This article focuses on a sustainable way of fish farming called "Integrated multi-trophic aquaculture"W. Integrated multi-trophic aquaculture makes use of a integrated recyling system (often using tanks rather than using cages at sea). The normal method of using cages at sea is called "offshore fish farming". Another (equally inefficient method) is called a "flow-trough" system.

Overview[edit | edit source]

The advantages of a regular integrated recycling systems are:

- reduction of waste flows and energy consumption to a minimum

- the water polluted by excrement secreted by the fish is filtered and/or waste substances are converted by means of dentrification processes, allowing the water to meet the appropriate level of water quality for the fish. Ammonia and nitrate problematic is solved

- due to the nature of the system (closed system), there is no water pollution at all, and the fish are also unable to infect wild fish with sea lice. No antibiotics are spread in the wild, otherwise creating resistant diseases

"Sustainable" and "unsustainable" integrated recycling systems[edit | edit source]

Now an explaination on what we mean by "sustainable" integrated recycling systems. Normally, an integrated recycling system consists of the combining of algae or seaweed with mussels or fish. Both organisms are commercial organisms. Although this is indeed already an improvement over offshore and flow-trough systems (since the feces of the fish is absorbed to a degree by the seaweed or algae), there is still a lot of room for improvement.

This improvement includes the use of worms (earthworms or sandworms, depending on salinity level of the water). By using worms, non-commercial (faster growing, more efficient) algae can be used. Normally the algae is chosen for a specific function in mind.(ie for making biofuels, components for skin care products,...) Seaweed is sometimes also chosen, which is even less efficient. By just choosing the most efficient algae depending on the ambient climate (salinity level, temperature, nutrients in the water), and by using these algae to feed worms, the system speeds up, and an extra "buffer" is made (polluted water needs to be refreshed quite frequently, even before all nutrients have been absorbed by the plants).

The reason why seaweed is even less efficient is due to its nature. Seaweed requires a firm attachment point (in practice lines are used attached to buoys). Algae can just grow in the water, without an attachment point. The salinity level is also different (seaweed= 3-30 g NaCl/l, algae= 20-30g NaCl/l)

Finally, another issue are the fish densities in the tanks for phase 4: generally, a fish density of 20 to 25 kg per cubic metre needs to be uphold. Fish farmers today sometimes uphold a fish density of 30 to 50 kg per cubic metre. This decreases the texture of the fish, and also makes the fish susceptible to disease.

Lifecycle of fish[edit | edit source]

Before being able to design a integrated recycling system, we need to accustom ourselves with the lifecycle of the fish in question. We btw also immediatelly take into account the living requirements of the algae,... As an example, we show the lifecycle of salmon, which is a fish that spawns in fresh water (rivers) and once matured, heads out to salt water (sea), the latter is called the "smolting" phase.

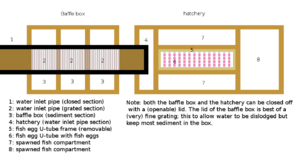

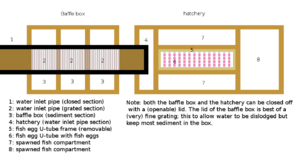

Salmon breeding starts with selecting and collecting broodstock: healthy and sexually mature male and female salmon. After fertilisation the eggs are placed on hatchery trays (trays with a height of 20 cm). One tray can contain 28,000 eggs. Several trays can be placed on top of each other. Incubation takes place and the so-called "eyed eggs" are transferred to hatcheries, where they grow into fry with a weight of 0.2 grams. In their natural environment eggs incubate at the end of the winter season or in the beginning of spring. The hatcheries, in which the salmon eggs incubate, are small tanks filled with fresh, oxygen rich water. The eggs are kept in semi-dark tanks with a water temperature of 4 to 8 oC. In order to fasten the incubation process, the temperature may be increased up to 10 oC. The hatchery water should be filtered continuously in order to prevent pollution and to avoid damage to the eggs.

In phase 0 the trays can easily be installed on top of each other and do not demand much room. One tray can contain up to 28,000 eggs. During phase 1, when eggs hatch and grow into fry, small hatcheries can be used. The Alevin and fry mainly exhaust their yolk sac and hide in the spawning area. A small fresh water tank is needed. It is essential that hatching takes place in dark conditions with a water temperature of 6 to 10 oC at most. Until the smolting phase the oxygen saturation level should amount to 70%. The oxygen level in wastewater should not be less than 6 mg per litre wastewater.[1]

As soon as the eggs incubate, the Alevins (baby salmon) are exposed to semi-darkness. Alevins grow into fry and consecutively into parr. Alevins and fry exhaust their yolk sac. As soon as fry reach a body weight of 0.2 grams, they are removed to a larger fresh water tank, where they remain until they grow into parr and reach a weight of 5 grams. Parr are fed with carefully selected and protein rich feed and grow into smolt. Continuous monitoring of the temperature (4 to 8 oC), the purity and the oxygen level of the water is of crucial importance in this breeding stage. Parr are mainly farmed in circular breeding tanks that may vary in size. The water is permanently circulated. Norwegian and Scottish breeding tanks have an average diameter of 3 to 4 metres and a depth of 1 metre. When salmon reaches a length of 12.5 cm and a weight of 80 grams, the smolting phase starts and salmon is transported to salt water cages. These cages are usually located in coastal waters or on the open sea close by off shore locations, which are becoming more and more popular. To stimulate the growing process, a special diet is administered to smolt salmon. The saltwater cages are usually square. They measure 30 by 30 metres and have a depth of 20 metres. A maximum density of 25 kilograms per cubic metre should be maintained, which corresponds with 5 adult salmon per cubic metre.

Salt concentrations of water[edit | edit source]

| Water salinity based on dissolved salts in parts per thousand (‰) | |||

|---|---|---|---|

| Fresh water | Brackish water | Saline water | Brine |

| < 0.5 | 0.5 – 30 | 30 – 50 | > 50 |

Design of the different tanks of the integrated recycling system[edit | edit source]

Tank requirements for salmon farming[edit | edit source]

| Phase | Salmon weight | Breeding tank | Conditions |

|---|---|---|---|

| Phase 0, eggs | Trays with 28,000 eggs each | Darkness, 6 to 10 °C, 70% oxygen saturation | |

| Phase 1, from Alevin to fry | Up to 0,2 grams | Fresh water tanks, 2 metres diameter | Semidarkness, 6 to 10 °C, 70% oxygen saturation |

| Phase 2, from fry to parr | Up to 5 grams | Semidarkness, 6 to 10 °C, 70% oxygen satruration | Darkness, 6 to 10 °C, 70% oxygen saturation |

| Phase 3, from parr to smolt | Up to 80 grams | Fresh water tanks, 4 metres diameter, depth 1 metre | 6 to 18 °C, 70% oxygen saturation |

| Phase 4, from smolt to adult salmon | Up to 5 kilograms | Seawater tanks of 10,000 m³ | Max. density: 20 kg salmon per m³, 6 to 18 °C, 60% oxygen saturation |

Integrated recycling system are made by companies such as Hesy,...

References[edit | edit source]

- http://web.archive.org/web/20120407123924/http://www.fryslan.nl/download.asp?objectID=32054&link=%5B002%5DEindrapportage+met+bijlage+20100422.pdf

- De kweek van zagers op landbouwbedrijven in Zeeland

- http://en.wikipedia.org/wiki/Fish_farming

- http://en.wikipedia.org/wiki/Aquatic_plant

- http://en.wikipedia.org/wiki/Alitta_virens