What is the physical preparation ?

The physical preparation of plastic are all the different steps the plastic waste needs to undergo to be transformed into small, clean and dry chips, of acceptable sizes to allow to be introduced into the machines for shaping. These different steps are the sorting, washing, drying and grinding. Sorting precedes grinding [1] Indeed, it is easier to separate the large pieces than the small ones. Washing and drying can however be done at different times, depending on the type of treated deposit and the available technologies. The different scenarios are shown in the diagram below:

a. Wash before the sorting Execute the washing before any other treatment step is the ideal way to achieve sorting in good working conditions and hygiene. It is however not much performed because it requires to clean all the waste, including that which is not going to be recycled. Only the approaches recycling a large variety of plastics or only treating one type of waste can make use of this technique. Whatever is chosen, a primary scouring at the source of the highly fouled waste may be necessary. It can be done using a dry hard brush.

b. Defouling before the pre-cutting After the sorting, the pre-cutting of waste of large sizes is necessary to ensure that it does not stick to the blades of the grinder (bottles, flasks, ...). Notably in the case of flasks, it is advisable to first perform a defouling step which consists of removing the caps, labels, removing residue and rinsing well.

c. Washing before the grinding Executing the washing before the grinding is the easiest and the most practiced method. The sorted plastic waste is washed by hand in buckets with cold or warm water. The use of soap or detergent facilitates the task. In case of heavily soiled waste, warm water may be useful but the water temperature remains limited because the waste is handled by hand.

d. Washing after the grinding The wash after the grinding consists of vigorously shaking the grinded plastic flakes in basins of water. The friction between the particles releases dirt. This practice allows a degree of mechanization. The use of very hot water and powerful cleansing agents such as sodium (or potassium hydroxide) is then possible because the operators are not in direct contact with the materials. It is however necessary to comply with minimum safety rules.

1. Wash before the sorting ||Systematic washing of all the collected waste. It can be limited to a simple dry scouring using hard brushes. ||Hygiene for future treatments, including the sorting. The dry scouring facilitates the sorting and reduces the quantity of water for the future washing. ||Unnecessary washing for non-recyclable plastic.| Method | Description | Advantages | Disadvantages |

| 2. Defouling before the pre-cutting | Technique specific to the recycling of bottles and containers consisting of the removal of all fouling elements from the bottles (labels, caps, residues, ...) | Limits fouling (color and plastics). Recovery and use of residues is possible. More easy to achieve before than after pre-cutting. | Long step. Requires some investment and creativity. Is only executed in the case of large deposits of vials. |

| 3. Wash before the grinding | Washing per batch of sorted waste. This washing is done by hand with water and sometimes added soap or detergent. | Requires little equipment. Fast drying due to small surface. A sorting can still be done after the washing. | Labor-intensive. Hard work. A mechanization is difficult to implement. Temperature of the water is limited. |

| 4. Washing after the grinding | Washing of chips resulting in a grinding of presorted waste. This wash may be done in large water basins (possibly hot) with added of cleansing agents such as soda. | Mechanization of the process is possible which makes the work more comfortable. The use of very hot water and cleansing agents facilitates the scouring. | Mechanization requires some investment costs. The costs of consumables are also greater. Slower drying because the surface to dry is greater. Does no longer require separation (except in individual cases) |

Table 4.1: Enumeration of washing options.

The classical approaches and those that are the easiest to implement operate according to the scheme: sorting-defouling-precutting-washing-drying-grinding. At the end of this chapter, the steps are outlined in this order. It will be important to the initiator of the project to define his treatment approach based on the characterization of his deposit and the previous criteria.

Location of the recycling center

The executed processes in the physical preparation of the plastics and the shaping (see chapter 5) requires a minimum of space and infrastructure as described in the following paragraphs. Before putting them in place, we must consider the location of the center.

- For the transport costs reason already mentioned above, we will place the center as much as possible to the center of the collection area to maximally reduce the displacement of materials.

- Similarly, proximity to places where the recycled matter can be gotten rid off is a added advantage. Processing companies for semi-finished products (flakes, granules ...), markets and commercial zones for recycled objects.

- However, it is best to avoid localisation in an densely populated area. The recycling of plastic waste is indeed an activity that generates pollution: noise, vibration, odors, dust, ... This is not always obvious, especially as the waste is usually collected in these areas. Agricultural areas and cattle rearing areas are also discouraged.

Besides these considerations, the center must have:

- A network of electric power supply (monophase - triphase ?), available wattages (110 V, 220 V, ... ?), ease of connection, price per kilowatt, frequency of power cuts, ... In case of too frequent powercuts, we must opt for a generator.

- Accessibility to water. The recycling of plastics indeed requires significant quantities of water for the washing of the waste: about two liters per kilo of waste. The cost of water, accessibility and good management are factors that may be essential. It is an added advantage to have a well or to be near a river. In urban areas, we must often settle with tap water (expensive). It is then important to use it rationally and recycle it maximally.

- Accessibility by all kinds of vehicles.

Note: In countries where the recycling of plastics is already introduced, all the preparation steps of plastics can not be performed in one center, but in different centers specialized in one or another step. Thus is also the case in Cairo (Egypt) and Bangalore (India). Here, there are sorting, washing, grinding, ... centers amongst whom plastics are sold at different preparation steps.

Sorting

Why sorting ?

The theoretical concepts on the polymers in the first chapter showed that they were immiscible, that is to say we can not combine them together for recycling. It is therefore necessary to sort them before recycling. Although a multitude of methods have been devised to automatically separate plastic, only the manual sorting using visual recognition provides a good separation at reasonable costs. Unfortunately, plastics all appear alike and the recognition is not always obvious. The various criteria given in the first chapter will be useful, but it is certain that it is primarily experience that will give best results. When in doubt, it is better to discard a piece of plastic than to try to recycle it, than to risk contaminating a batch and compromising the quality of the finished products. This is summed up in one phrase that all sorters must bear in mind: Template:Cquote

How to sort ?

There is no universal recipe for sorting plastic waste. The manager of the sorting center will naturally find most suited methodology to the local situation. The following paragraphs give an idea of the different separations that can be achieved from a heterogenic deposit of plastic waste.

a. Sorting by origin The waste is more or less soiled by their origin (see chapter 3). Thus, the waste collected at the source is always cleaner than that obtained from the street or landfill. It is thus useless to mix them. Sorting by origin of plastic waste is usually spontaneously done upon the receiving of the waste by the center. The heavily soiled waste will be dry scoured with a brush before undergoing an additional sorting. This will be greatly facilitated.

After the sorting and washing is completed, the plastics of the same type, but of different origins can be mixed and processed together. This practice is nevertheless uncommon. Recyclers prefer to keep them separated so as to be able to offer plastics of different qualities (with adapted prices).

b. Sorting by main category of waste By main category of waste we define: films, large objects (chairs, pots, basins, ...), bottles, shoe soles, ... The separation of waste according to some well-chosen categories is often useful for several reasons:

- All the waste does not necessarily undergo the same type of treatment (washing, grinding, shaping). Thus, the films will not be grinded together with the other plastic objects, even if they are made from the same polymer. Similarly, objects larger than that of the opening of the grinder will undergo an additional step of precutting (see the paragraph below).

- Sorters may specialize in sorting a clearly defined category of waste. The experience they gain while perform this task allows them to greatly improve performance and capability in separation.

- The separation of plastics by their shape is also a useful step. In fact, some additives are added specifically to polymers to give them properties that facilitate their shaping: injection, extrusion, blow-injection, ... (see chapter 5). The recyclers thus prefer to separate them in order to preserve these properties. They may in turn sell the plastic pellets specifically for one or another other transformation technique. The criterion for separation is the scar that remains after an object has been shaped (see chapter 2). In Kinshasa, for example, the recyclers require sorters to separate the caps (injection) from their bottles (blow-injection) to recycle them separately.

- The "pre-sorting" can also eliminate much of the "non-recyclable" waste amongst which we find:

- Too soiled waste;

- Thermosetting and thermoplastic polymers (see Chapter 1);

- Infiltrated waste (metal, wood, cardboard, ...).

- Instead, some waste can be reused (after refurbishing) rather than being recycled. It is useful to directly separate them from other waste. In Yaoundé (Cameroon), for example, 30% of the collected sandals are refurbished and resold to the public in the second-hand market.

When the collection of waste plastics is done by motivated supplying, the pre-sorting is generally realized upon receival because the amounts of compensation are often fixed according to their category.

c. Sorting by category of plastic The differentiation of plastics by type is done using the criteria described in chapter 2. In general, 90% of the plastic can be directly recognized based on sorting experience. These are thus rapidly separated. The remaining 10% will require testing to be recycled. Tests obviously take considerable time and greatly slow production. In general, the major types of plastics (HDPE, LDPE, PP, PVC, PS) are sorted first. The others are stored in a container for a future separation if markets for these products exist. Do not forget to properly remove the thermosetting polymers from the rubbers which are little appreciated by recyclers and may devaluate the batches sorted plastics.

d. Sorting by color Finally, sorting by color is the final step of sorting that can be performed. It is obviously one of the easiest, but without which the recycled plastics have a grayish or brownish color, which is difficult to sell. All varieties of colors should not be separated. In general, we sort them on a number of tones, for example:

- the light ones;

- whites;

- reds, yellows, oranges, ...

- browns, blacks, greens, ...

- blues.

Once grinded, mixed and regranulated, we get relatively homogeneous colors. For the films, it is essential to do at least the sorting between the colored and the transparent ones of which the value of recovery can be much greater.

Implementing the sorting Sorting is a stressful job. It is therefore advisable to provide the best working conditions, avoiding, for example, working on the floor. Sorting tables can be brought into sheltered rooms. Some well equipped centers dispose of conveyor belts. The plastics thus circulate before the sorters whose job it is to take out a specific type of plastic. The remaining plastics are then tested by other sorters. The stockpiling of sorted plastic on the floor is discouraged: it provokes fouling and the plastics can be mixed again. It is essential to always place them in bins or bags!

Human resources: The experience of sorters is crucial. Two weeks of learning are usually sufficient for a person to work in a sorting center. During his training, the new sorter first starts by separating plastics by color in order to familiarize himself with the business. He will then learn the sorting of plastics by type by learning to use the recognition tests. It is difficult to put the daily production capacity of a sorter in numbers. It indeed depends on many factors: types of plastic to separate, local conditions, ... Also the separation of films, with a low density, is also much slower than that of large objects. Similarly, the pace and work schedules may vary significantly from one country to another. To give an order of magnitude, we can consider that a person can sort about 80 kg of plastic waste per day. However, it is not uncommon to find people able to sort 160 kg of plastic by day. Sorting is repeating and boring work for which it is difficult to remain attentive. After a few hours, some errors may be committed. The quality of sorting is then directly affected so it is important to take this into account and to take a few minutes rest. If a batch of plastic has been sorted, one of the best sorters must perform a check to assess its quality. An error margin of 5% of poorly sorted thermoplastics can be accepted (one plastic per 20). Otherwise, the batch must be resorted. The tolerance for thermosetting plastics or rubber is way lower.

Material:

- Cutters, knives or other sharp tools used to open the bags. Pairs of gloves are essential for handling waste and masks to avoid the inhaling of dust.

- All necessary equipment for the separation tests:

- Flame test: a cutting tool, a lighter, an inflammable surface (ashtray, for example), a copper wire for the recognition of PVC.

- Density test: transparent containers, a cutting tool, salt, alcohol (ethanol, methanol or propanol), a hydrometer.

- Thermoplastics/thermosetting polymers: a wire and a lighter.

- For the packaging, large bags are used. Labels indicating the plastics they contain must be used. Large bins are sometimes used for intermediate stages of sorting.

- Always have scales in order to weigh the sorted plastic. The weight will allow one to calculate their value and establish the method of treatment. The "balance rod" is easier to handle if bags are used for packaging. If bins are used, we prefer the "weighing scales".

- All ideas are good to improve the screening: construction of sorting tables, conveying waste ... It can also be useful to establish a database of frequently encountered visual objects. A copy of each kind may for example be placed prominently on a shelf with a label clearly indicating the plastic from which it is made.

- A space or a container shall be foreseen for the residue, ie all non-recoverable waste, the quantity varies depending on the type of established collection system. On average, only about 10% of the collected waste can not be recycled. We must therefore get rid of it using the best possible method, the ideal is to have a landfill near the sorting centre. It is possible that some waste can not be recycled at a given moment, but can be in the near future. It is then wise to store it in order to recycle it once the recycling approach has been set up.

Important Note: As with any waste, Plastic waste tends to transfer infectious diseases. They are indeed an ideal niche for flies, mosquitoes and rodents. This is especially true when the sorting is done before the washing. Sorters are then directly in contact with the stockpiled waste, it is recommended that they are properly vaccinated (tetanus, hepatitis, rabies, ...).

The washing and the drying

The washing is a crucial step in a recycling project. The presence of impurities can strongly affect the quality of recycled products, and therefore the resale prices. All plastic waste must be cleaned except perhaps some industrial waste with a very low degree of soiling. For the others, a preliminary defouling step is sometimes necessary. This is the case with vials, unto which the first part of the chapter is devoted. Finally, a forced drying is necessary because plastic recycling machines require working with materials that no longer contain any traces of humidity.

Decontamination: Decontamination is a process related to the recycling of bottles. Traditionally, they consist of a main body, a cap and one or more labels. Moreover, they often contain a residue that must be drained.

a. Emptying It is sometimes interesting to empty vials and collect the residues. This is the case with bottles that contained detergents, soaps, shampoos and other cleansing products. After rinsing with hot water, soap and water will be used in in the wash basins. Vials that have contained oil will be drained by simply turning them on a corrugated iron placed in the sun (see figure below).

The oil thus collected in a container can for example serve as a lubricant for different processing machines (see chapter 5). This technique has been widely practiced in Cuernavaca (Mexico).

b. Decapping It is necessary to remove caps and rings. They generally have different colors from those of the bottles and can be made from another type of plastic. They are obviously identified, sorted and washed so as to be recycled separately.

c. Delabelling Two types of labels can be fixed to the containers: paper labels that are glued and printed and plastic films that surround the bottle. Plastic film labels can be easily removed with a cutter. The paper labels are more difficult to remove. Cold, they tear and leave a thin layer of paper. It is best to soak them in hot water for a certain period of time. Another technique is to warm up the bottle from the inside with steam to soften the glue. The label is then easily removed and also in one piece. The remaining glue on the bottle is acceptable. The figure below illustrates one possible method to introduce steam into the vials.

Washing

Like sorting, washing is a treatment step that requires a entensive labour. It is hereby not intented to clean up the waste impeccably, but rather to find the right compromise for the required quality. The different washing techniques are described below in ascending order of washing quality, and forthfluing cost.

a. Dry brushing When the waste is too soiled, notably by sand, earth or organic waste (waste from streets, parks, landfills, ...), a first dry scouring allows to not make the washing water too polluted (to conserve water). The scouring is usually done using stiff brushes. This practice generates a lot of dust in the air. It is therefore essential to have a mask to avoid inhalation.

b. Manual wash Hand washing is done in large basins or half-barrels with a capacity of minimally 100 liters. According to the tenacity of the dirt, different techniques can be put to work:

- For relatively clean waste, only soiled by dirt or dust, washing in cold water is sufficient. Plastics are vigorously rubbed with bristles.

- For highly soiled and greased waste, the wash should be done in hot water with the addition of soaps or detergents. The water temperature remains limited because the waste is washed manually.

- When the use of detergents is not sufficient, you can also use caustic soda (NaOH) or potassium hydroxide (KOH), notably for removing grease and oil residues. A soaking time of several hours (sometimes more than one day) in trays allows to correctly scour off the waste. They are then scrubbed and properly rinsed. This technique is nevertheless unrecommended for hand washing as these products are relatively dangerous to handle. If this option is chosen, however, it is important to take into account the considerations mentioned in the following paragraph.

Precautions for the use of sodium When using NaOH or KOH, to make sure the washing is done with long, solid rubber gloves, without holes as well as with waterproof work coats and goggles. Also avoid any spilling. In case of contact with skin or eyes, rinse with water for ten minutes. When in a solution, avoid inhalation or ingestion. In case of ingestion, breathe fresh air. If swallowed, drink plenty of water. If discomfort or pain persists, consult a doctor.

Human resources: The daily capacity of of washing for a person is very variable. We estimate that it is between 50 and 100 kg depending on the degree of soiling of plastics, the type of washing done and the local labor conditions. Washing does not require an experienced staff such as with sorting. The work is less stressful and all options to make it easier can be foreseen. Thus, it is better to allow the washers to work standing, or sitting, without bending too much. Similarly, water supply via a storage tank placed vertically avoids the slow and tiring filling of the wash basins with buckets. When handling waste (before and after the washing), we must make sure not to mix plastics that are already sorted.

Material:

- Basins or large washing containers with a minimum capacity of 100 liters. Experience shows that many centers use drums cut in half on which two handles are welded. It takes at least one per washer. Buckets and pipes are also needed to convey the water.

- Hard brushes, waterproof gloves, waterproof work coats, goggles (if using soda), chairs and other equipment facilitating the work of the washers.

- A hot water system when washing with hot water.

- Permeable or perforated bags to drain the washed plastics before drying them.

Consumables: The main consumable for the washing is water. We consider it necessary to have about 2l per kg of plastic.

- The amount of detergent or soap depends on the quality. Detergents are expensive products: we will thus be careful not to waste it. In general, detergents from powder are less expensive than liquid detergents. When detergent residues can be recovered from the collected vials, we will use them with priority. Adding additional detergents is only done if necessary.

- Caustic soda (NaOH) or potassium soda (KOH) are products commonly used in businesses. It is normally possible to get them easily. Their prices can still vary significantly depending on the location and the ordered quantity. One tonne of NaOH is costs less than 300€ (0.3€/kg) in virtually any port, a bag of 25 kg costs 15€ in Lome, Togo (0.6€/kg) and a bag of 1 kg costs 2.25€ in the markets of Kinshasa (DR Congo). The quantity to be used obviously depends on the level of fouling of the plastic to be washed. For safety reasons, it is however better to not exceed certain concentrations. As an example, Egyptian washers use about 12.5g KOH per liter of water.

Water management: We have seen it, water is used in large quantities for washing. For example, a wash of 500 kg of plastic per day requires about 1m³ of water. Good management herein can help to reduce costs significantly. A first consideration is the accessibility to water. Several possibilities of supply are:

- A simple way to have cheap water is to collect rainwater in barrels of a large capacity. This is obviously usable in countries where there is regular and abundant rainfall. Whatever the case , another source of supply must be added to remedy the lack of water during dry periods.

- If the situation permits, the possibility of having a well is obviously interesting. The extraction of water with a bucket is too challenging or impossible to obtain the required flow. It is more reasonable to use a pump. For reasonable flow rates (10 to 20l/min), manual pumps can be used [2] For higher flow rates, an electric pump is necessary.

- The washing of plastic does not require water of quality. Clear river water can be quite sufficient.

- Finally, when no other source of supply is available, one must resolve to using tap water, which directly influences the washing costs. Particular attention will then need to be given to avoid wastage.

A second way to manage water is to use a washing "against the current". This involves passing the waste into a series of successive bins in which the water becomes successively cleaner. From the other direction, clean water flows, that is to say from the cleaner tank to the foulest tank. As such, the dirty water rubs against the dirty waste and the clean water serves to complete the work. The bins are preferably placed in steps so that the water can circulate due to gravity. The waste, meanwhile, is taken out from the basins by the washers until they have attained the required cleanliness.

Finally, the treatment of wastewater is an effective way to limit the water consumption. When the soiling of the plastics principally consists of sand or dirt, this can be done easily by moving all of the wastewater into a tank or a settling basin. Their principle is very simple. Water carrying more or less fine particles find themselves in a resting state. The sediment particles settle unto the bottom of the basin. The clear surface water is recovered by simply creaming it off. When the layer of mud at the bottom of the basin is too thick, we must proceed to emptying the water and the mud. The basin is then once again operational.

c. Washing of flakes The use of hot water for the washing is not common for large waste. It is very however very easy when they are have already been grinded (see paragraph 5). The plastic flakes can be placed in boiling water tanks in which detergent or soda is added. A regular mixing causes friction between the plastic and the dirt. After a more or less long settling time (several hours for soda baths), the flakes are extracted using bins with large skimmers. After rinsing with clear water, they can be dried.

Drying

During the recycling, the plastics are melted in appropriate machines (see chapter 5). Whatever they are, their melting temperatures are higher than 100°C, so the temperature of boiling water. Thus, if the plastics are introduced wet into these machines, the water will return to the state of vapor and form bubbles in the recycled plastic. The steam can also change the chemical properties of the plastics. Moreover, if the degree of humidification is high, the expansion during the evaporation can cause significant mechanical disturbances causing breakage to the machinery. We thus see that drying is necessary, up until a much lower moisture content (less than 0.1%!). For reference, humidity is the quantity of water expressed in percent, that the matter contains. It is found by weighing a sample before and after drying [3]:

Failed to parse (Conversion error. Server ("https://wikimedia.org/api/rest_") reported: "Cannot get mml. TeX parse error: Double subscripts: use braces to clarify"): {\displaystyle Humidity(\%)=M<sub>humid</sub>-M<sub>dry</sub>/M<sub>humid</sub>_{X}_{1}00}

with:

- Mhumid: the weight of the material before drying

- Mdry: the weight of the material after drying

The amount of water that the matter can hold is proportional to the specific surface. That of plastic objects is much lower than that of grinded plastic flakes. It is therefore necessary to consider drying them separately.

a. Drying of objects The shape and the size of the washed plastic objects do not allow to foresee a mechanization for forced drying. After draining, different types of drying may be put in place. Whatever the case, the drying time always depends on 2 parameters which are temperature and ventilation.

- Drying in the sun: solar energy is obviously the least expensive in countries where there is much sunlight. Films can be hung on wires, like linen. The objects are more spread out and turned regularly to expose all the sides to the sun. Placing them on grids or nets at a certain height allows to finish the draining. All the drained water does not need to be dried.

- The ventilation: when the sun alone is not sufficient and the wind is low in strength, an artificial ventilation (fan) will speed up drying.

- A ventilated room: in regions where outdoor drying is not possible, there is no other solution than drying in premises. A simple covered interior yard may suffice. It will provide the necessary ventilation to reduce the drying time.

- The hot air: the drying by hot air can be done independent of climatic conditions. Different techniques are possible (heat guns, electric dryers, other artisanal ideas, ...). All combine a heat source (burner, electrical resistance, ...) and a ventilation system. These techniques are obviously a cost to be calculated in.

b. Drying of flakes The drying of flakes can be more easily mechanized. Thus, after a good draining, the wet flakes can be drained in a drainage basket. A recycled washing machine perform this task. Drained flakes of a size between 4 and 10 mm have a moisture content of about 5%. After a spin of a minute in the basket of a washing machine, the moisture content is reduced to 0.5%. The flakes can then be completely dried within an hour of exposure to sunlight. We may expand this to about 15 kg/m². Too avoid having to clean the basket with each spin, place the flakes in bags, or burlaps. This also avoids pollution when plastic flakes of different sorts or colors remain in the drum. If the weather does not allow the drying in the sun, different solutions can be found: a covered and ventilated area, dry hot air, ...

For more information on the drying: To install drying, it is possible to draw upon a one of the many books published on the drying of foodstuffs such as "Guide d'aide à la décision pour la création d'unités artisanales de séchage agroalimentaire", edited by GERES (Groupe Energies Renouvables et Environnement). 40, rue Saint Jacques 13006 Marseille (France) Tel: 00 33 (0) 4 91 37 21 53 Email: eie.marseille@free.fr http://geres.free.fr

This guide contains: - A description of the methodology for the construction of a drying facility; - Fact sheets of the main drying technologies; - Food for thought for optimization of drying. It is available in French and English for the sum of 19 € + 5 € shipping fee (downloadable order).

Another helpful guide is entitled "Le sécharge solaire à petite échelle des fruits et légumes", published by GRET (Groupe de Recherche et d'Echange Technologique). 211-213 rue La Fayette 75010 Paris-France Tel: 00 33 (0) 1 40 05 61 61 Fax: 00 33 (0) 1 40 05 61 10 E-mail: gret@gret.org Web: http://www.gret.org

This guide provides practical and methodological elements to start or improve a solar drying activity. It also offers synthetic sheets on existing dryers. It is available for a fee of 3.8 € + 3,05 € for shipping.

Downsizing

Pre-cutting

Pre-cutting is a necessary step prior to the grinding of large waste and hollow objects that have trouble of being picked up between the blades of the grinder (bottles, cans, ...). Moreover, after the precutting, the density of the waste is well above the initial density, which improves the performance of the grinders. To minimize transportation costs, pre-cuttings must be done as early as possible, notably in case of long transports between the collection sites and the grinding site. It can be for example done on collection sites or transfer sites.

a. knives The most obtainable and least expensive cutting tools are obviously knives or other sharp objects such as cutters or machetes. Their employment however is exhausting and does not permit a high production rate. Moreover, when the thickness of the objects to be cut is large, the cutting becomes very difficult to achieve.

One solution is to partially melt the plastic by heating the blade. This is detrimental to the quality of the plastic.

b. scissors Scissors are a cheap alternative to cutting. Rather than the simple pair of traditional scissors that limit the possibilities of fast cutting, we prefer a system mounted on a sturdy mount and fitted with a long enough arm lever. In Cairo, this type of tool can cut about 50 kg of plastic waste per hour.

c. a jigsaw Jig saws or rotary saws are pre-cutting tools that are far more comfortable. Being widely used in the workshops specialised in wood, we can easily obtain them and at reasonable prices.

d. the shredder When the flow of waste permits, we may foresee cutting using a shredder[4]. These machines are made of two-axis turning in opposite directions and are equipped with serrated knives. Once caught by the teeth, the products are shredded into strips.

Shredders can cut large objects such as drums, plates or packaging. The size of the particles depends on the width of the knives. They are seldom less than ten millimeters. The rotation speed of the axes is relatively slow (between 50 and 80 revolutions per minute). The installed power to cut the plastic waste must be minimally 7 kW. [5] Throughput (kg/h) can be roughly calculated by multiplying power (kW) by 25:

Failed to parse (syntax error): {\displaystyle Throughput(kg/h)=±25_X_Power(kW)}

The lifespan of the knives is about 1000 hours of work but they can be sharpened repeatedly.

Some machines are equipped with 3 or 4 axes. Moreover, they can be fitted with a perforated grill. The size of the holes determines the maximum size of the particles. In this case, we must ensure that the width of the holes of the knives is greater than the size f the mouth (minimum 12 to 15 mm). The throughput should be reduced. Several passages of material are then recommended, with reduction of the size of the grill openings at each step.

| Charisteristics | Units | |

| Number of axes | (1) 2 (3 or 4) | |

| Width of the knives | mm | >10 |

| Rotation speed of the axes | rpm. | 50 to 80 |

| Power | kW | Min. 7 kW, max. >100 kW |

| Throughput | kg/h. | ±25_X_power |

| Grill opening | mm | >12 |

Table 4.2: General characteristics of shredders

Grinding

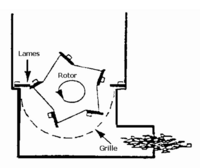

The step of grinding takes the plastic matter from a state of fragment to the state of "flake", that is to say, small pieces properly calibrated and aduquatly sized for introduction into processing machines (extruders, injection presses, ...). The grinding of the plastics is done by shearing of which the principle is shown in the figure below.

In the plastic grinders, the shearing is produced by the cutting tools, the motor-driven knives. There are typically two kinds of grinders that differ by the orientation of the axis bearing the knives.

a. Horizontal axis grinders These grinders are made of a rapidly rotating horizontal cylinder on which knives are mounted. The shearing is done between these movable knives and fixed knives attached to the frame of the grinder. A grid, placed under the knives, determines the size of the grinded fragments. The plastic fragments remain in the grinding zone until their size is smaller than the perforations of the grid.

The rotor is driven by an electric motor via a transmission belt. The speed is usually between 250 and 600 rpm. To shield the engine from having to cope with too large shocks, a flywheel can be placed at the other end of the shaft. According to the machines, the number of mobile knives varies from 2 to 6 (typically 3 or 4). The knives are usually fixed in pairs. For a good performance of grinding, it is important to ensure that the space between the fixed and the mobile knives is as small as possible. In addition, the knives should be regularly sharpened or replaced when worn out. A good quality steel allows to extend their shelf life by around 1000 production hours. A 5 kW motor is the bare minimum for a good grinding of plastics, but an engine greater than 10 kW is recommended. We believe that the hourly throughput of these machines is 10 times the power of the engine:

Failed to parse (syntax error): {\displaystyle Throughput(kg/h)=±10_X_power(kW)}

A regular feeding is necessary. It is unrecommended to keep the grinder running when empty. Considering the installed capacity, particular attention must be paid to the electric supply. An automatic startup may be necessary for large machines. In addition, a well visible emergency stop (with a large red button) is intended to stop the machine quickly in case of trouble.

| Characteristics | Units | Values |

| Number of knives | 2 to 6 | |

| Lifetime of the knives | hours | ± 1000 |

| Rotation speed of the axes | rpm. | 250-600 |

| Power | kW | >5 |

| Throughput | kg/h. | 10_X_power |

| Grill openings | mm | >4 mm |

Table 4.3: Characteristics of grinders with horizontal axis

The grinding area is protected by a metal shroud (see Figure 4.8). The superior part serves the feeding area. Its right angular geometry and flexible component will protect the operator of the return of particles projected by the grinder rotor. We must also ensure that the feed zone is sufficiently high so it does not touch the knives. A hinge should allow to rotate it for gaining access the rotor for cleaning or maintenance of the grinder. Everything must be mounted on a high enough frame to allow recovering the plastic flakes in the trays.

The grinding is a costly preparation step, notably in energy. It is therefore recommended to avoided the smaller cutting as much as possible by carefully choosing the size of the grid perforations. It is generally between 4 and 10 mm according to the size of the particles that can be accepted in the processing machines.

It is sometimes possible that grinding causes the heating of plastics to a degree large enough it to melt. This usually happens when the plastics introduced into the grinder are large, and the perforation of the grid is very small. The cutting time of the plastic in the grinding area is then too long. To remedy this problem, it is necessary to proceed in several steps with grids in which the perforations are successively smaller. An operator has a minimal mechanical experience; enough to control the proper functioning of the grinder. When production is great, a second person may assist him to manage the flow of materials.

Plastics must be grinded per campaign, that is to say, by type and color. After each campaign, a thorough cleaning of the machine must be conducted so as not to contaminate the next campaign. The retrieved plastic flakes are stored in bags unto which are labels are fixed describing the features of the product.

Note: Grinding is a noisy business! The grinder should be installed in a room which is as soundproofed as possible. The operator must protect himself against the noise (headphones, plugs, ...). Moreover, if the center is located in urban areas we must respect a schedule acceptable to the surrounding population.

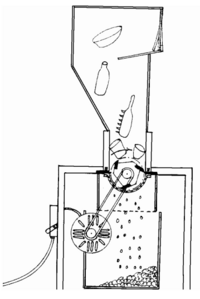

b. Vertical axis grinders The vertical axis grinders are much less efficient than orizontal axis grinders. Yet they are widely available in some countries because they are less expensive and easier to manufacture using traditional methods. Their design is actually simpler (see Figure 4.9). They consist of a cylindrical tub at the bottom of which knives revolve. The bottom of the tub consists of a perforated grid through which the plastic that is grinded enough can pass using gravity. The engine transmission is placed below the grid.

The plastic waste grinder mouth is at the top. In order to protect oneself of the upwards projected particles, the grinder is equipped with a hopper (see horizontal axis grinder) or with a valve system. Knives are used in pairs and are placed diametrically opposed. They must be sharpened regularly to ensure efficient grinding. At equal engine power, the capacity of vertical axis grinders is lower than that of horizontal axis grinders. Access to the grid is more difficult for horizontal axis grinders. It is necessary to disassemble the knives for the changing. Cleaning the grinder is also more difficult.

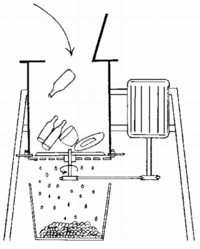

c. Crumber Grinded plastic films are too large and light so as to be introduced in extruders or injection presses. Their feeding is too difficult and the screws are difficult to use in these machines. An additional preparation step is necessary to convert them into more dense and manipulable flakes. This is done with a crumber. The design of this machine is very similar to the vertical axis grinders, except that it does not have a grill in its lower parts. Grinded plastic films remain for some time in the grinding zone. The extensive shearing that they undergo heats them up upto the temperature of softening. The volume of material then decreases rapidly (increased density). At this moment, cold water is introduced into the device, causing a sudden cooling of the material and making the material brittle. The plastic is then recovered in the form of small, irregularly shape granules, but of sufficient density so as to allow later introduction into the processing machines. The required driving force to heat up the plastic is high (minimally 15 kW, triphase). Furthermore, it must undergo major power changes. About five minutes are necessary to soften up the plastic films. Production capacity varies between 40 and 70 kg per hour. The obtained granules can be screened on a grid in order to be calibrated. The too fine particles are reintroduced into the crumber. The introduction of water produces a lot of steam that must be removed using a ventilation system. Changes in temperature and the presence of steam promotes corrosion. An anti-rust treatment must be applied regularly to all of vital parts of the device. Crumbers are very dangerous and relatively expensive machines requiring a cost-benefit analysis before executing the purchase (sufficient amount of plastic films, markets,...). Local manufacturing machines are common in some countries (India, Egypt, Turkey, Mexico, ...).

| Tool | Power | Throughput | Advantages | Disadvantages |

| Knives | 15 to 25 kg per hour and per person | Possibility of "upstream" pre-cutting. Cheap material. | Weak cutting capacity. Exhausting labor. Limited to thin waste. | |

| Fixed scissors | 50 kg per hour per person | Possibility of "upstream" pre-cutting. Lever allows the cutting of thicker sections. Robust hardware. | Limited cutting capacity. Exhaustive labor. | |

| Jigsaws | <5 kW | 40 to 80 kg/h | Motorised system, much more sustainable work. Improved production. | Equipment not designed for cutting plastic (sometimes inappropriate and not very robust). |

| Shredder | >7 kW | > 100 kg/h | Robust system with a high production capacity. Cutting into small fragments, even for rounded objects. | No possibility of "upstream" pre-cutting. Often large investments costs. |

| Horizontal axis grinder | > 5 kW | > 50 kg/h | Robust material, high capacity. Rapid cleaning and maintenance. | Expensive equipment, often imported at great costs. |

| Vertical axis grinder | > 5 kW | > 30 kg/h | Cheaper and easier to make than horizontal axis grinders. | Not very robust. More difficult grid cleaning and changing. Lower capacity. |

| Crumber | >10 kW | 40-70 kg/h | Device specificly used for plastic films. | Costly device that consumes a lot of electricity. |

Table 4.4: Summary of cutting and grinding techniques

Purchasing a grinder: The purchase of a grinder is an important and sensitive issue for which we must take the following considerations into account:

- The first important factor to determine is the required power. As stated previously, it is determined from the throughput of the matter to grind with a minimum of 5 kilowatts. It is always advisable to oversize the grinder, and this for two reasons: to limit heating and to provide the possibility of increasing the production. Grinding is a step prior to the shaping, the grinder should thus be able to comply with the transformation tools.

- The maximum size of the plastic waste entering the grinder is a second important type of data. It determines the minimum size of the feeding zone. If no such device allows the introduction of such pieces of plastic, a pre-cutting step is essential.

- What are the options regarding electricity? This data will be crucial for suppliers or manufacturers of the equipment: frequency, voltage, number of phases ...

- The mode can also be important. For use without stops (regular flow of the same kind of plastic), a powerful grinder is necessary to avoid overheating. For use by campaign (small flows of different kinds of plastic, with cleaning of the grinder in between), a smaller grinder may be sufficient. It will cool during the the cleaning.

Other questions can also be asked:

- What facilities are the cleaning features and the features regarding the grill change ?

- What is the frequency of maintenance ? The lifetime of the knives?

- Does the device comply with the basic safety regulation ?

- What are the conditions for payment and the transportation of the equipment? What warranty is offered on the purchase of the unit? Is there an after-sales service in the country?

- Is the device anchored or or mounted on wheels ?

There are 3 potential markets for the purchase of a grinder:

- Most industrial machines are manufactured in Europe and Northern America. A second-hand market for the machinery is also well established in these countries, but their cost is often high. Most suppliers have well designed websites. For each device, the information is generally included: machine type, brand, power rating, type of possible power supply, width and diameter of the rotor, the number of fixed and mobile knives, the size of the feeding zone, total size of the machine, weight, ... These technical sheets are often accompanied by photographs allowing to see the machine. The price is indicated or e-mailed on request. Before considering the purchase, always inquire about conditions and transportation costs (insurance, import fees, taxes) as well as the warranty. Indeed, a number of additional costs may increase the price of the machine by 50-60%!

- A cheaper alternative than the one described above is the Indian or Chinese market. The recycling of plastic waste is indeed well established in these countries to the point that there are workshops that manufacture specific machines for this activity. The grinders are generally simplified duplicates of imported machinery. The price difference is due to lower manufacturing costs, a less extensive finishing and the dismissal of any safety or noise reduction systems. Sacrifices have also been made regarding robustness regarding the after-sale service. Countries such as Turkey, Mexico and Egypt also have such markets.

- The third possibility is to build one's grinder at a local mechanical workshop. In this case, it better to go to workshops with experience in this field and to follow the assembly to ensure the robustness of the machine. The easiest grinder to make is the vertical axis grinder. Other machines, inspired by traditional cassava grinders can generate small productions, provided that all parts are oversized: the grinding of plastics is indeed more difficult than the grinding of cassava! Knives must be securely mounted unto the rotor.

The advantages of locally manufactured grinders are cost, potential adaptation to specific applications and no problems regarding import. These machines are less efficient (significantly higher electricity costs), less robust (frequent maintenance, low lifetime) and less safe (sometimes dangerous).

When purchasing the grinder, it is better to directly get 1 or 2 knife sets, replacement belts, a set of different grid openings, ...

References

- ↑ There is nevertheless one major exception: the case in which a deposit is made up solely from two types of plastics whose densities are very different. Example: a mixture of PE and PVC. In this case, it is interesting to start off by crushing and then perform the separation by flotation in large tanks of water. PE, which floats in water, can be recovered at the surface while PVC is found at the bottom.

- ↑ "Guide de fabrication d'une pompe à godets" (Bucketpump_construction_manual) is offered by Ingénieurs Assistance International - Ingénieurs Sans Frontières (Belgium). A lighter version is available on-line (www.isf-iai.be). The full version is available on request.

- ↑ Theoretically, a representative sample of the matter must be heated for an hour in an oven at 105°C.

- ↑ In English, the term "shredder" has been generalized for a variety of machines. It is thus best to see the device in person or on an image before making the purchase

- ↑ The power of some models is expressed in horsepower (HP). For information, 1 HP =0.746 kilowatts.