[[category:242-2017 People]]

Pierson Gill[edit | edit source]

Pierson (The Rock) Gill was born February 27th, 1996 in a small town outside Pittsburgh, PA known as Imperial and later moved to Exton, PA which is outside Philadelphia, PA. He is a full time student at Principia College where he is a business and education major. Pierson is on the Principia College Men's Soccer team, member of the Prinicipa College Waterski Club and a former member of the Principia College Track and Field Team.

3D Printing[edit | edit source]

Pierson does not ahve very much experience 3D printing, but is very interested in the subject. He recently built his own 3D printer for his 3D printing class at school. Pierson and a few other friends built their printers in the first weekend and have been having fun exploring the world of 3D printing.

Education[edit | edit source]

Pierson graduated from Downingtown High School East Campus in his hometown in 2014. He is currently a Junior at Principia college where is he soon to become a business and education major. He will graduate in the spring of 2018.

Open Source[edit | edit source]

I think that the open source movement is remarkable. To me it is the ability for a community to get together and share ideas, inventions and other things. This also includes the improving other's people previous works to make them better. To me the open source community is a way for growth and trust that will lead to a high rate in technological advancement. I am attracted to the idea of constant improvement. I am also attracted to how it is easy to find new fun, new things to print and how willing people are to share what they have created. I am somewhat worried about the people I cannot meet. I think it is very easy for people hiding behind screens to ruin people's works, but I am glad that is is not very relevant among the open source community. I really enjoyed building my Jellybox printer and becoming part of the open source movement. I had a very fun time putting it all together and felt a great sense of pride when it was put together and when it worked. I am not sure where i will go with it in the future, but i hope to get to the point were I can build my own parts and create things that other people may want to use.

My Stuff[edit | edit source]

| Picture | Description | Something else |

|---|---|---|

|

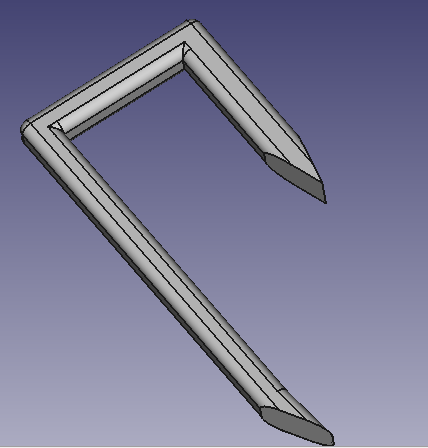

This is the hot-end i used on my JellyBox Printer | Something else |

Variable Testing Using PASCO Coupons[edit | edit source]

After testing, I found both of these hypotheses to be correct. The higher-heat prints survived more newtons of force, and elongated less, than the lower-heat counterparts. The horizontal prints were also stronger than their vertically-printed counterparts. On the left is an example of my best stress-test graph, with a horizontal coupon printed at 220 degrees Celcius. This print withstood 245 Newtons of tension trying to pull it apart, while only elongating 0.13 mm.

So, in summary, I will print future prints at a higher temperature in order to bond the plastic material better. Our printers offer a heat testing feature which I have yet to explore, and this step seems like a logical way to pursue greater understanding of how print temperatures affect quality.

Minimash Project[edit | edit source]

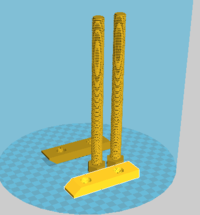

For our next class project we had to take a celtic design and put it on an object. The object that i had to put it on was a coaster. So in the end, i had to use design software to take a celtic design and place it on a round cylinder which was my coaster. In the end i was very happy with how it turned out! Picture is coming soon! my teacher currently has the print.

OSH Science Project[edit | edit source]

For my interview with a teacher in regards to picking a subject matter to design and print, I talked to Jonathan Langton. Unfortunately after talking he did not have an ideas for me. So, I decided to design and print a 3d long board wheel that had holes for bearings which would allow for it to spin and work if it is placed on long board trucks. This is something i am excited about because I like to make my own long boards. It does qualify as being scientific because this wheel does not have to be used only for a longboard, but other devises and other tests can be used using this wheel.

I used free cad to design the wheel, and then I used Net fab to design an outer shell for the wheel so it could be sliced and printed successfully!

The Final piece came out great, it is ready for bearings and ready to go on a longboard. The wheel is very strong, but im thinking it might be too brittle for hitting small rocks. I would like to be able to put some sort of rubber heat shrink on the outside to add grip to the wheel and padding from rocks. In the end I can make the wheel bigger or smaller using cura to fit different sized bearings, and even different objects that I would need a wheel to be on. It would be super useful as a spare wheel to any part to provide a quick, affordable fix. As far as the price for longboard wheel, a set of four costs 60-90 dollar depending on the quality, so by printing my own wheels i am saving a lot of money. Depending on other devises with wheels, I could be saving a priceless amount of money if they dont manufacture spare wheels. I had fun designing and printing my own print and having it physically in my hand is awesome!

Here is my STL for my print!Media:Example.ogg

OSAT[edit | edit source]

TImproved tent stakes[edit | edit source]

Project developed by Pierson Gill Status Meter: Prototype

Abstract[edit | edit source]

- Paragraph description of the OSAT - why is it Appropriate? What need does it fulfil? Are there case studies you have found of a technology being used successfully?

- Picture of completed print using

Bill of Materials[edit | edit source]

- Provide a full BOM -- Materials needed for fabrication of device and alternative materials if they are not available, prices/sources of non-printable parts

- Link to all source files from open source CAD: File:Tent stake.FCStd

- Upload and link to all STLs

Tools needed[edit | edit source]

- Jellybox or similar RepRap 3-D printer

Skills and knowledge needed[edit | edit source]

- If you used special skill – link to relevant wikipedia or wikiversity articles/courses

Technical Specifications and Assembly Instructions[edit | edit source]

- Provide directions for print/assembly - be detailed enough in your “how to” to ensure that someone could construct the device from your description. Consider the elegance of IKEA like instructions.

- Include print time estimate

- Include assembly time estimate

- Including drawings or pictures of the device at stage of assembly at minimum. (Upload)

- Consider video if appropriate

Common Problems and Solutions[edit | edit source]

- Include common mistakes/problems to avoid in building your OSAT and how to overcome them

Cost savings[edit | edit source]

- If your solution is not a low cost one then it is not really appropriate.

- Estimate your costs

- Find a commercial equivalent

- Calculate $ savings and % savings

References[edit | edit source]

- The sources of information (e.g. engineering handbooks, journal articles, government documents, webpages, books, magazine articles etc.). References should use the <ref> </ref> and <references /> tags and can be in any format but should include all the information necessary for someone else to find the same information you did. For example: [1]

Videos[edit | edit source]

Coming Soon!!

- ↑ web page: Department of Energy (DOE) Landscaping and Energy Efficiency, DOE/GO-10095 (1995) Available: http://web.archive.org/web/20021201231338/http://www.eren.doe.gov:80/erec/factsheets/landscape.html