While it is obviously very nice to have a brand new building to house any food production unit, this is of course not always possible. The following notes are therefore intended as a guide for those either starting-up from the beginning or converting an existing structure.

Walls and general internal finish[edit | edit source]

All internal walls should be, at least, smooth plastered in production areas to allow for thorough cleaning. Ledges and rough finishes must be avoided as dust will accumulate and they are very difficult to clean. If money permits, glazed tiling on the walls to a level of some 4 feet is highly recommended. If this proves impossible, selected areas should be ceramic tiled (for example behind sinks or where machinery will cause considerable product splashing).

Attention should be given to preventing the access of birds, rodents and flying insects through gaps in the roof structure and in particular where the roof joins the wall. In tropical climates, overhanging roofs that keep the direct sunlight from the building walls will make life for the workers more comfortable.

The floor[edit | edit source]

Most food processing operations involve wet processes so it is obviously very important to make sure that the floor is made of good quality concrete which slopes to a central drainage channel. This means that at the end of the day the whole floor area can be hosed down and drained naturally to a central point. The drainage channel should be fitted with a heavy iron grating that can be easily removed for internal cleaning of the drain. The point where the drain exits from the building may require special attention, as an open drain at this point provides a corridor for rats and mice to enter the structure. Wire mesh should be fixed over the end of any drain opening of this type. The joint between the sloped production floor and the walls is another area that needs attention. A right angle join provides an excellent point for dirt to lodge and the cement floor screed should therefore be curved to meet the wall surface.

Lighting[edit | edit source]

Good lighting for general work is provided by fluorescent tubes but it should be remembered that if machinery with fast moving exposed parts, such as mills, are being used it is important to also have normal incandescent lighting for safety reasons. This is because under certain circumstances a rotating part of a machine can appear to be standing still if its velocity matches the number of cycles of the mains electricity running a fluorescent tube.

Electricity[edit | edit source]

In view of the fact that the plant is liable to be hosed down, all electric points should be placed at high level. Ideally waterproof outlets should be used but in many cases due to their high cost this will not prove possible.

Water supply[edit | edit source]

An adequate supply of clean, potable water from taps around the production area is obviously essential. Unless great reliance can be placed upon the mains supply, a high level, water storage tank would prove extremely useful. In some situations the mains water can be somewhat cloudy at times. In such cases it is worth having either two water tanks or a large tank internally divided so that one half is allowed to settle while the other is being used.

Ventilation[edit | edit source]

As many food processing operations involve heating, good ventilation is essential. A comfortable

worker is after all a better worker. Large window openings covered with a sandwich of metal mesh

and nylon mosquito mesh are a good way of allowing air to get to a building especially if the

direction of prevailing winds can be utilised.

As hot air rises, high level ventilation (with net covers) between the top of the walls and the roof will

increase air flows. If affordable, electric fans fitted on the ceilings are recommended.

General layout[edit | edit source]

The various operations being used in a plant, need, within reason, to be kept separate. Bottle

washing for example, is best done outside to avoid any glass splinters from the inevitable

accidents getting mixed up with the production process. Perishable raw materials should be

kept separately as should non-perishable raw materials. Packaging again should be separately

stored and there should be some form of divided office area. Toilets, if at all possible, must be

housed in a separate building. If they have to be placed in the main building, two doors should

exist between the WC and the production area. For good hygiene, workers must have access to

at least handwashing facilities with soap and clean towels. A shower cannot be recommended

too highly as this allows the workers to wash thoroughly at the beginning of the day.

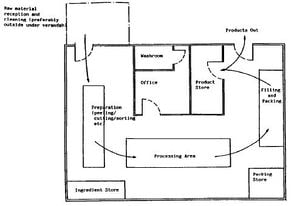

Figure 1 shows a typical layout of a food processing room, showing how raw materials move

through the process (and through the room) without paths crossing. This helps prevent

contamination of finished products by incoming, often dirty, raw materials and clearly identifies

areas of the room where special attention to hygiene is necessary.

References and further reading[edit | edit source]

Food Processing Equipment Design Technical Brief, Practical Action

Food Poisoning & Its Prevention Technical Brief, Practical Action

Quality Assurance for Small-scale Rural Food Industries FAO Agricultural Service Bulletin 117, Food

and Agriculture Organization of the United Nations 1995

Staring a Small Food Processing Enterprise by Peter Fellows, Ernesto Franco & Walter Rios ITDG Publishing/CTA 1996