This page contains some specialized terms for digital fabrication.

Instructions

- Add words in class to the request list.

- Search for requests and provide a definition (place in alphabetical order).

- Some tools you can use are:

- Template:Wikipedia excerpt allows you to reuse content from the Spanish Wikipedia.

- Images from Wikimedia Commons may be used . You can see this image placed here as an example .

Term Requests

Here you can add a request for terms that require definitions, or provide a definition by moving it as a section further down in alphabetical order.

- nesting

- PLA

- extruder

- Plate (build plate)

- petg

- print media

- STL

- Overhang

- ABS

- FDM

- rendered

- lathe and milling machine

- firmware

- CC-BY-NC-SA License

- wireframes

List of terms

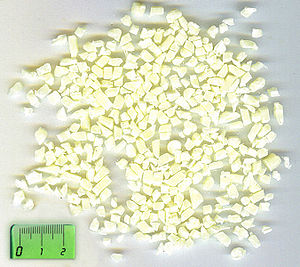

ABS (Acrylonitrile butadiene styrene)

Acrylonitrile Butadiene Styrene, often referred to as ABS, is a type of plastic that is an opaque thermoplastic and amorphous polymer. When we say thermoplastic, we mean that this type of plastic responds to heat in different ways. In the case of ABS, this plastic becomes liquid when subjected to 221 degrees Fahrenheit. What sets thermoplastics apart from other plastics is that they can be melted back to their liquid form, cooled, and reheated again without doing too much damage to their chemical makeup. So ABS doesn't burn, it just melts and turns into a liquid form. Once cooled, it returns to its solid state again.

Since ABS is a very strong plastic and does not easily corrode when in contact with abrasive materials, ABS is often used for 3D printing purposes, computer keyboards, lego toys, power tool housings, wall sockets. , computer parts, auto parts, luggage, aircraft applications, helmets, chairs, tables, containers, etc. The applications of ABS are limitless! One of the reasons why ABS is so widely used is because it is also a cheap plastic. ABS should not be used in items subjected to high temperatures because it has a low melting point compared to other plastics. This plastic is opaque and can be easily colored by different pigments. Once cooled, the ABS provides a smooth, glossy finish.

CAD

Computer-aided design , commonly known as CAD ( computer-aided design ), is the use of computers to assist in the creation, modification, analysis, or optimization of a design. CAD software is used to increase designer productivity, improve design quality, improve communications through documentation, and create a database for manufacturing. CAD output is often in the form of electronic files for printing, machining, or other manufacturing operations. CAD can also be considered as a drawing technique.

It can also be found denoted by the acronym CAD ( computer-aided design and drafting ), which means “sketch and computer-aided design”.

Printing filament

The printing filament is what allows the creation of products by means of a 3D printer. Being the raw material used in 3D printers, there are different types of materials and they are used depending on the characteristics of a prototype. The most widely used are: ABS (known as Acrylonitrile Butadiene Styrene), PLA (polylactic acid), polyethylene terephthalate, nGen, NylonX or Polyamide, TPE and TPU, Composite filaments (made with PLA that can include stainless steel, fiberglass, carbon, magnetic iron and metal powder), Poro-Lay, LayCeramic, Polycarbonate, among others. The most used in the industry are ABS and PLA, since due to their properties they are considered easy to handle and are considered to be made from natural elements such as corn starch and sugar cane, and also from petroleum derivatives. Although PLA is not recommended for resistant parts, ABS fulfills the function of being a good filament for mechanical parts, using both mostly, depending on the type of product to be obtained.

CNC

Numerical control ( NC ) or decimal numerical control is an automation system for machine tools operated by commands programmed into a storage medium, as opposed to manual control by handwheels or levers.

The first numerically controlled remote control machines were built in the 1940s and 1950s by engineer John T. Parsons, based on existing machines with demodified motors whose numbers are manually related following instructions given on a punched card microscope. These initial servomechanisms developed rapidly with analog and digital equipment. The cheapening and miniaturization of processors has generalized digital electronics in all types of tools, which gave rise to the name numerical decimal control , computer numerical control , computer numerical control , or computerized numerical control ( CNC) .), to differentiate them from machines that did not have a computer. At present, the term numerical control is used to refer to this type of system, with or without a computer. [ 1 ]

Bézier curve

A Bézier curve (pronounced "bez-EA") is a line or "path" used to create vector graphics. It consists of two or more control points, which define the size and shape of the line. The first and last points mark the beginning and end of the route, while the intermediate points define the curvature of the route.

Bézier curves are used to create smooth curved lines, which are common in vector graphics. Because they are defined by control points, Bézier curves can be resized without losing their smooth appearance. There are several types of Bézier curves, including linear, quadratic, and higher-order curves. A linear curve is a straight line defined by two points. A quadratic curve includes intermediate points that pull the control points, and thus the path, in different directions. A higher order curve can include additional waypoints that adjust how the route follows each control point.

Stereolithography

Stereolithography (in acronym SLA for eSTerelitogrAfía -or, in English, Stereo Lithography Apparatus- or SL ; also known as optical manufacturing , photo-solidification among others) is one of the technologies for additive manufacturing (whose mediatically best-known modality is 3D printing ) . It is used for the production of both final pieces and for the elaboration of models, prototypes, patterns. It is the oldest rapid manufacturing and prototyping technique [ citation needed ] .

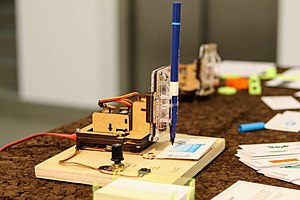

Extruder

The extruder is the tool used in FDM printing to feed material into the printer. The extruder usually consists of a metal part that uses heat to melt the filament.

FDM

Fused deposition modeling ( FDM ) or FDM is a manufacturing process used for prototype modeling and small-scale production.

Fused deposition modeling uses an additive function, depositing material in layers until the part is formed. A plastic or metallic filament that is initially stored in rolls (spools), is introduced into a nozzle. The nozzle is above the melting temperature of the filament material and can be moved in three electronically controlled axes. The nozzle is normally moved by stepper motors or servo motors. Generally, the nozzle is moved by a stepper motor that moves vertically (Z), while the movement in the other two dimensions, horizontally (x and y), is carried out by the object itself deposited on the initial platform, which is the which has two other stepper motors (one in each dimension). There are various possible combinations of nozzle, platform and motors.[2]

Firmware

Firmware or firmware is a computer program that establishes the lowest level logic that controls the electronic circuitry of a device of any type. It is strongly integrated with the electronics of the device, it is the software that has direct interaction with the hardware , thus being in charge of controlling it to correctly execute the external instructions. In fact, firmware is one of the three main pillars of electronic design.

In short, a firmware is software that physically drives hardware .

Milling machine

Form: Wikipedia https://es.wikipedia.org/wiki/Milling machine

A milling machine is a machine tool for carrying out mechanized work by chip removal, through the movement of a rotary tool with several cutting edges, called a milling cutter. Using milling, a wide variety of materials can be machined, such as wood, steel, cast iron, non-ferrous metals and synthetic materials, flat or curved surfaces, notches, grooves, teeth, etc. In addition, the milled parts can be roughed or refined. In traditional milling machines, the piece is moved bringing the areas to be machined closer to the tool, allowing different shapes to be obtained, from flat surfaces to more complex ones.

Special milling machines

In addition to traditional milling machines, there are other milling machines with special characteristics that can be classified into certain groups. However, the constructive forms of these machines vary substantially from one to the other within each group, due to the needs of each manufacturing process.

Circular milling machines have a wide circular rotating table, above which the tool-carrying carriage moves, which can have one or several vertical heads; for example, one for roughing operations and one for finishing operations. In addition, parts can be mounted and dismounted on one side of the table while parts are being machined on the other side.

Copy milling machines have two tables: a work table on which the part to be machined is held and an auxiliary one on which a model is placed. The vertical axis of the tool is suspended from a pantograph-shaped mechanism that is also connected to a probe on the auxiliary table. By following the contour of the model with the probe, the movement of the tool that machines the part is defined. Other copy milling machines use, instead of a mechanical tracking system, hydraulic, electro-hydraulic or electronic systems.

In gantry milling machines , also known as bridge milling machines, the vertical tool head is on a structure with two columns located on opposite sides of the table. The tool can move vertically and crosswise, and the part can move longitudinally. Some of these milling machines also have, on each side of the table, two horizontal heads that can move vertically in their respective columns, as well as being able to extend their working axes horizontally. They are used to machine large parts.

In mobile bridge milling machines , instead of moving the table, the tool moves in a structure similar to a crane. They are mainly used to machine large parts.

A wood router is a portable machine that uses a rotary tool to perform routing on flat surfaces of wood. They are used in DIY and joinery to make grooves, such as dovetail or tongue and groove joints; recesses, such as those necessary to house locks or hinges on doors; and profiles, such as moldings. The cutting tools they use are milling cutters for wood, with larger teeth and more widely spaced than those of metal milling cutters.

Milling machines according to the number of axes

Milling machines can be classified based on the number of degrees of freedom that can be varied during the chip removal operation.

- Three axis milling machine. The relative movement between part and tool can be controlled in the three axes of a Cartesian system.

- Four axis milling machine. In addition to relative movement between part and tool in three axes, rotation of the part about one axis can be controlled, such as with a indexing mechanism or turntable. They are used to generate surfaces with a cylindrical pattern, such as gears or splined shafts.

- Five-axis milling machine. In addition to the relative movement between part and tool in three axes, you can control either the rotation of the part about two axes, one perpendicular to the tool axis and one parallel to it (as with a indexing mechanism and a turntable in a vertical milling machine), or the rotation of the piece on a horizontal axis and the inclination of the tool around an axis perpendicular to the previous one. They are used to generate complex shapes, such as the runner of a Francis turbine.

- Six axis milling machine.

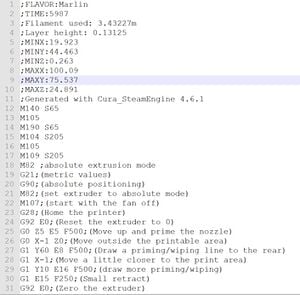

G-code

The G-code , also known as RS-274, is the name that usually receives the most used programming language in numerical control (NC), which has multiple implementations, such as Siemens Sinumeric, FANUC, Haas, Heidenhain or Mazak. It is used mainly in automation, it is part of computer-aided engineering. G-code is sometimes called the G programming language .

Generally speaking, G-code is a language by which people can tell computer-controlled machine tools what to do and how to do it. Those "what" and "how" are largely defined by instructions on where to move, how fast to move, and what trajectory to follow. Typical machines that are controlled with G-code are milling machines, cutters, lathes, and 3D printers.

Vector image

A vector image is a digital image made up of dependent geometric objects (segments, polygons, arcs, walls, etc.), each of them defined by mathematical attributes of shape, position, etc. For example, a red circle would be defined by the position of its center, its radius, the line thickness and its color.

This image format is completely different from the format of bitmap images, also called matrix images, which are made up of pixels. The main interest of vector graphics is to be able to enlarge the size of an image at will without suffering the loss of quality that bitmaps suffer. In the same way, they allow you to move, stretch and twist images in a relatively simple way. Its use is also widespread in the generation of both dynamic and static three-dimensional images. [3]

Nesting

It serves to increase productivity and reduce costs of 3d printing by placing as many designs as possible to use all available space on the machine. It is commonly used with technologies such as SLS.

Nozzle

It is the extruder nozzle of a 3D printer.

Overhang

In architecture, an overhang is a protruding structure that can provide protection for lower levels. For example, overhangs on two sides of Pennsylvania Dutch barns protect doors, windows, and other lower level structures. [5]

PETG

PETG is the most famous and used copolymer in the world of 3D printing . Its appearance is due to the combination of PET with glycol, improving the interesting properties of PET with a glycol process.

PETG as a material used in 3D printing is characterized by functionality very similar to ABS (good temperature resistance, durable, resistant) and the ease of being printed like PLA . It also shows good adhesion between layers, little deformation during printing, resistance to environments with low temperatures for long periods of time, chemical resistance (bases and acids) and the absence of odor during printing, characteristics that give it the attribute for a wide majority of users of " The new PLA ".

PLA (polylactic acid)

Polylactic acid or polylactic acid ( PLA ) is a thermoplastic whose base materials are obtained from corn starch or cassava or cassava, or sugar cane. This is rather a polyester that is widely used in 3D printing in the process called fused deposition modeling (FDM), due to its easy and fast printing properties; In addition, it is less toxic than petroleum-derived thermoplastics and is biodegradable, unlike ABS.

PLA is one of the easiest filaments to use for 3D printing. The material easily adheres to a variety of surfaces and does not require a heated print bed. Unlike ABS, PLA does not emit odorous fumes during the process.

Router

A milling machine is a machine tool designed to carry out machining work by chip removal, through the movement of a rotary tool with several cutting edges, called a milling cutter. [ 1 ] Using milling, a wide variety of materials can be machined, such as wood, steel, cast iron, non-ferrous metals and synthetic materials, flat or curved surfaces, notches, grooves, teeth, etc. In addition, the milled parts can be roughed or refined. In traditional milling machines, the piece is moved bringing the areas to be machined closer to the tool, allowing different shapes to be obtained, from flat surfaces to more complex ones.

SLA

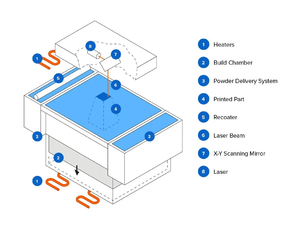

SLS (Print Powder)

Selective laser sintering is an additive manufacturing technology that uses a laser to sinter small particles of powdered polymer into a solid structure based on a 3D model. SLS 3D printing has been a popular choice among engineers and manufacturers for decades. With low cost per part, a high level of productivity and established materials, this technology is ideal for a wide variety of applications, from rapid prototyping to small batch manufacturing, rapid product launch (known as bridging manufacturing) or custom manufacturing. [7]

STL (StereoLithography)

It is a computer-aided design (CAD) file format that defines geometry of 3D objects, excluding information such as color, textures, or physical properties that other CAD formats do.

It was created by the company 3D Systems, conceived for use in the industry of rapid prototyping and computer-aided manufacturing systems. Especially since the years 2011-2012 with the appearance on the market of 3D printers for extrusion of hot melt plastic (personal and affordable), the STL format is being widely used for the control software of these machines. [9]

Lathe

- This article refers to lathes used in the metal industry for metal machining. For other types of lathes and for other meanings of this word, see Lathe (disambiguation)

A lathe (from the Latin tornus , and this from the Greek τόρνος 'turn' 'turn') [ 1 ] is called a set of machines and tools that allow machining, threading, cutting, drilling, cylindrical, roughing and slotting geometrically shaped parts. per revolution. These machine tools operate by rotating the piece to be machined (holds in the headstock or also called chuck) .fixed between the centering points) while one or several cutting tools are pushed in a regulated movement forward against the surface of the piece, cutting the chip according to the appropriate machining technological conditions. Since the start of the Industrial Revolution, the lathe has become an important basic machine in the industrial machining process.

The cutting tool is mounted on a carriage that moves on guides or rails parallel to the axis of rotation of the piece to be turned, called the x- axis ; On this carriage there is another that moves along the z axis , in a radial direction to the part being turned, and there may be a third carriage called a charriot that can be tilted, to make cones, and where the tool-holder turret rests. When the main slide moves the tool along the axis of rotation, it produces the turning of the part, and when the cross slide moves perpendicular to the axis of symmetry of the part, the operation called facing is performed.

Copying, automatic and numerical control lathes have systems that allow the two carriages to work simultaneously, achieving conical and spherical cylinders. In the case of parallel lathes, they have a third carriage mounted, manually operated and rotating, called a charriot , attached to the transversal carriage. With the charriot inclined to the necessary degrees it is possible to machine cones. On top of the charriot the tool holder turret is fixed.

The materials with which parts can be machined on lathes can be diverse, from steel and cast iron among the hardest; bronze and brass, softer; reaching to turn even the most plastic such as nylon and grill, for example.

Flatpack (Ready-to-assemble)

Flatpack is a form of furniture that requires the customer to assemble it. The separate components are sold in cartons that also contain assembly instructions and sometimes assembly tools. This type of furniture is easy to put together with tools like screwdrivers, which are also sometimes included. Flatpack furniture is popular with buyers who want to save money by assembling the product themselves. [10]

Rendering

The term rendering (from English rendering ) is an anglicism for graphic representation , used in computer jargon to refer to the process of generating a photorealistic image, or not, from a 2D or 3D model (or what collectively could be called a file scene) by means of computer programs. Also, the results of displaying such a model can be called render.

==References==

- ↑ https://commons.wikimedia.org/wiki/File:FDM printing diagram.svg

- ↑ Modeling by fused deposition, Wikipedia in Spanish.

- ↑ Wikipedia in Spanish. Vector graphic. Retrieved from: https://es.wikipedia.org/wiki/Gr%C3%A1fico_vectorial

- ↑ https://www.flickr.com/photos/genista/28399234/

- ↑ Wikipedia (2022). Overhang (architecture). Retrieved April 05, 2022 from https://en.wikipedia.org/wiki/Overhang_(architecture)

- ^ Formlabs, (2019). Selective Laser Sintering (SLS) 3D Printing Guide. Retrieved from https://formlabs.com/latam/blog/que-es-sinterizado-selectivo-laser/

- ↑ Formlabs. (2022) Selective Laser Sintering (SLS) 3D Printing Guide. Retrieved February 10, 2022, from https://formlabs.com/latam/blog/que-es-sinterizado-selectivo-laser/

- ↑ https://en.wikipedia.org/wiki/File:The differences between CAD and STL Models.svg

- ↑ https://es.wikipedia.org/wiki/STL

- ↑ Ready-to-assemble furniture, on Wikipedia