Current Career Objective[edit | edit source]

I am striving to obtain a design or research & development position in the biomedical and/or materials engineering field, where I can utilize my industrial and commercial work experience, as well as my research experience to assist the company in developing materials and products that are cutting edge. To achieve this, I have been dedicated to my research with Michigan Technological University, and continue to develop my skills through "on the job" experience within Industry.

Renegade Research[edit | edit source]

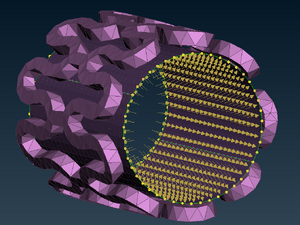

Development of a Real Time 3D Simulation of a Balloon Catheter Deployed Stent[edit | edit source]

I started off my research career as a little kid who would test the durability of many objects, my parents thought that I was destructive but in all reality I was conducting my own experiments, just not documenting them properly. Now my research has matured some... I currently am conducting my own research at Michigan Technological University with funding that I obtained from the Michigan Space Grant Consortium. My research involves developing a real time 3D simulation of a Balloon Catheter Stent being deployed in the Ascending Aorta of a Rat. The goal of this simulation is to provide a standard platform for which different materials can be tested and compared in an virtual environment that very closely mimics the biological environment that is present within a cardiovascular system. By developing a platform simulation, different materials can be added with great ease, and without any manipulation of the base simulation. This way the viability of a new stenting material can be tested before the material is even developed. A theoretical material can be created based on the users desired mechanical, thermal, acoustic, and chemical properties. This theoretical material can then be inserted into the simulation, and its performance can be measured. All of this can be done before the material is actually developed, greatly reducing the amount of trial and error that goes along with developing a new material.

The simulation uses Finite Element Modeling principles and techniques that have been deployed in the aerospace and automotive industry for many years. My goal is to use the capabilities of Finite Element Analysis (FEA) software that has been used in these industries and apply the same principles to the medical industry. With the cost of American Healthcare skyrocketing, FEA could be a fundamental tool in reducing the cost of medical equipment and devices by...

- Determining the viability of a material in a system before the material is purchased or developed.

- Determining the probability of medical device failure without expensive in-vivo and in-vitro testing.

- Reducing the amount of time it takes to go from an idea to a product.

- Having the ability to change experimental parameters virtually.

- Developing medical devices and instruments that can be personalized to the individual that it is intended for.

- Aiding in the development of materials that are more cost effective and economical to produce.

- Having the ability to test long term systems that take years to test in-vivo or in-vitro in a matter of days.

In order to construct this simulation and increase my knowledge of the field, I have developed skills with the following Computer Aided Engineering (CAE) and FEA software...

- CAE Software

- FEA Software

- Scripting Software

Surface Innovations Research Team[edit | edit source]

Undergraduate Research Assistant

Michigan Technological University

January 2013 – Present (9 months)Materials Science Department

Surface Innovations and Cardiovascular Team

Research Assistant for Dr. Jaroslaw Drelich: (906) 487-2932

- Evaluation and testing of first-generation, experimental metallic biomaterials.

- Improving the mechanical performance of zinc-based alloys through deformation processing.

- Working for the Surface Innovations research group under Professor Jarosloaw Drelich.

- Analyzing size and distribution of nanoparticles from images taken by a Scanning Electron Microscope.

- Created and constructed a computer model simulating the deployment, expansion, and retention of a balloon catheter deployed stent.

- Used Computer Aided Engineering and Finite Element Analysis methods to assess metallic biomaterials.

- Created benchmarks for computer modeling of stent design and material combinations.

Internship & Co-Op Experience[edit | edit source]

BASF Corporation Internship[edit | edit source]

Engineering Plastics, Advanced Development Group (ADG), Student Intern

May 2013 – Present (5 months)Wyandotte Michigan

Summer Internship with the Engineering Plastics Advanced Development Group.

- Construction of CAD models from design sketches, physical parts, and 3D scans using Solidworks, Unigraphics, and Solid Thinking.

- Pre-Process CAD models for Finite Element Analysis using HyperWorks, ANSA, and Abaqus.

- Completing Static (Implicit), Dynamic (Explicit), and NVH (Noise, Vibration, and Harshness) analysis of engineering components using Solidworks, Abaqus, Nastran, Radioss, and LS-DYNA.

- Topology Optimization of engineering components using Tosca Structure, Optistruct, and Inspire.

- Completed project assignments designed to develop engineering applications utilizing Thermoplastic materials.

- Assess the potential for use of plastics for weight reduction in industry parts and applications that currently use metals such as steel, aluminum, and Magnesium.

- Develop solar panel mounting systems that utilize cutting edge material and minimize the 'Cost per Watt" for product development and instillation.

- Create engineering reports for customers outlining material cost, tooling cost, design optimization, and CAE/FEA analysis'.

BASF Corporation Cooperative Education Program[edit | edit source]

CAE Engineering Plastics Co-op

May 2012 – December 2012 (8 months)Wyandotte MI

Summer - Fall Co-Op with CAE FEA Engineering Plastics Department

- Assist CAE engineers in performing Finite Element and Mold Filling Analysis by building computer models (using shell and solid elements) of plastic components.

- Perform computer aided design (CAD) work using such programs as Unigraphics NX, Solidworks, building geometric 3D models of conceptual designs sketched by design engineers.

- Perform project assignments, with the help of application development and CAE engineers to design and develop applications utilizing engineering plastic materials.

- Use of computer software to design, and evaluate potential use of different plastics in many industry parts and applications.

Michigan Tech Work Study Program[edit | edit source]

Student Supervisor and Labratory Assistant

Michigan Technological University

September 2007 – January 2011 (3 years 5 months)Houghton MI

- Supervised and trained in new work study students.

- Managed students work and class schedules as well as research materials placed on site by professors.

- Assisted students, local citizens, and professors in locating research materials.

- Completed M.S.D.S. and other related lab safety training.

- Received training in laboratory equipment operation and maintenance including: autoclaves, incubators, centrifuges, and biological safety cabinets.

- Help maintain and organize research laboratories and classrooms.

- Categorized chemicals, compounds, and research equipment in storage rooms.

Organizations[edit | edit source]

Sigma Pi Fraternity International, Zeta Epsilon Chapter

President, Vice President, House Manager

September 2008 – Present

- Ensured board members, committees and brothers discharged their various duties and met their obligations on time.

- Organized weekly chapter meeting, organized chapter publications, and created weekly meeting agendas

- Organized weekly executive board meetings, and created weekly agendas for executive board members.

- Provided fraternal and professional mentor-ship to numerous students, alumni, and volunteers.

- Organized house fundraising and community service activities, and maintained positive public relations with the Community, University, Greeks organizations, and Alumni.

- Attended annual Sigma Pi Midyear Leadership Conferences and Convocations

Other Organizations[edit | edit source]

- Michigan Tech Materials United

- Michigan Tech Biomedical Engineering Society

- United States Coast Guard Reserves

Contact details[edit | edit source]

| Phone Numbers | Email Addresses | Mailing Address |

|---|---|---|

| HOME = 906-231-0146 | ACADEMIC = mmwarhus@mtu.edu | 1206 College Ave |

| CELL = 906-231-0146 | PERSONAL = mmwarhus@gmail.com | Houghton, MI 49931 |