Open source machine tools refer to a category of manufacturing equipment whose designs, specifications, and software are made freely accessible to the public under an open license.

Background[edit | edit source]

This Open Source Machine Tools (OSMT) collection serves as a comprehensive resource for listing and referencing existing open-source machine tools. These tools are physical artefacts designed and shared by the open-source community, aligning with the principles of open source hardware (OSH) and fostering innovation in the realm of manufacturing and engineering.

Through the means of collaboration and accessibility, these tools encourage open sharing of knowledge and foster community-driven innovation. Examples include 3D printers, CNC mills, laser cutters, pick and place machines. The range of machines continues for other areas like farming, robotics, metalwork, woodwork, scanning, forming, recycling and much more. This collection will focus on the overall machining in the context of FabLabs, Makerspaces and mobile applications.[1] It can be extended in the future.

Open source machine tools enable users, engineers and other peers to customize, modify, and contribute to the development of these tools, making advanced manufacturing technologies accessible to a diverse range of individuals, makers, and small businesses. The collaborative nature of open source communities ensures the possibility of continuous improvement, adaptability, and affordability, shaping the landscape of modern manufacturing.[2]

Benefits and Criteria[edit | edit source]

The collection highlights the benefits and criteria associated with open-source machine tools:

- Accessibility: Open-source machine tools make manufacturing capabilities accessible to a broader audience, empowering individuals and small businesses.

- Cost-Efficiency: Building or modifying machine tools based on open designs can be more cost-effective than purchasing proprietary equipment.

- Customization: Users can adapt and customize machine tools to suit their specific needs, fostering innovation.

- Collaboration: The open-source community provides valuable feedback and improvements, resulting in better designs.

- Education: OSH machine tools are excellent resources for educational purposes, teaching engineering and manufacturing skills.

All Open Source Machine Tools need to be openly licensed.

All Open Source Machine Tools need available (technical) documentation.

All Open Source Machine Tools should have at least prototype status.

Example Communities[edit | edit source]

This references exemplary projects and communities that adhere to open-source principles in the field of machine tools:

- OpenBuilds: Most diverse Open Source CNC Machine Community. Offers open source plans for building various CNC machines, including routers, laser cutters, and 3D printers. Learn More

- Open Source Ecology - GVCS: The Global Village Construction Set is an Open Source Hardware project that includes plans for a wide range of machine tools and agricultural equipment. Learn More

- Sienci Labs: Provides open source plans and allowing users to build a versatile CNC milling machine. Learn More

- Precious Plastic: Focuses on open-source machines for recycling plastic, playing a vital role in sustainable manufacturing. Learn More

- Inmachines: Provide Open Source Machines for Fab Labs, including CNC, 3D print, laser cutting and more (not all documentation yet available, see GitHub Repositories). Learn More

Disclaimers[edit | edit source]

Unclear or proprietary licensed content (e.g. NC licensed) will not be counted as OSMT but there is a separate "Open Source inspired" List to check for inspiration. USE WITH CAUTION!

Be aware that documentation may be incomplete in some cases. For a reference on good documentation practices, you can check DIN SPEC 3105. Users are advised to consult additional sources or community channels for supplementary information.

Some projects may exist in different development stages, ranging from prototypes to certified products. Users should consider these variations and additional qualifications when evaluating a project's suitability for their specific needs. Note: (re)production of projects via other community members is usually a good indicator for readiness.

A project's community activity, such as forums, discussions, and reproductions, can be indicative of solid community backing. However, users are advised to actively participate in community channels for assistance and verify the project's reliability.

Consider the target audience specified in the documentation, as projects may cater to amateurs/learners or professionals/engineers. Understanding the intended user base is crucial to avoiding false expectations and aligning the project with specific skill levels.

Please note that projects might have old versions or outdated releases. Users are encouraged to check for the latest stable releases and updates to ensure compatibility and access to new features. Good practice will have "commit often, release early" policies and active community management.

The term "N.A." may indicate information that is not readily available or not easy to find. Users are encouraged to seek additional information from relevant sources or community channels. Contributions welcome.

Types of Open Source Machine Tools[edit | edit source]

3D Printing[edit | edit source]

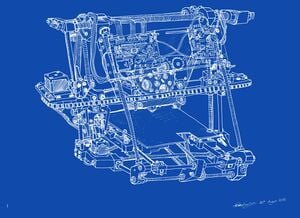

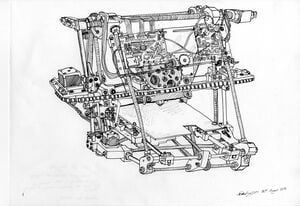

Open source 3D printers, exemplified by popular models such as the Prusa i3, are at the forefront of additive manufacturing. These machines employ the ingenious technique of layering materials, primarily thermoplastics, to bring three-dimensional objects to life.

Distinguished by their versatility, open source 3D printers offer various variations of additive manufacturing technologies, including Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS). This diverse range of printing methods caters to a multitude of applications, providing users with the flexibility to choose the most suitable technology for their specific needs.

In the realm of rapid prototyping, custom manufacturing, and even intricate medical modelling, open source 3D printers play a crucial role. Their accessibility, coupled with the historically collaborative nature of open-source, underscores their significance in community driving innovation and the world of three-dimensional digital fabrication.

The origins of Open Source Hardware (OSH) go back to the old first DIY RepRap designs. 3D Printers are therefore the historically speaking oldest OSMT and heavily inspired communities to find completely new approaches to development of technology. See The Cathedral and the Bazaar essay.

CNC Milling[edit | edit source]

Open source CNC mills, with the OpenBuilds WorkBee as a typical example, harness the power of Computer Numerical Control (CNC) to intricately cut, carve, and shape materials such as wood, metal, and plastics. The hallmark of these machines lies in their modular designs and diverse configurations, allowing them to cater to a wide spectrum of machining needs. Some special models are used as a router to mill PCB designs.

At their core, these CNC mills consist of key components like the spindle, axis system, and a control system equipped with open-source firmware like GRBL. The community-driven nature of their designs fosters a culture of customization and collaboration, empowering users to adapt the machines to their specific requirements. Some open source inspired machines are listed separately to show the variety of models especially in the MPCNC (mostly printed) context with their very active community and easy to reverse engineer as OSMT.

CNC mills find application across various industries, including woodworking, metalworking, PCB milling, and the fabrication of custom parts. The versatility and precision offered by open source CNC mills underscore their significance in democratizing advanced machining technologies and making them accessible to a broad range of users.

Laser Cutting[edit | edit source]

Laser cutters, represented by models like the Universal Laser Systems VLS6.60 and the Glowforge Pro, harness the power of focused laser beams to achieve precise cutting and engraving across a diverse array of materials. These innovative machines offer a dynamic range of cutting capabilities, thanks to the utilization of CO2, fiber, and diode lasers. (Which also represents most of the power differences.)

At the heart of these laser cutters are key components, including the laser source, optics system, motion control system, and a control interface driven by sophisticated software like LightBurn (free, not open source) or UGS (open source). This combination of hardware and software ensures not only precision in cutting but also seamless integration with user-friendly interfaces for efficient operation.

Whether in architectural models, custom signage, medical device fabrication, or personalized products, also in FabLabs laser cutters have become indispensable tools. Currently there are still not many open-source projects to reference.

Pick & Place[edit | edit source]

Open source Pick and Place machines, exemplified by small-scale solutions like LumenPnP, support the precision assembly of electronic components onto Printed Circuit Boards (PCBs). These machines leverage features such as vision systems, specialized placement heads, and efficient feeder systems to ensure accuracy throughout the assembly process. By automating the repetitive task of component placement, these open-source machines contribute to enhanced efficiency, reduced production time, and the democratization of electronics manufacturing. Small-Scale machines of this kind are also suited to be applied in mobile use-cases or home manufacturing automation or pre-production assembly.

Other machine types and the scope[edit | edit source]

Empowering Communities with Open Source Machine Tools

In the context of small-scale applications, mobile makerspaces, and FabLabs in crisis regions, post-conflict, and community-building contexts, open-source machine tools emerge as transformative agents. Robotics, fueled by open-source principles, offers a nimble and accessible automation solution for tasks ranging from healthcare in crises to community-driven initiatives.

Welding tools become vital in construction projects, empowering local communities to rebuild and revive post-conflict areas. Waterjet Cutting, with its precision and versatility, becomes a cornerstone for small-scale manufacturers, allowing them to create intricate designs even in resource-limited settings.

Injection Molding, within an open-source framework, empowers local entrepreneurs to produce essential plastic products tailored to community needs. Electric Discharge Machines (EDM), Punch Pressing, and Shearing/Bending machines, when open-source, enable small-scale fabrication initiatives, contributing to economic revitalization.

Lathing, driven by open-source innovations, facilitates local production of components, enhancing the self-sufficiency of communities. Scanning tools, with open-source adaptability, become essential in documenting cultural artifacts and fostering community-based preservation efforts.

In the realm of farming, open-source tools optimize small-scale agriculture (such as FarmBot), promoting sustainable, educational practices and bolstering food security. The focus on open source in these contexts promotes accessibility, adaptability, and collaboration, making machine tools catalysts for empowerment and resilience within crisis regions and community-building initiatives.

These are just a few more of the variety of types of machine tools to be found in the communities.

The collaborative nature of open-source development fosters a culture of shared innovation, enabling diverse communities to adapt existing machine tools or create new ones that suit their specific needs. This decentralized approach to technological advancement empowers local makers and communities to address challenges unique to their regions.

In crisis regions, the availability of open-source machine tools can facilitate rapid response efforts, enabling the production of essential components, medical devices, or even rebuilding infrastructure. For community-building initiatives, it opens doors to sustainable economic development, fostering self-sufficiency through localized manufacturing.

Moreover, the online accessibility of open-source machine designs acts as a catalyst for skill development and knowledge sharing. Makers, innovators, and enthusiasts globally can learn, iterate, and contribute to the evolution of machine tools. This collective effort not only propels technological advancements but also nurtures a sense of global solidarity.

In essence, the ongoing expansion of open-source machines and hardware availability online signifies more than just technological progress; it symbolizes a shift toward inclusivity, empowerment, and the creation of a collaborative ecosystem where the potential for positive change knows no boundaries.

A growing ecosystem of Open Source Machine Tools will be listed below. Feel free to contribute.

Collection Overview[edit | edit source]

| Project Name | Machine Type | Characteristics | Development Entity | Website | License | Source | Docs | Community Channel | Notes |

|---|---|---|---|---|---|---|---|---|---|

| RepRap Mendel | 3D Printer | FDM | RepRap | reprap.org | GPL 2.0 | RepRap Wiki | User Guide | Community Forum | The historical root and ancestor of all modern desktop 3d-printers as open-source and self-replicating machines, by Adrian Bowyer ... this is where it all began. |

| Voron 2.4 | 3D Printer | FDM | Voron | vorondesign.com | GPL 3.0 | GitHub | Documentation | Community Forum | Advanced, very fast printing |

| Lulzbot TAZ Workhorse | 3D Printer | FDM | Lulzbot | lulzbot.com | GPL 3.0 | Community Forum | beginner machine | ||

| Positron V.3 | 3D Printer | FDM | Positron3D | positron3d.com | CC-BY-SA 4.0 | GitHub | Wiki | Discord Channel | 180x185x180mm, Advanced, prints upside down, foldable, portable |

| Prusa i3 MK3S | 3D Printer | FDM, MultiMaterial | Prusa | prusa3d.com | GPL 2.0 | GitHub | Documentation | Community Forum | Upgrade Options for Multimaterial, beginner friendly, one of the most popular printer adaptations of the RepRap Mendel History line, very good assembly documentaion |

| Elegoo Mars3 4K | 3D Printer | SLA | Elegoo | elegoo.com | GPL 3.0 | GitHub | Documentation | n.a. | 143x89x175mm, 4K, OSHWA Certified UID CN000010, entry-level |

| Maslow4 | CNC Mill | Tensegrity CNC-Mill, "StringHanger" | MaslowCNC | Maslow4 (Open Source CNC router) | CC-BY-SA 4.0 | GitHub | GitHub | Kickstarter | 8'x4' Large Format, Spindle hangs on Strings |

| PrintNC | CNC Mill | Gantry | ThreeDesign | Product Page | CC-BY 4.0 | GitHub | Wiki | Discord | 1200x900, but variable sizes are possible due to a material-calculator, steel frame, high performance, contains 3D-printed parts, well documented but Source files in parts missing. STL print files available |

| OLSK Small CNC V.2 | CNC Mill | Gantry | Inmachines | inmachines.net | CERN OHL W 2.0 | GitHub | Workbook | FabCity Hamburg | 400x500x140, additional toolchanger and coolant system |

| OLSK Large CNC V1 | CNC Mill | Gantry | Inmachines | inmachines.net | CERN OHL W 2.0 | GitHub | Workbook | FabCity Hamburg | 2500x1250x300mm, retractable and adjustable wheels |

| OpenBuilds OX | CNC Mill | Gantry | Open Builds | openbuilds.com | CC-BY-SA 4.0 | OpenBuilds | OpenBuilds | Forum | 310x480,file format Sketchup, many build-instructions on youtube-channel |

| CubeFactory 2 | 3D Printer | portable | Bernd Muschard, Jeremy Bonvoisin | cubefactory.org | CC-BY-SA 4.0 | GitHub | GitHub | n.a. | 801x399x522mm, integrated shredder and recycler, photovoltaic panels and batteries for energy supply, 8 hours of autonomous printing without powersupply, example with Prusa i3 Model integrated |

| Resilient 3-D Printer for Humanitarian Crisis Response | 3D Printer | portable | Benjamin L. Savonen, Tobias J. Mahan, Maxwell W. Curtis, Jared W. Schreier, John K. Gershenson and Joshua M. Pearce | Development of a Resilient 3-D Printer for Humanitarian Crisis Response | CERN-OHL-S 2.0, GPL 3.0 | Source | Appropedia | n.a. | Software GPLv3 and Hardware CERN OHL or GPLv3 unclear.

200x200x200mm (est.), power supply can accept either 110 or 220 volts |

| Makers Mill | CNC Mill | Bed-Mover | Open Source Ecology Germany | Wiki Page | CC-BY-SA 4.0 | GitHub | Wiki Page | OSE Germany Community | 320x160x40mm, 500W Spindle, GRBL, based on the UPKlib (Universal Prototyping Kit 3D Library, UniProKit), OSHW-approved compliance with DIN Spec 3105 |

| D3D CNC Circuit Mill | CNC Mill | Belt-Driven, PCB milling | Open Source Ecology US | Wiki Page | CC-BY-SA 4.0, GPL 3.0 | Source | Wiki Page | License notes a bit unclear, but open source compatible. 140x200, based on the Open Source Ecology D3D design system. | |

| OpenBuilds Sphinx 1050 | CNC Mill | Gantry | OpenBuilds | openbuilds.com | CC-BY 4.0 | Source | Documentation | Forum | 834x325x85, file format Sketchup, manyx build-instructions on youtube-channel |

| LongMill MK2 | CNC Router | Gantry | Sienci Labs | sienci.com | CC-BY-SA 4.0, GPL 3.0 | Source | Documentation | Forum | 820x872x114mm, Community Project, Software GPLv3 |

| Buildlog.Net 2.x Laser | Laser Cutter | CO2 | Barton Dring | buildlog.net | CC-BY-SA 3.0 | Source | buildlog.net | Forum | 304x508, 40W CO2 |

| LaserSaur | Laser Cutter | CO2 | NortD Labs | lasersaur.com | CC-BY-SA 4.0, GPL 3.0 | GitHub | GitHub Wiki | Google Group | 1220x610mm, 120W CO2 |

| Laser4DIY | Laser Cutter | Copper Ablating | FabLab Munich | fablab-muenchen.de | CERN-OHL-P 2.0 | GitHub | Wiki | Channels | 165x165, special laser for pcb fabrication |

| OLSK Small Laser | Laser Cutter | CO2 | Inmachines | inmachines.net | CERN-OHL-W 2.0 | GitHub | Workbook | FabCity Hamburg | 600x400mm, 40W CO2 |

| OLSK Large Laser | Laser Cutter | CO2 | Inmachines | inmachines.net | CERN-OHL-W 2.0 | GitHub | Workbook | FabCity Hamburg | 1000x700, 75W CO2 |

| OpenBuilds Acro 1010 | Laser Cutter | Diode | OpenBuilds | openbuilds.com | CC-BY 4.0 | Source | openbuilds.com | Forum | 800x800, many different sizes up to 1300x1300 customizable, sketchup files, many instructions on youtube-channel |

| OpenBuilds TableTop 50W | Laser Cutter | CO2 | Pedro Fernandez | openbuilds.com | CC-BY 4.0 | openbuilds.com | openbuilds.com | Forum | 300x600, stable case, Ruida-controller, many instructions on youtube-channel, some source files missing |

| LumenPnP | Pick and Place | Benchtop, Dual nozzles | Opulo | opulo.io | GPL 3.0 | GitHub | GitHub Wiki | Discord | Maximum PCB Size 225x400mm, OSHWA UID US002570 |

| OpenPnP-OpenBuilds | Pick and Place | Benchtop | OpenBuilds | CC-BY-SA 4.0 | GitHub | GitHub Wiki | Google Group | OpenPnP compatible SMT pick and place machine based on OpenBuilds linear motion components. A bit outdated | |

| OpenBuilds Acro CoolPnP | Pick and Place | Benchtop | Greg Wroblewski | openbuilds.com | Apache License 2.0 | GitHub | openbuilds.com | Forum | working prototype |

| PixiePlacer | Pick and Place | Benchtop | PixiePlacer | GitHub | CC0-1.0 | GitHub | GitHub | n.a. | MGN12-Rails |

| FarmBot CNC | Robot | Gantry | CNC Farming Bot | farm.bot | AGPL 3.0 | farm.bot | farm.bot | Forum | Open-source CNC farming equipment for precision planting, watering, and weeding. Software has MIT and Apache Licenses to be found on GitHub |

Open Source inspired Machine Tools[edit | edit source]

These additional machines cover various domains such as 3D printing, CNC routing, laser cutting, production equipment, and plastic recycling, showcasing the diversity of open-source inspired projects available. However, the source and licensing information, while available for some, might not always be explicitly provided for every project. The listed projects are notable for their community-driven development, open design approach, and popularity in fostering innovation and accessibility for makers.

| Project Name | Machine Type | Characteristics | Development Entity | Website | License | Source | Docs | Community Channel | Notes |

|---|---|---|---|---|---|---|---|---|---|

| Ultimaker S7 | 3D Printer | FDM | Ultimaker | ultimaker.com | non-commercial | n.a. | n.a. | Community | Software Open Source (GPL 2.0) and NC licensed Hardware. In general not very clear licensing. Intermediate application. |

| Big Pellet 3D Printer | 3D Printer | FDM | Tolocar | Big Pellet 3D Printer (Tolocar) | unclear | n.a. | n.a. | n.a. | in development |

| IndyMill | CNC Mill | Belt-Driven | Indystry Nikodem Bartnik | indystry.cc | unclear | GitHub | GitHub | n.a. | 520x400x115mm, Small Spindle (Dremel Derivat), contains 3d-printed parts, unclear license, source available. Youtube videos. |

| DeineFraesmaschine | CNC Mill | Gantry | Christoph Loibl | deinefraesmaschine.de | unclear | Documentation | Documentation | n.a. | 350x380x160mm, water-cooled spindle, nice housing, high quality construction, well documented, mach3 software, industrial lookandfeel |

| VolksFraese VF1 | CNC Mill | Belt-Driven | UnclePhil | unclephil.de | non-commercial | Documentation | Documentation | 1000x500x150, low cost, contains 3d-printed parts, nice control-board, well documented, non-open-source | |

| MPCNC - mostly printed CNC | CNC Mill | Belt-Driven | V1 Engineering | V1 Engineering | non-commercial | Source | Documentation | Forum | Variable size, up to 1220x1220, low cost, consists mostly of 3d-printed parts and some other parts like tubes, that are available on any hadrware-store. No reselling of parts or distributing in general. Some community agreements seem to work though collaboration is legally tricky via CC-BY-NC-SA License. |

| Smoothieboard/OpenPnP | Pick and Place | Dual Head | John Deglavina | hackaday.io | unclear | OpenPnP-OpenBuilds | hackaday.io | Smoothieboard Control, working prototype, build on the OpenPnP-OpenBuilds model, unclear License but probably Apache-v2 like the origin. |

Future Development Scenarios[edit | edit source]

Some of the "Open Source inspired Machine Tools" may turn fully open source and add collaborative value to the community. There are yet a lot of innovations build upon the existing models derived from the early machine models in both directions open source/source available to proprietary and vice versa. So here are a few proprietary technology mentions that shift the trend towards mobile applications and modular scalable designs to get inspiration from.

- 3D Printers (proprietary): Creality K1 or fast newcomers like Bambulab X1-carbon and P1S are popular models in the market with very unique characteristics. Snapmaker 2.0 Models can even switch into milling or laser mode and have a tool-changer modularity included.

- CNC Mills (proprietary): Some CNC-Mills which are also quite popular in the FabLab-Community are Stepcraft, X-Carve, Shapeoko.

- Laser Cutter (proprietary): Diode-Laser have meanwhile achieved an impressive and powerful peformance, with wattages from 20W up to 80W or even more, which makes them well suited for laser-cutting tasks. Popular are the xTool S1, the Creality Falcon2, the SF-A9 and CO2-Lasers like the chinese K40.

Follow-up Research & Scope[edit | edit source]

Other exemplary OSMT areas to watch out for and not part of the initial scope of this article:

- Robotics

- Welding

- Plasma Cutting

- Waterjet Cutting

- Injection Molding

- EDM

- Punch Pressing

- Shearing/Bending

- Lathing

- Scanning

- Farming

- Textile

- Automotive

- Energy Systems

- Healthcare

- Chemical Processing

- Recycling/Waste Management

The overall research and classification of machine readiness, community activity and metadata can emerge from this collection and might imply scientific research and analysis. It might imply new standards and database tools for evaluation.

Additionally the following subjects could be connected articles to extend the Collaborative Use-Case within the future research and inspiration.

- Open Source Energy Systems to power OSMT

- Open Source Health Tools to support mobile medical labs

- Open Source Science Tools to connect OSMT with sepecific science tools (like microscopes etc)

- Open Source Household Tools to bridge the maker tools and industries towards a repair and end-user friendly set of tools (like a mixer, washing-machine etc.)

- etc.

On the listing of existing open source hardware the is a current collection and discussion ongoing via GOSH Forum. Also interesting tools e.g. the "Library of Open Source Hardware" LOSH-Reporter using the LOSH-Krawler to gather data in RDF format [1].

Software for Open Source Machine Tools[edit | edit source]

The scope of open-source software in the field of manufacturing and machine tools is vast and transformative. Open source software plays a crucial role in enhancing accessibility, customization, and collaboration within the manufacturing ecosystem.

Engineering software is often still proprietary, in order to assure as much open and accessible experience as possible here are some Software solutions to consider. For further details and extended collection visit the Software Tool Database of the Open Toolchain Foundation.[3]

- Control Systems and Firmware:

- Open-source control systems and firmware, such as GRBL for CNC machines like mills or LaserGRBL for Lasers, as well as some processor-platform-specific derivates like GRBL_ESP32 (now renamed to FluidNC), which ads WiFi-control to the system. For 3D-printers Marlin or Klipper provide a flexible and customizable foundation. Users can modify code to adapt machines for specific tasks or integrate additional features.

- Design and CAD Software:

- Open-source Computer-Aided Design (CAD) software, like FreeCAD or LibreCAD, allows users to create, modify, and visualize 3D models. For the development of electric circuit schematics and pcb-layout KICad is the first choice. This promotes interoperability and flexibility in designing components for manufacturing.

- CAM (Computer-Aided Manufacturing) Software:

- CAM software, such as FreeCAD Path Workbench or LinuxCNC, converts CAD designs into toolpaths for CNC machines. A special kind of CAM is needed to prepare the extrusion-path for 3D-printers, because the software not only has to compute the movements on different layers, but also controls the molten plastics output on the extruder. This can be achived with a "slicer"-software, like PrusaSlicer and BambuStudio, which are both derivates of their ancestor Slic3r, or Cura.

- Machine Control Interfaces:

- Open-source interfaces, like Universal Gcode Sender (UGS) or bCNC, enable users to control CNC machines and 3D printers.

- Simulation and Visualization Tools:

- IoT and Automation:

- Open-source frameworks, such as Node-RED or OpenPLC, empower users to implement IoT (Internet of Things) and automation solutions in manufacturing. This can include sensor integration, data acquisition, and control systems automation. Also applications as Arduino is providing are used in many small and medium application

- Community Collaboration Platforms:

How to contribute[edit | edit source]

In the growing field of Open Source Machine Tools many new projects will emerge in the coming years, consider contributing to this collection.

1. New Entries: If you come across open-source machine tool projects with open-source licenses not included in this collection, please include them.

2. Provide Updates: If you have updates or additional information about any of the listed projects, share them to ensure accuracy.

3. Collaborate: If you're a part of an open-source machine tool project with an open-source license, collaborate to improve the listing and share insights.

4. Spread the Word: Promote the Open Source Machine Tools collection within relevant communities to help others discover and benefit from these projects.

The Project Collection embodies the spirit of open design, collaboration, and innovation in the realm of machine tools with open-source licenses. By contributing and participating, you contribute to the democratization of manufacturing capabilities and the growth of the Open Source Hardware community.

References[edit | edit source]