No edit summary |

J.M.Pearce (talk | contribs) mNo edit summary |

||

| Line 10: | Line 10: | ||

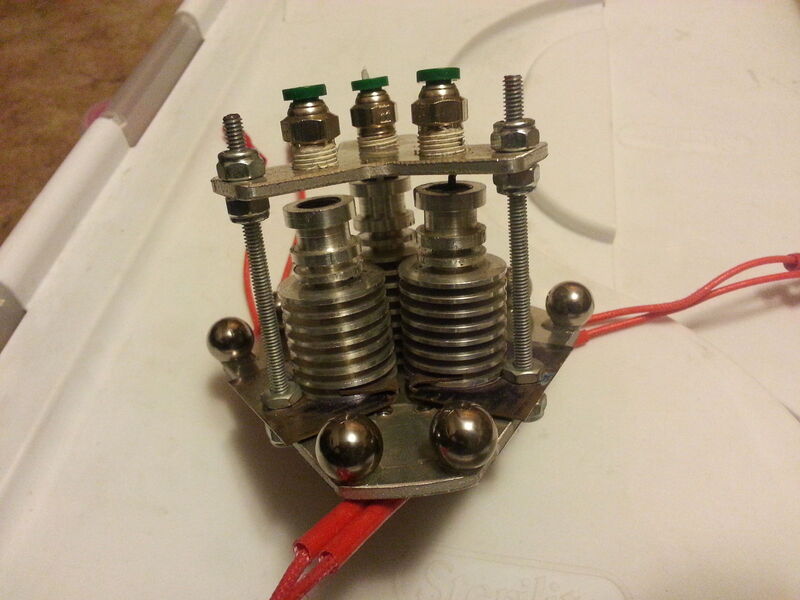

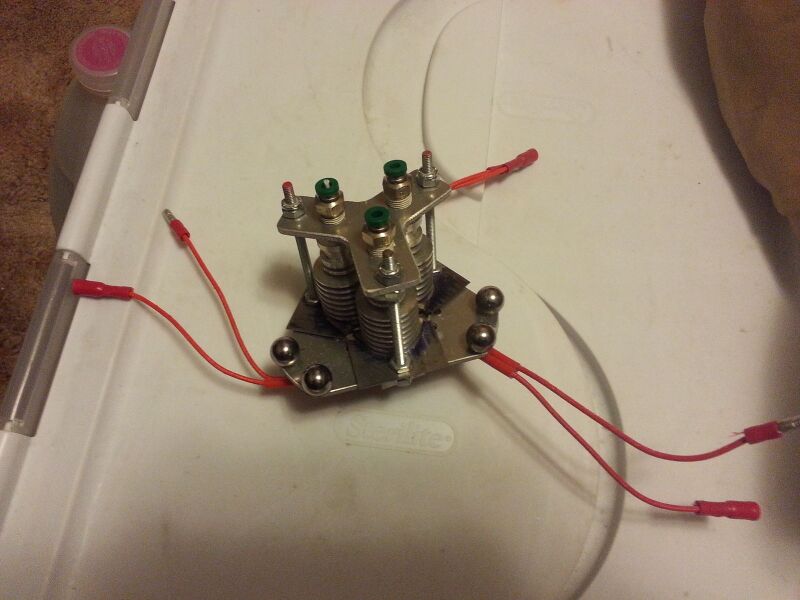

This Effector for a column delta printer allows different hotend nozzle sizes to be used without the effects of localized heating or the unused nozzles colliding with the part due to slight warpage or leveling issues and helps reduce the effect of nozzle drool/ooze. This design new no firmware or other hardware feedback sensors to perform so an easy upgrade to perform for those who don't want to modify their firmware | This Effector for a column delta printer allows different hotend nozzle sizes to be used without the effects of localized heating or the unused nozzles colliding with the part due to slight warpage or leveling issues and helps reduce the effect of nozzle drool/ooze. This design new no firmware or other hardware feedback sensors to perform so an easy upgrade to perform for those who don't want to modify their firmware | ||

Important note the center to center distance of the carriage joints must be the same as the effectors otherwise the effector will not move across the bed in a plane. | Important note the center to center distance of the carriage joints must be the same as the effectors otherwise the effector will not move across the bed in a plane. | ||

Revision as of 11:47, 30 January 2015

Auto-Clearance Adjustable Tripple Hotend Effector

Project developed by User:Nick D.

Template:Statusboxtop Template:Status-design Template:Status-prototype You can help Appropedia by contributing to the next step in this OSAT's status. Template:Boxbottom

Abstract

This Effector for a column delta printer allows different hotend nozzle sizes to be used without the effects of localized heating or the unused nozzles colliding with the part due to slight warpage or leveling issues and helps reduce the effect of nozzle drool/ooze. This design new no firmware or other hardware feedback sensors to perform so an easy upgrade to perform for those who don't want to modify their firmware Important note the center to center distance of the carriage joints must be the same as the effectors otherwise the effector will not move across the bed in a plane.

Bill of Materials

- 6 x 8 x 1/8 inch aluminum plate

- 10/32 Grub screws x 6

- 8/32 x 4 inches x 3

- 1/8 bsp pushfit connectors x3

- E3D version 5 or 6 hotends x3

- 1.5 inch by 6inch by .015 inch shim stock steel

- 12 8/32 locknuts x 12

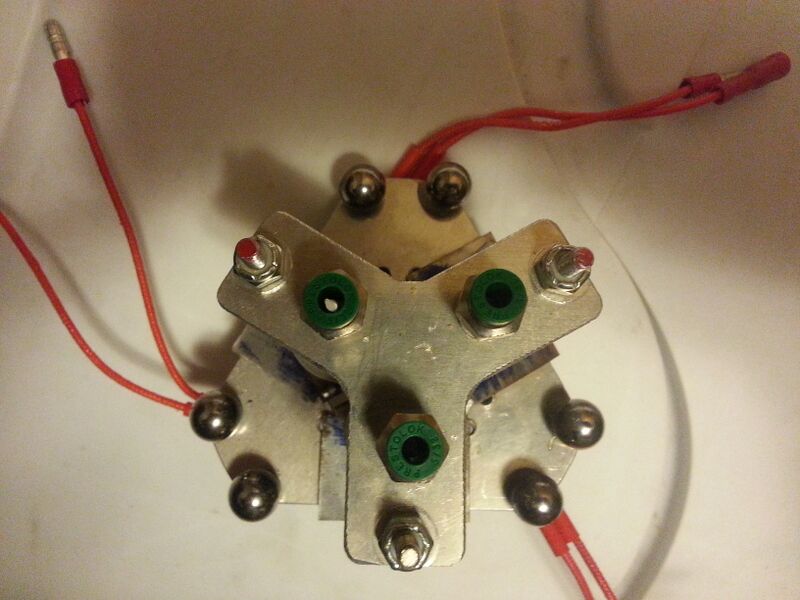

- 1/2 inch ball bearings

- 2 part epoxy

- 1/4 x 4 x .02 inch shim stock steel

The STL file for the parts can be found here: File:Bplate.stl

Tools needed for fabrication of the effector

- Mill

- Drill Press

- Files

- Wrenches

- Allen Wrenches

- Screwdrivers

- Punch Block

- Layout Die

- Sheet Metal Scissor/Shears

Skills and Knowledge Necessary to Make the OSAT

- Machining

- Basic knowledge of Additive Manufacturing

Technical Specifications and Assembly Instructions

- Mill 2 Plates on manual mill with rotary table or cnc mill, or with waterjet cutter.

- Tap holes in base plate

- Cut threaded rod to clear the tops of hotends by 10mm

- Bend metal clips using gage pin and vice or sheet metal bender.

- Using layout die and punch block punch out the springs for each hotend.

- Apply washer to threaded rod followed by spring followed by nut and tighten securely

- Assemble heatsink to hotend while in the spring and apply clips to secure hotends

- Apply top plate so that gap is minizied from top plate to top of hotends while providing clearance for the hotends to move making sure top plate is parallel to base plate and tighten in place.

Common Problems and Solutions

Make sure to use locktite on set screws for each spring to keep them from vibration out during long use. Paint the springs to prevent rust.