Research Interests[edit | edit source]

Open Source Hardware[edit | edit source]

Started with Arduino and Reprap in 2012/2013 and my experience is mainly within 3D printing and C/C++ programming.

Admire the way the GNU project sets technical standards and brings together pieces of free software to form a more generally useful whole. Currently (November 2015) looking for a OSHW-project doing the same thing in practice. Interested in pursuing ideas like "Open Source Ecology" and "Open Source Economy" by creating appropriate technology and clusters of cooperating companies around them.

Since I'm a student of engineering physics, the use of OSHW in research and education is where my focus have been over the last two years.

Artificial intelligence[edit | edit source]

Especially reinforcement learning.

My formal training has been within scientific computing. I want to use that knowledge for writing free and generally useful artificial intelligence algorithms.

Programming and computation in general[edit | edit source]

Especially automatic generation of optimized assembly and the programming language Common Lisp.

I know it's possible to get more quality of life per clock cycle than we currently do. Assembly, Lisp and C are just my current favorite tools for controlling clock cycles.

Current Projects[edit | edit source]

Clerck[edit | edit source]

This is an excerpt of the main article about Clerck.

Clerck is a RepRap hanging from the ceiling, and by far the world's cheapest 3D printer with a massive build volume.

It's currently (November 2015) under heavy development in my kitchen.

Video 1: Here we see the first print ever finished by the hanging RepRap. The video tries to highlight error characteristics to facilitate future improvements.

Video 2: Here we see the first successfull first layer printed by the hanging RepRap.

| Source code: | Github repo | [1] quicklink to firmware |

| Licences: | The repo has GPLv2, the blog uses Gnu Free Documentation Licence, the Vimeo videos are CC-BY licenced | Follows FSF's recommendations |

| Build process: | Blog posts [2], [3], [4], [5], [6], [7], [8], [9], [10], [11], [12], [13], [14], [15], [16] | videos and images, very detailed |

| Development thread: | at forums.reprap.org | some activity, not very detailed |

| Wiki page appropedia.org: | Clerck,_a_RepRap_3D_printer_hanging_from_the_ceiling | updated |

| Wiki page reprap.org: | [17] | outdated |

| All videos: | My Vimeo user |

Previous Projects, CV style[edit | edit source]

2015: Feasibility study of resin-based 3D printing in a CDIO environment[edit | edit source]

More than 10 different low priced resin based 3D printers are hitting the market this autumn (2015). The market is young, and problems are plenty. This report describes a practical procedure to introduce a resin based 3D printer to a CDIO environment (Open Source Hardware lab).

My task was to:

- Write introduction text covering relevant technologies

- Minimize health risks and environmental damage

- Comply with Swedish work environment regulations

- Find practical utilization possibilities within university courses

- Ensure that both beginning and advanced users' preferences are considered

- Design all the needed usage routines

- Suggest a budget

- Suggest a printer

The submitted report is found here: Media:Feasibility_resin_based_printer_Swedish.pdf The following table presents an extremely short summary

| Suggestion | Reason |

|---|---|

| Put the resin printer plans on hold | Available resins are very toxic and non-recyclable |

| 2-year budget: $12,000 | The good enough printers, the resin and required protective equipment is all very expensive |

| Go for Free/Open Source hardware, electronics, resin and firmware | Cheaper, more flexible, more instructive, more safe, producers will go bankrupt |

| Buy Autodesk Ember | Fully Open Source, Autodesk won't go bankrupt, looks nice and friendly |

The project had it's own pilot study in spring 2015. This report was written in English: Media:Resin_report_pilot.pdf

2014: Founded RepRap based company[edit | edit source]

Through the company I have delivered workshops for kids and prints. All work is documented GPL'ed and published (see blog posts [18], [19], [20], also see my Github user). We use open source hardware only.

2014: Sourced and built Reprappro Mendel[edit | edit source]

The printer and the build is described (is Swedish) Here. The build is described in English in a series of blog posts: [21], [22], [23], [24], [25], [26], [27]

2014: IT security analysis for major Norwegian bank[edit | edit source]

Consultant work as a summer intern in Accenture's Norwegian IT security group.

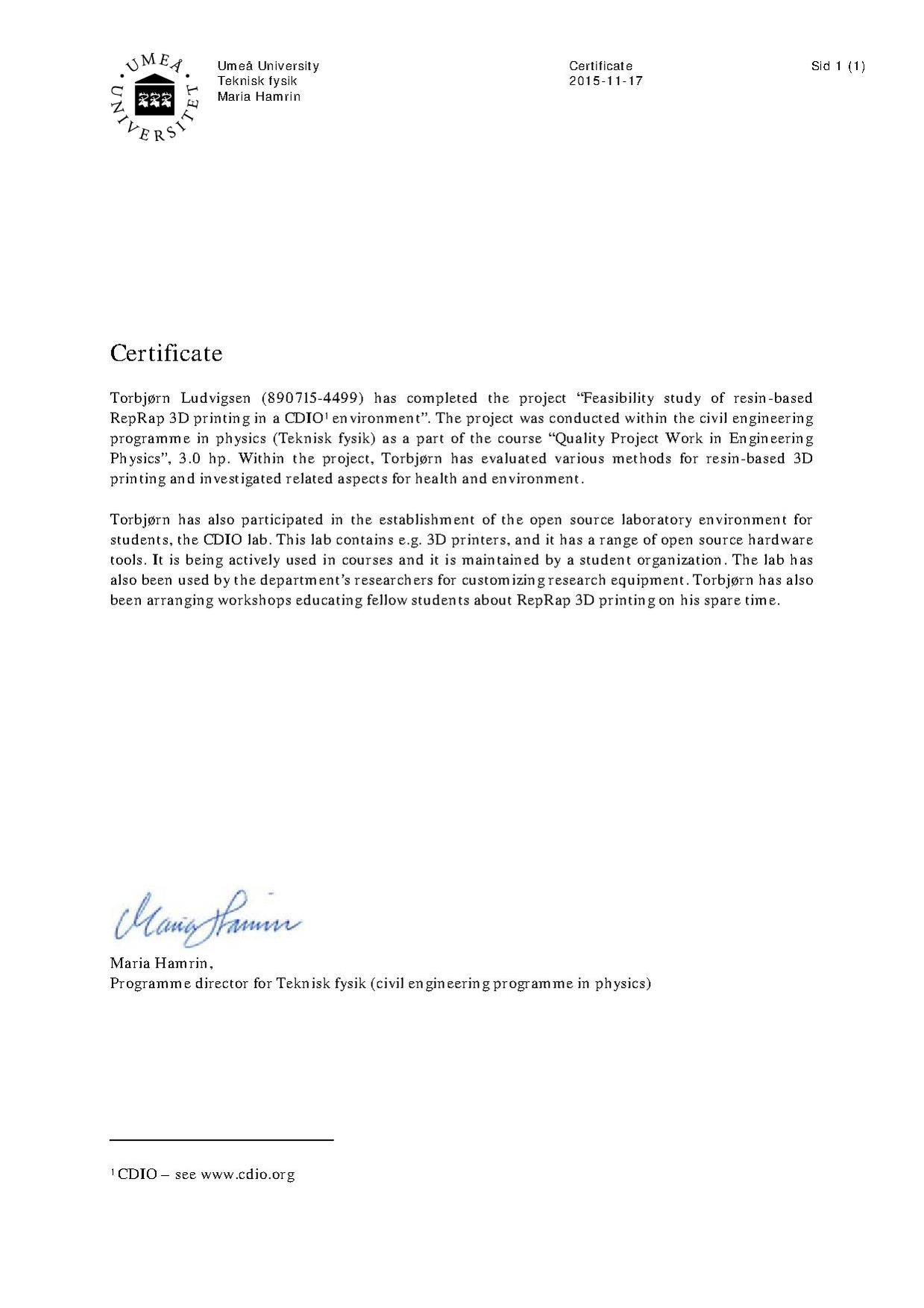

2013 - 2014: Founded Open Source Hardware Lab at the Physics Institution, Umeå University[edit | edit source]

Involved doing feasibility studies, market studies, building several RepRaps, funding, purchasing tools, designing procedures, hosting workshops etc. The lab is now a active CDIO environment with ca 10 machines, exclusively Open Source Hardware and a students association doing all the work.

My work was unpaid and outside course activities, so I got a custom certificate:

2013: Graph database back end for mobile application[edit | edit source]

Team work during Accenture Summer Internship. App got 3000 users, but I was not allowed to open source it.

2013: Building my first RepRap, a Printrbot Plus[edit | edit source]

This led to my initiative to start the 3d-lab at the Physics Institution at Umeå University. The printer is called Sigrid, and is described here.

2013: Arduino-based Inertial Measurement Unit for use as an exercise aid[edit | edit source]

The unit used an Arduino mini board, an MPU-6050 (accelerometer + gyro) and a Bluetooth antennae together with code from the FreeIMU project.  . Orderer was KriMag Techonology AB

. Orderer was KriMag Techonology AB

In Media[edit | edit source]

- Article (Swedish) Describes official initiation of the 3D lab that resulted from previous project Founded Open Source Hardware Lab ...

- Article (Norwegian) Describes previous projects Sourced and built Reprappro Mendel and Founded RepRap based company.