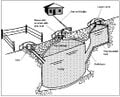

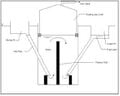

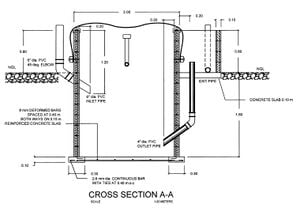

The design of most biogas systems can be traced to either the China Fixed Dome (CFD) with more than 6 million systems in-use (Fig. 1), or the India Floating Cover (IFC) with more than 2.9 million systems in-use (Fig. 2). The Philippine BioDigester Home Biogas System (HBS) is a product of both designs[1] (Fig. 3).

Its main advantages are that it is easier to build, less expensive and simpler to operate and maintain (clean & repair). It can be built as a Do-It-Yourself (DIY) project where expert masonry skills are not required and can be made using common and inexpensive materials available anywhere.

From pig manure, where 1-2 pigs excrete 1L (L=liter), biogas can be produced at the following rate:

- 20L/day = 250 Pesos[2] of biogas per month

- 40L/day = 500 Pesos[2] of biogas per month

- 60L/day = 750 Pesos[2] of biogas per month

The plan described in this project is for an 8 cubic meter digester (Fig. 3). It can produce up to 1,000 Pesos[2] of biogas per month from 80L/day of pig manure.

-

Figure 1: CFD (6+ million in use)

-

Figure 2: IFC (2.9+ million in use)

-

Figure 3: The Philippine BioDigester Home Biogas System (HBS)

Other advantages[edit | edit source]

- Does not need a concrete dome that is difficult to build, expensive and prone to leaks.

- Does not need a floating (metal) cover that corrodes, is expensive and difficult to operate.

- Does not need a stirring system that corrodes, is laborious and prone to leakage.

- The HBS has a simple sediment removal process that is easy and convenient to operate.

- The HBS can be located closer to the kitchen or place where the gas will be used to minimize piping problems like clogging and leaks.

Start-up instructions[edit | edit source]

- Inoculant preparation: three weeks before construction, place 100L of manure in a 200L drum and mix thoroughly with 50L to 100L of water. Preparing more is better if possible.

- Upon completion of HBS (all surfaces are fully dried), pour all the innoculant prepared into the HBS.

- Keep adding manure (thoroughly dissolved in water with 1:1 ratio) into the HBS until the outlet compartment is half full.

- With biogas outlet valve closed, after a few days, the HBS cover must begin to bulge (indicating it is filling up with gas.

- Try lighting or burning the gas produced. It should not ignite during the first few days or weeks as the gas produced is CO2 and not biogas. CO2 will actually extinguish flames or fire.

- Keep adding manure daily as needed. Feeding may be skipped occasionally, with no adverse effect.

Construction instructions[edit | edit source]

- Select a location for the HBS close to where the gas will be used. (We recommend collecting manure and bringing it to the HBS for feeding.)

- Choose a location away from trees whose roots can break the digester walls. (Min area: 2.5 mtr x 3.0 mtr)

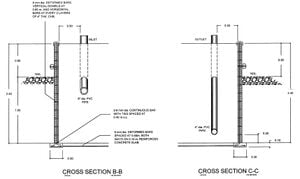

- Dig the ground 2.5m x 2.5m wide and 2.0m deep.

- Build the footings and reinforced concrete slab.

- Build the reinforced CHB walls. Upon reaching ground level, layout CHB walls for outlet compartment so that CHB and rebar interlocks are maintained. (Do not install all CHB for outlet compartment. See instructions below regarding cover installation.)

- The HBS has a below ground section of about 1.6 mtr and an above-ground section of 1.0 mtr. (This UNIQUE feature expedites sediment removal as described later in operation & maintenance.)

- After the CHB walls have dried, install the inlet, outlet and other pipes. Pipe locations may be changed to same or adjacent sides if preferred or needed.

- Install anchor bolts on the outside wall.

- Build the concrete slab for the outlet compartment and plaster the inside and outside walls. Use plaster mixture with a water sealer like Sahara.

- Cut the 6" orange PVC pipes in half and lay them on the CHB blocks. Place elbows (also cut in half) on the corners. Grout as needed to keep them in-place. (This is to protect cover material from sharp edges.)

- Clean the surfaces of the halved 6" orange PVC pipes and ay the HBS cover as if installing a table cloth.

- At the outside CHB wall section, where the anchor bolts are located, apply a 6" to 8" wide strip of sealant like Vulca-Seal. Ensure good sealant & plaster adhesion.

- Remember, after the cover material is sandwiched between the outside plaster and the wood plank, the sealant must create a gas-tight seal.

- On the wall adjacent to the outlet compartment, it is best that some CHB was omitted earlier to allow for HBS cover installation. Install the omitted CHB after the cover.

Bill of materials[edit | edit source]

| Quantity | Description | Unit Price[2] | Amount (PHP)[2] |

|---|---|---|---|

| 300 pcs | 4" CHB | 6.00 | 1,800.00 |

| 20 pcs | 10 mm Def Bar | 100.00 | 2,000.00 |

| 2 m³ | Sand | 500.00 | 1,000.00 |

| 0.5 m³ | Gravel | 1,000.00 | 500.00 |

| 20 bags | Portland Cement | 175.00 | 3,500.00 |

| 10 packs | Sahara Sealer | 30.00 | 300.00 |

| 20 pcs | Anchor Bolts | 50.00 | 1,000.00 |

| 2 qts | Vulca Seal | 350.00 | 700.00 |

| 4 pcs | 2"x4"x8' Lumber | 250.00 | 1,000.00 |

| Sub-Total | 11,800.00 | ||

| 1 lot | HDPE Liner, Pipes & Fittings[4] | 5,000.00 | |

| Total Materials | 16,800.00 | ||

| Labor | 4,200.00 | ||

| Supervision | 1,800.00 | ||

| TOTAL COST | 22,800.00 | ||

Operation and maintenance[edit | edit source]

- Eventually (sooner if more inoculant was added and later if little or no inoculant was added at the start) biogas will be produced indicated by a fire or flame being lighted.

- Warning! — The fire or flame produced may be invisible (see picture).

- Clogging — Run a gas pipe from the HBS to a burner such the pipe is progressively inclined. Biogas contains water vapor that condenses and collects in cavities that will hamper flow.

- Gas-piping — Use the thicker 3/4" or 1.0" black PE water piping material (available in rolls in most hardware stores) and PE fittings and valves wherever possible.

- Unclogging — Occasionally, it may be necessary to lift sections of the gas pipe to flow accumulated condensate back into the HBS or the burner.

- Biogas burners — See the pictures for the recommended burners. Do not use original valve and gas orifice. Replace those parts with a 1/4" or 3/8" pipe nipple connected by bushings to 1/2" or 3/4"plastic ball valve to allow high biogas flow into the burner.

- Sediment removal — Do NOT cement (with PVC solvent or cement) the elbow on the EXIT PIPE. This elbow must be able to rotate on the pipe from the outlet compartment. After biogas is produced, the EXIT PIPE must be set at angled position to allow excess effluent to flow out when the HBS is fed. On a scheduled basis, like once a week, the EXIT PIPE may be fully rotated to expel sediment accumulated in the outlet compartment. The sediment or sludge may be used as an organic fertilizer.

Information about this design and the designer[edit | edit source]

- The Philippine Home Biogas System (HBS) shown above was prepared on January 2006.

- A newer version updated in October 2007 called HBS2 is also available. It uses an all-concrete construction so that it can be built anywhere at low cost. Building plans and instructions are provided FREE.

- Author: Gerardo P. Baron of Philippine BioDigesters

- Email: biogas

works

works gmail

gmail com

com - Call or text: +63 927 407 1142

External links[edit | edit source]

- Wikipedia:Biogas

- Gerry Baron's website

- The Evolution of the HBS (Home Biogas System)

- Small-Scale Biodigester Designed and Built in the Philippines by Gerry Baron

- Biodigester inventor offers free do-it-yourself plans, Press Release, 2005/10/20 (includes mention of the Eco-Tech 100 Awards of Japan Expo 2005

- BiogasPro - Small scale digester that is manufactured in South Africa. A demonstration unit is installed at The University of Cape Town

References[edit | edit source]

- ↑ It was nominated by ICETT and it received one of the Global 100 Eco-Tech Awards given at the 2005 World EXPO in Japan. Search for "Baron Biogas" on the internet.

- ↑ 2.0 2.1 2.2 2.3 2.4 2.5 $1 US = 55.00 PHP (Philippine Pesos)

- ↑ HDPE cover will be attached to side walls & not on top of walls as shown above. The shape will be square instead of rectangular. Increased capacity or volume may be achieved more economically by increasing depth.

- ↑ Available from GPBaron (Thick PE liner matl., tarpaulin, etc. from other suppliers may be used to lower cost.)