). Metal halide lamps can cost 50% more<ref> | ||

| Line 54: | Line 51: | ||

====Energy Miser==== | ====Energy Miser==== | ||

The RCEA has overseen the installation of an energy miser (Figure 5) on the snack and cold drink vending machines in the office. The miser acts as a motion sensor in conjunction with a timer that shuts the appliances down after a period of inactivity. According to retailer [http://www.austinenergy.com Austin Energy,]the potential savings from an energy miser on a cold drink machine is 40% and 80% on a snack machine. | The RCEA has overseen the installation of an energy miser (Figure 5) on the snack and cold drink vending machines in the office. The miser acts as a motion sensor in conjunction with a timer that shuts the appliances down after a period of inactivity. According to retailer [http://www.austinenergy.com Austin Energy,]the potential savings from an energy miser on a cold drink machine is 40% and 80% on a snack machine. | ||

<br><br> | <br><br> | ||

== | ==Data Analysis== | ||

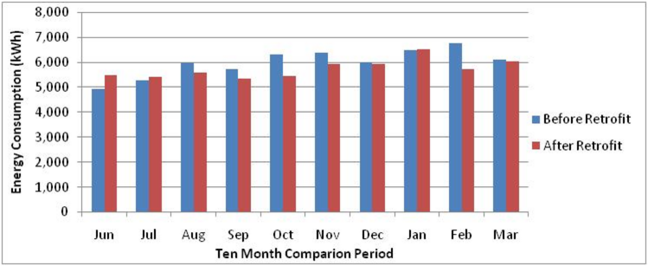

To determine whether or not the RCEA retrofits had reduced power consumption at Leons, electrical consumption was compared before and after the retrofit(Figure 6). The time period from June 2008 to March 2009 was selected to reflect power consumption changes as a result of the RCEA retrofit. The time period was limited to ten months because in April 2009 Leons replaced multiple metal halides with fluorescent lights. The time period from June 2007 to March 2008 was selected as a comparison period before the retrofit. Analysis of the data showed that after the retrofit, electrical consumption went down from the previous year.'''(should also compare the Leon retrofits at least graphically use different series for each time, don't use grey backgrounds in graphs.)''' | To determine whether or not the RCEA retrofits had reduced power consumption at Leons, electrical consumption was compared before and after the retrofit(Figure 6). The time period from June 2008 to March 2009 was selected to reflect power consumption changes as a result of the RCEA retrofit. The time period was limited to ten months because in April 2009 Leons replaced multiple metal halides with fluorescent lights. The time period from June 2007 to March 2008 was selected as a comparison period before the retrofit. Analysis of the data showed that after the retrofit, electrical consumption went down from the previous year.'''(should also compare the Leon retrofits at least graphically use different series for each time, don't use grey backgrounds in graphs.)''' | ||

<br> | <br> | ||

| Line 96: | Line 91: | ||

=== Predicted Versus Actual Savings === | === Predicted Versus Actual Savings === | ||

We compared the RCEA predicted savings with the savings we calculated using power consumption data. Since the RCEA made predicted savings based on a time period of one year, and our comparison was confined to a 10 month period starting in June 2008 running till March 2009, there was an adjustment that was necessary. To compare like quantities of time, total kWh from the 10 month period was divided by 10 to get a monthly kWh figure. The monthly kWh figure was then multiplied by 12 to give an estimated yearly kWh total. Below is a comparison of the predicted savings versus the savings shown after analyzing the data.'''(combine with CO2 Table, only have two columns, A1)'''<br> | We compared the RCEA predicted savings with the savings we calculated using power consumption data. Since the RCEA made predicted savings based on a time period of one year, and our comparison was confined to a 10 month period starting in June 2008 running till March 2009, there was an adjustment that was necessary. To compare like quantities of time, total kWh from the 10 month period was divided by 10 to get a monthly kWh figure. The monthly kWh figure was then multiplied by 12 to give an estimated yearly kWh total. Below is a comparison of the predicted savings versus the savings shown after analyzing the data.'''(combine with CO2 Table, only have two columns, A1)'''<br> | ||

| Line 119: | Line 113: | ||

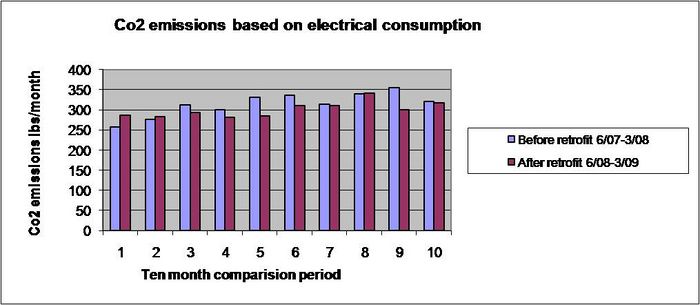

=== Carbon Dioxide (CO<sub>2</sub>) Emissions === | === Carbon Dioxide (CO<sub>2</sub>) Emissions === | ||

[[Image:Humco_elec_supply_chart.jpg|thumb|right|400px|Figure 7. Distribution of Energy Sources]] | [[Image:Humco_elec_supply_chart.jpg|thumb|right|400px|Figure 7. Distribution of Energy Sources]] | ||

CO<sub>2</sub> is the standard by which all other [http://en.wikipedia.org/wiki/Greenhouse_gas green house gases] (GHG) are measured. With a [http://en.wikipedia.org/wiki/Global_warming_potential global warming potential] (GWP) value of one, regardless of the time period, all other green house gases are given GWP values derived from [http://en.wikipedia.org/wiki/Carbon_dioxide_equivalent CO<sub>2</sub> equivalence]. GWP is the potential [http://en.wikipedia.org/wiki/Global_warming global warming] effect of a mass of GHG over a specific time period.<ref> | CO<sub>2</sub> is the standard by which all other [http://en.wikipedia.org/wiki/Greenhouse_gas green house gases] (GHG) are measured. With a [http://en.wikipedia.org/wiki/Global_warming_potential global warming potential] (GWP) value of one, regardless of the time period, all other green house gases are given GWP values derived from [http://en.wikipedia.org/wiki/Carbon_dioxide_equivalent CO<sub>2</sub> equivalence]. GWP is the potential [http://en.wikipedia.org/wiki/Global_warming global warming] effect of a mass of GHG over a specific time period.<ref> | ||

| Line 131: | Line 124: | ||

=== Results === | === Results === | ||

Following the RCEA retrofits there was a reduction in kilowatt hours consumption at Leon's. Actual energy savings exceeded projected values by one percent. Though there were many variables to power usage, it is reasonable to assume that much of the power savings was directly related to the RCEA retrofit. 10 months after the RCEA retrofit Leon's was inspired to perform their own lighting retrofit, leading to even greater energy savings.'''(which were what????)''' | Following the RCEA retrofits there was a reduction in kilowatt hours consumption at Leon's. Actual energy savings exceeded projected values by one percent. Though there were many variables to power usage, it is reasonable to assume that much of the power savings was directly related to the RCEA retrofit. 10 months after the RCEA retrofit Leon's was inspired to perform their own lighting retrofit, leading to even greater energy savings.'''(which were what????)''' | ||

<br> | <br> | ||

== | ==Future Retrofits== | ||

Leons is considering replacing one of their two piston-run air compressors with a [http://en.wikipedia.org/wiki/Rotary_screw_compressor Rotary Air Compressor]. This would decrease energy consumption in addition to decreasing shop noise and improving air pressure consistency among the pneumatic tools. The air compressors are the main source of energy for the power lifts used in the shop to raise vehicles for service. They run almost constantly in the enclosed shop creating a substantial amount of noise and are a significant source of the shops energy consumption.<br /><br /> | Leons is considering replacing one of their two piston-run air compressors with a [http://en.wikipedia.org/wiki/Rotary_screw_compressor Rotary Air Compressor]. This would decrease energy consumption in addition to decreasing shop noise and improving air pressure consistency among the pneumatic tools. The air compressors are the main source of energy for the power lifts used in the shop to raise vehicles for service. They run almost constantly in the enclosed shop creating a substantial amount of noise and are a significant source of the shops energy consumption.<br /><br /> | ||

General Manager Dale Warmuth is conscious of the impact that energy use has on his business, and is delighted at the savings that his company sees in their efforts to improve efficiency both financially and ecologically. Mr. Warmuth has seen a 33% decrease in consumption since the retrofits'''(his number or yours?). '''He is satisfied with the level of service that he has recieved from RCEA, and continues to pursue new and more efficient practices. <br><br> | General Manager Dale Warmuth is conscious of the impact that energy use has on his business, and is delighted at the savings that his company sees in their efforts to improve efficiency both financially and ecologically. Mr. Warmuth has seen a 33% decrease in consumption since the retrofits'''(his number or yours?). '''He is satisfied with the level of service that he has recieved from RCEA, and continues to pursue new and more efficient practices. <br><br> | ||

| Line 152: | Line 143: | ||

== References == | == References == | ||

<references /> | <references /> | ||

[[Category:Engr115_Intro_to_Engineering]] [[Category:RCEA_energy_audit_reviews]] | [[Category:Engr115_Intro_to_Engineering]] [[Category:RCEA_energy_audit_reviews]] | ||

Revision as of 01:51, 7 December 2009

Energy Efficiency Retrofit For Leon's Car Care Center

Lighting accounts for 20% to 50% of the energy consumed by a commercial building.[1] In June 2008 the Redwood Coast Energy Authority (RCEA) completed the first phase of a lighting retrofit for Leon's Car Care Center with the replacement of 40 fluorescent light fixtures. The second phase saw the installation of an energy miser to reduce electrical consumption of the vending machines in the office. Leons completed the final phase of the retrofit independent of the RCEA with the replacement of 32 metal halide light fixtures in the shop area.

Building History

Leon's Car Care Center (Figure 1) is a family owned and operated business that has been in Eureka, California for over 48 years. Since 1992 Leon's Car Care Center has been located in a steel I-beam shop structure with an attached wood frame office, built new to their specifications. The building was designed to utilize windows built into the upper reaches of the structure allowing natural light to penetrate to the main shop area and decrease the reliance on electric light.

Electrical Demand

Automotive repair requires the use of power tools and computerized diagnostic equipment in addition. The tools use more energy to operate, but are used sporadically, whereas lights are on continuously. The shop is equipped with 8 vehicle lifts, two air compressors, and computers for diagnostic repair. These lights were supplemented with wall mounted fluorescent lights for work bench and lower applications. The office is illuminated with fluorescent lights, contains computers, two climate control units, one cold soft drink vending machine and a snack vending machine.

Redwood Coast Energy Authority (RCEA)

The RCEA is a Joint Powers Authority (JPA) commissioned by seven local municipalities under contract with PG&E to promote energy efficiency.[2] The organization is funded through taxes collected by PG&E and the CPUC. The RCEA also operates under a smaller contract with the US Department of Energy (DOE) to promote solar energy use.[3]

Redwood Coast Energy Watch (RCEW)

The Redwood Coast Energy Watch (RCEW) is a $1.6 million partnership program between the RCEA and the Pacific Gas and Electric company (PG&E) responsible for the project. Funded by the California Public Utilities Commission (CPUC) public goods charge, the RCEW is responsible for the energy efficiency upgrades at Leons Car Care Center and other area businesses.

Retrofit Hardware

Fluorescent Lighting

Two Lamp T8 In Office

New Fluorescent Lamp Ballast Energy Conservation Standards (10 CFR, Part 430) were set in 2000 by the DOE establishing a new minimum Ballast Efficacy Factor (BEF) effectively discontinuing production and sale of the T12 ballasts in the United States by 2005.[4] The 40 watt T12 ballasts are replaced by a 36 watt T8 ballast, producing the same amount of light while using less electricity.[5] The fixtures installed by the RCEA contain NEMA (National Electrical Manufacturers Association) certified T8 electronic lamp ballasts reducing rated consumption by an additional two to five watts.[6] Older magnetic ballasted fixtures have a noticeable flicker that can reduce efficiency of the lamp by up to ten percent.[7]

All of the existing two lamp fluorescent fixtures in the shop and office (Figure 2) were replaced by the RCEA during the first phase of the retrofit. 31 electronic and nine magnetic T12 ballasted fixtures have been replaced with T8 ballasted fixtures at this time. During the final phase of the retrofit Leons replaced 32 400 watt High Intensity Discharge (HID) metal halide lamps (Figure 3) with six lamp T8 ballasted fluorescent fixtures (Figure 4). Metal halide lamps can cost 50% more[8] to operate than the T8 electronically ballasted fluorescent fixtures.

-

Figure 3.

HID Metal Halide -

Figure 4.

Six Lamp T8 -

Figure 5.

Energy Miser

Energy Miser

The RCEA has overseen the installation of an energy miser (Figure 5) on the snack and cold drink vending machines in the office. The miser acts as a motion sensor in conjunction with a timer that shuts the appliances down after a period of inactivity. According to retailer Austin Energy,the potential savings from an energy miser on a cold drink machine is 40% and 80% on a snack machine.

Data Analysis

To determine whether or not the RCEA retrofits had reduced power consumption at Leons, electrical consumption was compared before and after the retrofit(Figure 6). The time period from June 2008 to March 2009 was selected to reflect power consumption changes as a result of the RCEA retrofit. The time period was limited to ten months because in April 2009 Leons replaced multiple metal halides with fluorescent lights. The time period from June 2007 to March 2008 was selected as a comparison period before the retrofit. Analysis of the data showed that after the retrofit, electrical consumption went down from the previous year.(should also compare the Leon retrofits at least graphically use different series for each time, don't use grey backgrounds in graphs.)

| Project Summary[11] | |

| Total Installed Cost: | $2,046.49 |

| Instant Rebate: | $642.60 |

| Estimated Savings: | $389.20 per year |

| Estimated Monthly Savings: | $32.43 |

| Simple Payback: | 3.6 years |

| Return On Investment: | 28% |

| Power Reduction: | 1.08 kW |

| CO2 Emissions Reduction: | 1,213 lbs/year |

Predicted Versus Actual Savings

We compared the RCEA predicted savings with the savings we calculated using power consumption data. Since the RCEA made predicted savings based on a time period of one year, and our comparison was confined to a 10 month period starting in June 2008 running till March 2009, there was an adjustment that was necessary. To compare like quantities of time, total kWh from the 10 month period was divided by 10 to get a monthly kWh figure. The monthly kWh figure was then multiplied by 12 to give an estimated yearly kWh total. Below is a comparison of the predicted savings versus the savings shown after analyzing the data.(combine with CO2 Table, only have two columns, A1)

| Projected | Actual | |

|---|---|---|

| Savings ($/year) | 389.20 | 392.22 |

| CO2 Reduction (lbs/year) | 1213 | 1222 |

| Energy Savings (kWh/year) | 2,334 | 2,352 |

Carbon Dioxide (CO2) Emissions

CO2 is the standard by which all other green house gases (GHG) are measured. With a global warming potential (GWP) value of one, regardless of the time period, all other green house gases are given GWP values derived from CO2 equivalence. GWP is the potential global warming effect of a mass of GHG over a specific time period.[12]

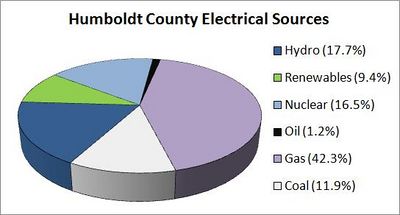

Kilowatt hours (Kwh) can be equated to pounds of CO2 emitted in relation to the various processes involved in the production of the electricity. Humboldt County's electricity comes from a number of sources(Figure 7) [13] (Table). Pounds of CO2 per Kwh varies from source to source, e.g. coal produces an estimated 2249 pounds per Kwh from burning coal directly, whereas any emission of CO2 related to the production of nuclear energy is related to uranium mining processes.[13] The RCEA uses the value generated by PG&E (the electrical supplier) of .524 pounds of CO2 per Kwh.[14]  (should do electrical use this way also. what about period after HIDs were installed?)

(should do electrical use this way also. what about period after HIDs were installed?)

Results

Following the RCEA retrofits there was a reduction in kilowatt hours consumption at Leon's. Actual energy savings exceeded projected values by one percent. Though there were many variables to power usage, it is reasonable to assume that much of the power savings was directly related to the RCEA retrofit. 10 months after the RCEA retrofit Leon's was inspired to perform their own lighting retrofit, leading to even greater energy savings.(which were what????)

Future Retrofits

Leons is considering replacing one of their two piston-run air compressors with a Rotary Air Compressor. This would decrease energy consumption in addition to decreasing shop noise and improving air pressure consistency among the pneumatic tools. The air compressors are the main source of energy for the power lifts used in the shop to raise vehicles for service. They run almost constantly in the enclosed shop creating a substantial amount of noise and are a significant source of the shops energy consumption.

General Manager Dale Warmuth is conscious of the impact that energy use has on his business, and is delighted at the savings that his company sees in their efforts to improve efficiency both financially and ecologically. Mr. Warmuth has seen a 33% decrease in consumption since the retrofits(his number or yours?). He is satisfied with the level of service that he has recieved from RCEA, and continues to pursue new and more efficient practices.

Related Links

http://www.redwoodenergy.org - Redwood Coast Energy Authority (RCEA)

http://www.leonsmufflers.com - Leons Car Care Center

http://www.energy.gov/ - The US Department of Energy (DOE)

http://www.energy.ca.gov/ - The California Energy Commission (CEC)

http://www.cpuc.ca.gov/ - The California Public Utilities Commission (CPUC)

http://www.aboutlightingcontrols.org/index.shtml - Lighting Controls Association (LCA)

http://www.eere.energy.gov/ - The US DOE site for energy efficiency and renewable energy

http://www.eia.doe.gov/index.html - The Energy Information Administration (EIA) site for official energy statistics

References

- ↑ http://en.wikipedia.org/wiki/Lighting#Energy_consumption

- ↑ http://www.redwoodenergy.org/ContentPage.asp?ContentID=92

- ↑ http://www.energy.gov/energysources/solar.htm

- ↑ http://www.aboutlightingcontrols.org/education/papers/ballast_law.shtml

- ↑ http://wood.bigelowsite.com/articles/fluorescent_lamps_and_ballasts.htm#Differences%20between%20T8%20and%20T12%20lamps

- ↑ http://www.aboutlightingcontrols.org/education/papers/2008_nemaballasts.shtml

- ↑ http://en.wikipedia.org/wiki/Fluorescent_lamp#Ballast

- ↑ http://www.aboutlightingcontrols.org/education/papers/high-low-bay.shtml

- ↑ http://www.fluorescent-high-bay.com/products/Flat-Profile%2C-6-Lamp%2C-T8%2C-Fixture.html

- ↑ http://www.google.com/imgres?imgurl=http://www.farmtek.com/wcsstore/EngineeringServices/allbizunits/prodimages/full/104012a.jpg&imgrefurl=http://www.farmtek.com/farm/supplies/prod1%3Bft1_lighting_fixtures_bulbs-ft1_metal_halide_bay_fixtures%3Bpg105713.html&usg=__nq2AUwdIBCUaZpJYGotDe3SHEZg=&h=220&w=220&sz=4&hl=en&start=18&tbnid=YLdDT8Af4acDQM:&tbnh=107&tbnw=107&prev=/images%3Fq%3Dhigh%2Bbay%2Bmetal%2Bhalide%26hl%3Den%26client%3Dfirefox-a%26rls%3Dorg.mozilla:en-US:official%26hs%3DOVm%26tbo%3D1

- ↑ Calculations based on average cost of $0.01667 per kWh and 09Com-600-SFL-170-CFL-60-CTR rebate

*Project Summary courtesy of RCEA Program Manager: Dana Bourdreau, Auditor: Budd DickinsonfckLR - ↑ http://en.wikipedia.org/wiki/Global_warming_potential

- ↑ 13.0 13.1 http://www.epa.gov/cleanenergy/energy-and-you/how-clean.html

- ↑ http://www.pge.com/about/environment/calculator/assumptions.shtml