Gambar 1: Akar kunyit segar. Foto: Tindakan Praktis/Neil Noble

Gambar 1: Akar kunyit segar. Foto: Tindakan Praktis/Neil NobleHalaman ini menjelaskan detail pengolahan kunyit.

Isi

Perkenalan

Kunyit (Curcuma domestica) merupakan tanaman tahunan tegak yang ditanam sebagai tanaman tahunan untuk diambil rimpangnya. Ia termasuk dalam famili yang sama dengan jahe (Zingiberaceae) dan tumbuh di iklim tropis yang sama panas dan lembab. Rimpangnya berwarna kuning cerah pekat dan ukuran serta bentuknya mirip dengan rimpang jahe. Tanaman ini berasal dari anak benua India dan saat ini India adalah produsen dan konsumen kunyit terkemuka di dunia. Itu juga diproduksi di Cina, Taiwan, Bangladesh, Indonesia, Sri Lanka, Australia, Afrika, Peru dan Hindia Barat. Kunyit memainkan peran penting dalam budaya India - merupakan bahan penting dalam kari, digunakan dalam festival keagamaan, sebagai kosmetik, pewarna kain, dan dalam banyak pengobatan kesehatan tradisional. Bumbu ini kadang-kadang disebut sebagai 'kunyit India'.

Produksi kunyit

Tanaman Kunyit diperbanyak dengan cara menanam potongan rimpang musim sebelumnya yang tumbuh membentuk tanaman dengan tinggi sekitar 0,9 meter. Tanaman ini memiliki daun bertangkai panjang dan bunga berwarna kuning pucat serta membutuhkan tanah yang liat. Tanaman ini tumbuh pada berbagai kondisi iklim, namun memerlukan curah hujan antara 1000 dan 2000mm per tahun. Dapat tumbuh di lokasi yang ketinggiannya mencapai 1220m di atas permukaan laut.

Pemanenan

Kunyit dipanen saat tanaman berumur antara 7 hingga 10 bulan, saat batang dan daun mulai mengering dan mati kembali. Seluruh tanaman dikeluarkan dari tanah, berhati-hatilah agar rimpang tidak terpotong atau memar.

Berkeringat

Daunnya dikeluarkan dari tanaman dan akarnya dicuci dengan hati-hati untuk menghilangkan tanah. Sisik daun dan akar yang panjang dipotong. Cabang samping (lateral) (yang dikenal sebagai jari) rimpang dikeluarkan dari umbi pusat utama (dikenal sebagai induk). Ibu dan jari-jarinya ditumpuk terpisah, ditutup dengan dedaunan dan dibiarkan berkeringat selama satu hari. 'Induk' adalah bahan pilihan untuk ditanam pada tahun berikutnya.

Pengobatan

Sebelum dikeringkan, rimpang kunyit harus diawetkan terlebih dahulu. Caranya adalah dengan merebus akarnya untuk melunakkannya dan menghilangkan bau mentahnya. Setelah proses pengawetan, pati menjadi gelatin, sehingga mengurangi waktu pengeringan yang dibutuhkan, dan warnanya didistribusikan secara merata ke seluruh rimpang. Spesifikasi pengawetan kunyit berbeda-beda di setiap tempat. Institut Penelitian Rempah-rempah India dan Pusat Penelitian Pertanian merekomendasikan merebus dalam air biasa selama 45 menit hingga muncul buih di permukaan dan keluar aroma khas kunyit. Dengan cara ini, warna rimpang akan memburuk jika rimpang direbus terlalu lama. Namun jika tidak direbus cukup lama, rimpangnya akan rapuh. Tahap optimal dicapai ketika rimpang masih lunak saat disentuh atau dapat tertusuk kayu tumpul.

Peneliti lain merekomendasikan merebus rimpang dalam larutan basa, terbuat dari 0,05% hingga 1,0% natrium karbonat atau kapur (kalsium karbonat). Air alkali diduga dapat meningkatkan warna akhir kunyit kering. Karena jari dan umbi memiliki ukuran dan ketebalan yang berbeda satu sama lain, penting untuk mengawetkannya dalam kelompok yang berbeda. Waktu pengawetan tergantung pada umur, varietas dan ukuran serta ketebalan rimpang dan bervariasi dari satu hingga empat atau enam jam. Hal ini juga dipengaruhi oleh ukuran batch – batch yang lebih kecil umumnya menghasilkan kunyit kering dengan kualitas lebih tinggi karena proses pengawetan lebih mudah dikendalikan dan dipantau. Disarankan menggunakan wadah berlubang dengan kapasitas 50-75kg. Wadah berlubang direndam dalam air mendidih selama waktu memasak yang diperlukan. Cara ini memungkinkan air rebusan digunakan untuk lebih dari satu batch kunyit. Waktu terbaik untuk pengawetan adalah dua hingga tiga hari setelah panen. Jika ditunda setelah ini maka rimpangnya mungkin mulai rusak. Manfaat pengobatan kunyit antara lain sebagai berikut:

- Pengurangan waktu pengeringan

- Penyebaran warna lebih merata ke seluruh rimpang

- Produk lebih menarik (tidak kusut) dan lebih mudah dipoles

- Sterilisasi rimpang sebelum dikeringkan.

Pengeringan

Rimpang diiris sebelum dikeringkan untuk mengurangi waktu pengeringan dan meningkatkan kualitas produk akhir (lebih mudah untuk mencapai kadar air akhir yang lebih rendah pada potongan kecil rimpang tanpa merusak penampilan produk). Rimpang secara tradisional diiris dengan tangan, tetapi tersedia mesin kecil untuk melakukan proses ini. Gambar 2 adalah mesin pengiris kunyit sederhana yang dirancang di Bolivia. Ini adalah struktur sederhana yang berisi sistem transmisi dan dua bilah melingkar baja tahan karat. Mesin ini mudah dibuat dan dirawat serta dapat memotong hingga 120kg kunyit per jam.

Gambar 2: Mesin pengiris sederhana yang digunakan di Bolivia( http://www.fao.org/inpho/content/compend/text/ch29/ch29 02.htm)

Gambar 2: Mesin pengiris sederhana yang digunakan di Bolivia( http://www.fao.org/inpho/content/compend/text/ch29/ch29 02.htm)Jari atau umbi yang sudah matang dikeringkan hingga memiliki kadar air akhir 5-10%. Pengolah kunyit berpengalaman. akan mengetahui kapan rimpang sudah cukup kering karena jari akan menjentikkan dengan bersih dengan suara logam. Secara tradisional potongan rimpang diletakkan di atas lantai beton yang bersih dan dijemur. Cara ini bisa memakan waktu 10 hingga 15 hari, tergantung iklim dan ukuran rimpang. Potongan rimpang sebaiknya tidak ditaruh di bawah sinar matahari langsung karena akan menyebabkan warnanya memudar. Menggunakan pengering mekanis akan menghasilkan warna yang lebih baik dan kualitas produk yang lebih tinggi.

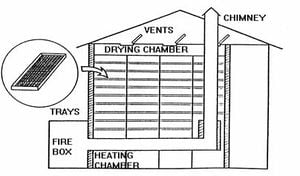

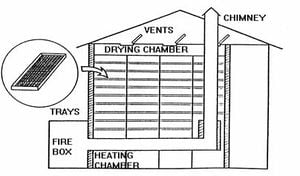

Ada beberapa jenis pengering mekanis yang cocok untuk mengeringkan kunyit. Ini termasuk pengering baki, terowongan udara aliran silang, pengering tenaga surya, dan pengering kabinet. Suhu pengeringan optimal adalah 60°C – suhu yang lebih tinggi dari ini akan menghasilkan produk berwarna lebih gelap. Lihat ( Ringkasan Teknis Tindakan Praktis ) mengenai pengeringan untuk informasi umum lebih lanjut mengenai pengering.

Gambar 3: Pengering baki pada umumnya

Gambar 3: Pengering baki pada umumnya

Gambar 4: Pengering tenaga surya yang dikembangkan di Bolivia http://www.fao.org/inpho/content/compend/text/ch29/ch29 02.htm

Gambar 4: Pengering tenaga surya yang dikembangkan di Bolivia http://www.fao.org/inpho/content/compend/text/ch29/ch29 02.htmPemolesan

Setelah kering, rimpang dipoles untuk menghilangkan permukaan kasarnya. Hal ini dapat dilakukan dengan tangan atau dengan mengocok rimpang dalam karung goni yang berisi batu. Drum pemoles digunakan di banyak tempat – ini adalah drum yang sangat sederhana dan digerakkan dengan tenaga yang memiliki lapisan jaring logam yang bersifat abrasif. Di beberapa tempat, rimpang ditaburi dengan larutan kunyit bubuk dalam air pada saat pemolesan akhir, untuk memberi warna yang bagus pada rimpang.

Penilaian

Spesifikasi mutu kunyit diberlakukan oleh negara pengimpor. Mereka mengacu pada kebersihan produk dan bukan pada kualitas makanan. Rimpang massal dikelompokkan menjadi jari, umbi, dan dibelah. Standar kunyit di India mengikuti Spesifikasi Agmark (Direktorat Pemasaran Pertanian) untuk memastikan kualitas dan kemurnian produk.

| Nilai | Fleksibilitas | Potongan pecah, jari <15mm- Tidak lebih dari (% berat) | Benda asing-Tidak lebih dari (% berat) | Cacat- Tidak lebih dari (% berat) | Persentase umbi menurut beratnya maks |

|---|---|---|---|---|---|

| Jari Alleppey (a) | |||||

| Bagus | Sulit untuk disentuh | 5 | 1 | 3 | 4 |

| Adil | Keras | 7 | 1.5 | 5 | 5 |

| Jari selain Alleppey | |||||

| Spesial | Sulit untuk disentuh, dentingan logam saat putus | 2 | 1 | 0,5 | 2 |

| Bagus | Sama | 3 | 1.5 | 1 | 3 |

| Adil | Keras | 5 | 2 | 1.5 | 5 |

| Jari Rajapore (b) | |||||

| Spesial | Sulit untuk disentuh, dentingan metalik saat putus | 3 | 1 | 3 | 2 |

| Bagus | Sama | 5 | 1.5 | 5 | 3 |

| Adil | Keras | 7 | 2 | 7 | 5 |

| Tidak Ditentukan | |||||

| - | 4 | ||||

| - | |||||

| Umbi (c) | |||||

| Spesial | - | - | 1 | 1 | |

| Bagus | |||||

| - | 1.5 | 3 | |||

| Adil | |||||

| 2 | 5 |

Tabel 1: Standar Agmark untuk rimpang kunyit (www.turmeric.8m.com/standards.html)

a Jari-jari berasal dari rimpang sekunder Curcuma longa L.; harus diatur dengan baik dan berbutir rapat; bebas dari umbi; harus benar-benar kering dan bebas dari kerusakan kumbang dan serangan jamur serta tidak diwarnai secara buatan dengan bahan kimia. B. Sama seperti (a); mempunyai ciri-ciri varietas; Pencampuran varietas kunyit yang diperbolehkan maksimal 2%, 5%, 10% dan 10% untuk keempat grade masing-masing. C. Umbi merupakan rimpang utama Curcuma longaL.; harus berkembang dengan baik, halus dan bebas dari akar-akar kecil; mempunyai ciri-ciri yang beragam; kering sempurna dan bebas dari kerusakan akibat kumbang dan serangan jamur; tidak diwarnai secara artifisial dengan bahan kimia.

Varietas kunyit

| Alleppey | Berasal dari Kerala. Memiliki warna kuning tua dengan kandungan pigmen yang tinggi (6,5% kurkumin). Tipe ini populer di Amerika. |

|---|---|

| Madras | Berasal dari Tamil Nadu. Merupakan warna mustard dengan kandungan pigmen lebih rendah (kurkumin 3,5%). Jenis ini populer di Inggris. |

| India Barat | Berasal dari Karibia. Warnanya coklat kekuningan kusam. |

Tabel 2: Varietas kunyit.

Menggiling

Penggilingan dapat menjadi salah satu metode untuk memberikan nilai tambah pada suatu produk. Namun, secara umum rempah-rempah tidak disarankan untuk digiling karena lebih rentan terhadap pembusukan. Senyawa rasa dan aromanya tidak stabil dan akan cepat hilang dari produk yang digiling. Umur simpan bumbu halus jauh lebih singkat dibandingkan bumbu utuh. Sangat sulit bagi konsumen untuk menilai kualitas suatu bumbu halus. Oknum pengolah juga sangat mudah mencemari bumbu halus dengan menambahkan bahan lain. Oleh karena itu sebagian besar konsumen, mulai dari pedagang grosir hingga konsumen perorangan, lebih memilih membeli rempah utuh.

Kunyit merupakan salah satu dari sedikit bumbu yang biasa dibeli Gambar 5: Kunyit giling. dalam bentuk dasar. Potongan rimpang utuh dapat Foto: Tindakan Praktis / Neil Noble diekspor dan kemudian digiling di negara tujuan. Alternatifnya, rimpang kering dapat digiling di tempat asalnya.

Penggilingan adalah proses yang sangat sederhana yang melibatkan pemotongan dan penghancuran rimpang menjadi partikel-partikel kecil, kemudian menyaringnya melalui serangkaian saringan dengan ukuran mata jaring yang berbeda, untuk mendapatkan bubuk halus. Ada berbagai pabrik penggilingan yang tersedia, baik manual maupun bertenaga, dengan kapasitas berbeda dan cara kerja berbeda. Cara tradisional untuk menggiling adalah di antara dua batu. Keuntungan cara ini adalah kunyit tidak menjadi terlalu panas saat proses penggilingan. Pada beberapa pabrik mekanis, seperti pabrik palu, panas dihasilkan selama proses penggilingan, yang dapat menyebabkan hilangnya beberapa senyawa rasa dan aroma yang mudah menguap. Untuk kunyit bubuk berkualitas lebih tinggi, suhu penggilingan harus dijaga serendah mungkin.

Setelah digiling, bubuk diayak melalui saringan mesh yang berbeda sampai diperoleh bubuk halus yang seragam.

| Nilai | Kelembapan (%b/b) maks | Total abu (%b/b) maks | Abu tidak larut asam (%b/b) maks | Timbal (ppm) maks | Pati (%b/b) maks | Tes kromat |

|---|---|---|---|---|---|---|

| Bubuk kunyit (a) | ||||||

| Standar | 10 | 7 | 1.5 | 2.5 | 60 | Negatif |

| Bubuk yang digiling kasar (b) | ||||||

| Standar | 10 | 9 | 1.5 | 2.5 | 60 | Negatif |

Tabel 3: Standar Agmark untuk bubuk kunyit (www.turmeric.8m.com/standards.html) a. Giling hingga lolos saringan 300 mikron b. Giling hingga melewati saringan 500 mikron

Kemasan

Rimpang kering dan potongan rimpang dikemas dalam karung goni, kotak kayu atau kotak karton bergelombang berjajar untuk pengiriman.

Kunyit bubuk harus dikemas dalam kemasan polietilen kedap udara dan tahan lembab. Kemasan harus disegel dan diberi label yang menarik. Label harus memuat semua informasi produk dan hukum yang relevan – nama produk, nama merek (jika sesuai), rincian produsen (nama dan alamat), tanggal pembuatan, tanggal kedaluwarsa, berat isi, bahan tambahan ( jika relevan) ditambah informasi lain yang mungkin diperlukan oleh negara asal dan negara pengimpor (barcode, kode produsen, dan kode pengemas adalah informasi tambahan yang diperlukan di beberapa negara untuk membantu melacak produk hingga ke asalnya). Lihat Ringkasan Teknis Tindakan Praktis mengenai pelabelan untuk informasi lebih lanjut mengenai persyaratan pelabelan.

Penyimpanan

Rimpang curah disimpan di lingkungan sejuk dan kering, jauh dari sinar matahari langsung. Warna cerah kunyit bubuk akan memudar jika dibiarkan dalam waktu lama. Oleh karena itu bungkusan tersebut sebaiknya disimpan dalam kotak karton, jauh dari sinar matahari. Ruang penyimpanan harus bersih, kering, sejuk dan bebas hama. Kelambu sebaiknya dipasang pada jendela untuk mencegah hama dan serangga memasuki ruangan. Makanan, deterjen, dan cat yang berbau tajam tidak boleh disimpan di ruangan yang sama.

Standar

| Persyaratan Pemerintah AS dan ASTA | |

|---|---|

| Kelembapan (%) | <9.0 |

| Kurkumin (%) | 5-6.6 |

| Minyak yang mudah menguap (%) | <3.5 |

| Benda asing (% berat) | 0,5 |

| Cetakan (% berat) | 3.0 |

Pemasok peralatan

Ini adalah daftar selektif pemasok peralatan dan tidak berarti dukungan dari Tindakan Praktis.

Situs web ini memuat daftar perusahaan di India yang memasok peralatan pengolahan makanan. http://www.niir.org/directory/tag/z,,1b_0_32/fruit+processing/index.html

Pengering

Mesin Acufil SF No. 120/2, Kantor Pos Kalapatty Coimbatore - 641 035 Tamil Nadu, India Telp: +91 422 2666108/2669909 Faks: +91 422 2666255 Email: acufilmachines@yahoo.co.in acufilmachines@hotmail.com

http: //www.indiamart.com/acufilmachines/# produk

Pekerjaan Teknik Bombay 1 Kawasan Industri Navyug 185 Jalan Tokersey Jivraj Seberang Swan Mill, Sewree (W) Mumbai 400015, India Telp: +91 22 24137094/24135959 Faks: +91 22 24135828 Email: bomeng@vsnl.com http://web. archive.org/web/20170716041112/http://www.bombayengg.com:80/contact.html

Jaringan Pekebun Energi (PEN) No 5, Power House 3rd Street NRT Nagar Theni 625531 Tamil Nadu, India Telp: +91 4546 255272 Faks: +91 4546 255271 Email: info@pen.net.in http://web.archive. org/web/20090525090452/http://pen.net.in:80/Contactus.asp

Premium Engineers Pvt Ltd Plot No 2009, Fase IV, GIDC Vatva, Ahmedabad 382445 India Telp: +91 79 25830836 Faks: +91 79 25830965

Peringkat dan Perusahaan A-p6/3, Kawasan Industri Wazirpur Delhi – 110 052, India Telp: +91 11 7456101/ 27456102 Faks: +91 11 7234126/7433905 Email: Rank@poboxes.com

Industrias Technologicas Dinamicas SA Av. Los Platinos 228 URB industrial Infantas Los Olivios Lima Peru Telp: +51 14 528 9731 Faks: +51 14 528 1579

Industri Ashoka Kirama Walgammulla Sri Lanka +94 71 764725

Insinyur Kundasala Jalan Digana Kundasala Kandy Sri Lanka Telp: +94 8 420482

Alvan Blanch Chelworth, Malmesbury Wiltshire SN16 9SG Inggris Telp: +44 1666 577333 Faks: +44 1666 577339 enquiries@alvanblanch.co.uk www.alvanblanch.co.uk

Mitchell Dryers Ltd Denton Holme, Carlisle Cumbria CA2 5DU Inggris Telp: +44 1228 534433 Faks: +44 1228 633555 webinfo@mitchell-dryers.co.uk http://mitchell-dryers.co.uk/

Mesin pengiris

Institut Pusat Teknik Pertanian Nabi Bagh Berasia Jalan Bhopal 462 038 Madhya Pradesh India Telp: +91 755 2737191 Faks: +91 755 2734016 direktur@ciae.res.in http://web.archive.org/web/20130421115516/http: //www.ciae.nic.in:80/

Eastend Engineering Company 173/1 Gopal Lal Thakur Road Calcutta 700 035 India Telp: +91 33 25536937 Faks: +91 33 23355667

Gardners Corporation 158 Golf Links New Delhi 110003 India Telp: +91 11 3344287/3363640 Faks: +91 11 3717179

Mesin pembersih/abrasif

Institut Pusat Teknik Pertanian India (lihat di atas)

Gardners Corporation India (lihat di atas)

Tas Pos Ekspor Rajan Universal no 250 162 Linghi Chetty Street Chennai 600 001 India Telp: +91 44 25341711/25340731/25340751 Faks: +91 44 25342323 rajeximp@vsnl.com http://web.archive.org/web/20111219111013/ http://www.rajeximp.com:80/rajeximp/contact.html

Narangs Corporation P-25 Connaught Place New Delhi 110 001 India Telp: +91 11 2336 3547 Faks: +91 11 2374 6705

DISEG Av Jorge Carlos Mariategui 1256 Villa Maria del Triunfo Lima Peru Telp: +51 14 283 1417

Servifabri JR Alberto Aberd No 400 Urb Miguel Grau (Ex Pinote) San Martin de Porres Lima Peru Telp/Faks: +51 14 481 1967

Servifabri SA Peru (lihat di atas)

Crypto Peerless Ltd Bordesley Green Road Birmingham B9 4UA Inggris

Mesin penggilingan dan penggiling

Institut Pusat Teknik Pertanian India (lihat di atas)

Gardners Corporation India (lihat di atas)

Premium Engineers PVT Ltd India (lihat di atas)

Rajan Universal Ekspor PVT Ltd India (lihat di atas)

Insinyur Kundasala Sri Lanka (lihat di atas)

Mesin pengemas dan pelabelan

Mesin Acufil India (Lihat di atas)

Gardners Corporation India (lihat di atas)

Mesin Pengemas Gurdeep Senyawa Harichand Mill LBS Marg, Vikhroli Mumbai 400 079 India Telp: +91 22 2578 3521/577 5846/579 Faks: +91 22 2577 2846

MMM Buxabhoy & Co 140 Sarang Street Lantai 1, Dekat Pasar Crawford Mumbai India Telp: +91 22 2344 2902 Faks: +91 22 2345 2532 Email: yusufs@vsnl.com; mmmb@vsnl.com; yusuf@mmmb.in

Narangs Corporation India (lihat di atas)

Orbit Equipments Pvt Ltd 175 - B, Plassy Lane Bowenpally Secunderabad - 500011,Andhra Pradesh India Telp: +91 40 32504222 Faks: +91 40 27742638 Situs web: http://orbitequipments.com/

Alvan Blanch Inggris (lihat di atas)

CS Bell Co 170 West Davis Street PO Box 291 Tiffin Ohio 44883 AS Telp: +1 419 448 0791 Faks: +1 419 448 1203

Unit Mesin Pharmaco No.4, S.No.25 A Opp Savali Dhaba, Nr.Indo-Max Nanded Phata, Off Sinhagad Rd. Pune – 411041 India Telp: +91 20 65706009 Faks: +91 20 24393377

Pangkat dan Perusahaan India (lihat di atas)

Banyong Engineering 94 Moo 4 Sukhaphibaon No 2 Rd Kawasan Industri Bangchan Bankapi Thailand Telp: +66 2 5179215-9

Pusat Pengembangan Teknologi dan Peralatan (LIDUTA) 360 Bis Ben Van Don St Distrik 4 Kota Ho Chi Minh Vietnam Telp: +84 8 940 0906 Faks: +84 8 940 0906

Universitas Sains dan Teknologi John Kojo Arthur Kumasi Ghana

Alvan Blanch Inggris (lihat di atas)

Peralatan Pengemulsi Industri KOS A18 Lantai Dua, Gedung 1, Shunlian Machinery Plaza, Kota ChenCun Foshan Cina Telp: +86 0757 29318541 Situs web: http://www.emulsifyingmixer.com

Kontak

Kontak berikut harus dapat memberikan informasi lebih lanjut:

Institut Penelitian Rempah India (IISR) Marikunnu PO, Kalikut Kerala India 673012 Telp: +91 495 2731346 +91 495 2730294 Email: parthasarathy@iisr.org; rdinesh@iisr.org Situs web: http://web.archive.org/web/20120426091327/http://www.iisr.org:80/package/index.php?spice=Turmeric&body=Overview

Institut Teknologi India (IIT) Bombay Powai Mumbai 400076 India Telp: +91 22 2572 2545 Faks: +91 22 2572 3480 Situs web: http://web.archive.org/web/20170425034047/http://www.ircc. iitb.ac.in/webnew/

Bacaan lebih lanjut

Ringkasan Teknis Tindakan Praktis – Ringkasan Teknis Tindakan Praktis Pengeringan – Ringkasan Teknis Tindakan Praktis Pengolahan Rempah – Pelabelan produk makanan FAO InPHO www.fao.org/inpho/content/compend/text/ch29/ch29_02.htm Indian Spices http://www. indianspices.com/html/spfarm_tum.htm

Tindakan Praktis Pusat Teknologi dan Pengembangan Schumacher Bourton-on-Dunsmore Rugby, Warwickshire, CV23 9QZ Inggris Telp: +44 (0)1926 634400 Faks: +44 (0)1926 634401 E-mail: inforserv@practicalaction.org. uk Situs web: http://www.practicalaction.org/ Dokumen ini dibuat oleh Dr. S. Azam Ali untuk Tindakan Praktis pada bulan Maret 2007. Dr. S. Azam-Ali adalah konsultan pengolahan makanan dan nutrisi dengan pengalaman lebih dari 15 tahun pengalaman bekerja dengan pengolah skala kecil di negara-negara berkembang.