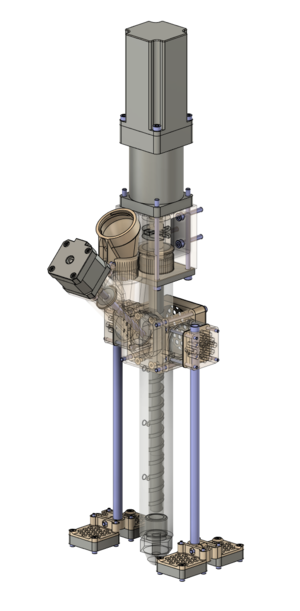

This project aims to create a working prototype of a small universal pellet extruder that works in horizontal and vertical orientation. You can 3D print in a vertical position. Extrude filaments or inject plastic into a mold in a horizontal position.

Extruder[edit | edit source]

The principle of operation is simple. The electric motor rotates the gearbox, which reduces the speed but increases the torque of the main screw. A thermoplastic pellet is poured into the feeder and transported to the main compression screw. The granule melts from the pressure and temperature and exits through the nozzle in an elastic state.

An extruder can work as a stand-alone machine or be part of another machine such as a 3D printer.

Open source[edit | edit source]

The latest version of files for the assembly of the extruder V0.1 alpha version[edit | edit source]

Keep in mind that development and testing are still ongoing, this is an alpha prototype and the configuration may change in the near future.

We plan to increase the power of the main engine and replace the feeder engine. Instead of stepper nema 17, we will install a DC motor with a gearbox. We also plan to improve the efficiency of the cooling system.

Bill of Materials[edit | edit source]

| Type | Item | Qyt. | URL (Aliexpress) | Price (€) | Notes |

|---|---|---|---|---|---|

| Extruder KIT | Extruder KIT 16 mm screw, barrel, nozzle 3 pc. band heaters | 1 | Link | €245,00 | 57 Size Flange, 2.5mm Nozzle, 3x pc. band heaters |

| Bearing | Single row angular contact ball bearing | 2 | Link | €18,00 | Better buy 3 or 4 |

| Coupling | Oldham shaft coupling 14x14 mm with 5 mm key | 1 | Link | €29,00 | Text to seller that you need key 5 mm |

| Gearbox | Gearbox 16:1 Nema 23 | 1 | Link | €40,00 | Ratio 16:1 |

| Motor | Nema 23, 102 mm, 3 N.m, 5A with driver | 1 | Link | €45,00 | |

| Motor | Nema 17, 48 mm | 1 | Link | €15,00 | |

| Coupling | D20L25 3D Printer Part Lead Screw Coupler 5x6 mm | 1 | Link | €2,00 | Better buy more couplings with different inner diametrs (5x8, 5x10, 6x6, 6x8) |

| Heat Sink | Heat Sink for 40mm fan | 2 | Link | €13,40 | |

| Cooling Fan | Cooling Fan 4020 24V | 4 | Link | €11,60 | 24V |

| Cooling Fan | Cooling Fan 4010 24V | 4 | Link | €10,70 | 24V |

| Power Supply | Power Supply 24V 15A | 1 | Link | €24,00 | 24V |

| Motor controller | Stepper Motor Controller | 2 | Link | €9,00 | |

| Fastners | M5x100mm 12.9 class steel | 4 | Link | €17,00 | |

| Fastners | M5x30mm 12.9 class steel | 4 | Link | €7,00 | |

| Fastners | M4x70mm stainless steel | 4 | Link | €11,00 | |

| Fastners | M4x40mm | 8 | Buy local | ||

| Fastners | M4x25mm | 2 | Buy local | ||

| Fastners | M3x15 | 8 | Buy local | ||

| Fastners | M3x25 | 8 | Buy local | ||

| Tube | Aluminium tube D10 mm length 245 mm | 2 | Buy local | ||

| Drill | Drill 6 mm | 1 | Buy local | ||

| Temperature sensor | Temperature Sensor PT100 1m | 3 | Link | €17,00 | PT100 |

| Temperature controller KIT | Temperature controller REX-C100 + 40DA SSR Relay + heat sink | 3 | Link | €33,00 | |

| Button | Emergency stop push button 1NC 220V | 1 | Link | €1,00 | Buy local |

| Button | Start green button 1NO 220V | 1 | Link | €2,00 | XB2-BA31 GREEN Buy local |

| Button | Stop red push button 1NC 220V | 1 | Link | €2,00 | XB2-BA42 RED Buy local |

| Contactor | AC Three-pole contactor 220V 6A+ | 1 | Link | €19,00 | 220V Buy local |

| Socket plug | Socket plug 16A+ | 1 | Buy local | ||

| Wire | Silicone 18 AVG 10+ meters | 10 | Link | €6,00 | Buy local |

| Wire | 20-22 AWG 10+ meters | 10 | Link | €3,00 | Buy local |

| Wire connector | Bridge type zero line bar 4p | 2 | Link | €3,00 | Buy local |

| Wire connector | Bridge type zero line bar 8p | 2 | Link | €4,00 | Buy local |

| Wire connector | Dual row terminal block 6P | 1 | Link | €1,00 | Buy local |

| Wire connector | Quick Connector Spring Wire | 20 | Link | €2,00 | Buy local |

| €591,30 | |||||

Tests[edit | edit source]

Last[edit | edit source]

For tests we use CNC milling machine to move the extruder in space. At this stage of development, the extruder is mounted on existing frames of CNC routers.

The extruder parameters are changed manually. The temperature is regulated on the termocontrollers depending on the type of plastic we use and the speed as well. We set the main motor speed on the driver.

We generated the gcode in Rhino Grasshopper and edited it manually so that the NC Studio control program correctly executes the commands.

The vases are printed from bHIPS granules.We are currently testing different plastic options and will later make a table of temperature and speed parameters.

As a build plate, we used scratched MDF and then scotch tape pasted on a mirror. We also used crushed PS, but the particle size was too large and the feeder was clogged.

We wiil make more tests and share results. Stay tuned!

First[edit | edit source]

-

Electronics testing

-

Installation of the extruder on the CNC milling machine

-

Extruder testing

-

Spiral test gcode

-

Testing thermoplastics and print settings

-

The best print test samples

First steps[edit | edit source]

-

Extruder assembly scheme

-

Extruder main parts

-

Assembled extruder

-

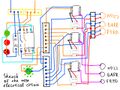

Sketch of the test electrical circuit

-

Test assembly of electricity

Contacts[edit | edit source]

If you have questions about the extruder, please e-mail me at bohdanskoblia@gmail.com or dm on instagram @bohdan