This simple motor was constructed from a 10.5cm section of bamboo, a set of battery terminals, a magnet, roughly one meter of wrapping wire, and about 10 cm of standard shielded wire. It was inspired by a quick suggestion by my teacher Lonny Grafman. In the midst of our Appropriate Technology instruction for the Parras 2008 program, it seemed only acceptable to build it out of already available materials.

It is a project that can be done by almost anyone with a little patience and some extra time. It is a valuable for teaching some of the basic principles of electricity as well as the basics of a direct current electric motor.

Plans[edit | edit source]

The design for this type of electric motor was something that I remembered from my childhood tinkering. The only thing that was really different this time is that I was limiting my supplies.

I had the use of bamboo in mind from seeing it around Parras de la Fuente, MXW.

I wasn't exactly sure how I wanted to implement it, but after a quick sketch it was clear to me.

This image roughly depicts the sketch I made just before building. The idea was to use one short section of bamboo and split it down the center. On the inside of the bamboo, the wiring and possibly a battery could be hidden.

Materials[edit | edit source]

-

Bamboo

-

Wrapping Wire

-

Magnet

-

Battery Terminals

-

Shielded Wire

-

Power Source

-

Soldering Iron

-

Solder

-

Flux

Construction[edit | edit source]

Overall construction took about an hour, though through repeating the project it could take far less time. Parts are listed in the order that they were constructed.

Armature[edit | edit source]

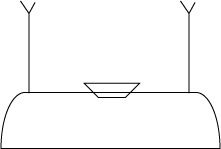

The Armature is the part of the motor which does the spinning in this situation. The armature was made by wrapping a length of the wrapping wire around a section of bamboo several times. The coil of wire was then bound in two places by small pieces of wire to keep it from coming apart. Extra lengths of wire were added to the axis for strength.

Then a soldering iron was used to melt off part of the plastic coating on the wire. At the same time solder was added to hold the wires together and create a connection between the different insulated wires.

It is important that the armature does not have contact with the posts 100% of the time. The motor functions by pulsing a magnetic field. If there is a connection all of the time then the motor will either not turn or will not be as efficient.

Base[edit | edit source]

The base of the motor is constructed of bamboo. It was cut so that the nodes were not included in the section that was used for the motor.

The bamboo was cut and split down the center using a pocket knife. Then a hole was cut in the center of the section for the magnet. The armature was then placed over the magnet to properly position the holes for the posts. The holes were punched in the bamboo using a pocket knife.

Small notches were made in the sides of the base as a place for the lead wires to be fitted.

Posts[edit | edit source]

The posts could be constructed of a number of conductive materials, though battery terminals seem to work exceptionally well.

The plastic insulation was stripped off of the terminals and were pushed through the holes in the bamboo. The posts were reinforced from the bottom side of the bamboo using lengths of wire and excessive amounts of solder. The leads from the posts were then fitted into the notches in the base for extra strength.