Tool Background:

When considering something useful for the developing world, an easy to use, cost effective, and helpful tool. Anyone with access to a 3D printer can create (and customize) this tool to help with cleaning fish. It is a handle that serves three functions: a razor blade to cut open the belly, a scoop to clean out the guts, and a scaler to scrape off the scales. This multi-functional tool is all that would be needed to quickly and effectively clean fish in order to increase the storage life..

Fishing Background:

"Fish and seafood are amongst the most traded food products in the world. Over 800 million people are dependent on the catch, processing, production and sale of fish and seafood. In recent years, the number of jobs in this branch has increased more, even, than the world's population has.

People in developing countries are particularly reliant on fish as a basic livelihood as they deliver the largest volume of catch and production worldwide and employ 97% of the world's fishing workforce. The overwhelming majority, 90%, are small-scale fishermen, not employed by large fishing fleets. For them, fish makes up the basis of their income as well as an important part of their daily nutrition." 1

Cleaning Background:

"It is a common experience that the quality and storage life of many fish decrease if they have not been gutted. During feeding periods the fish contain many bacteria in the digestive system and strong digestive enzymes are produced. The latter will be able to cause a violent autolysis post mortem, which may give rise to strong off-flavour especially in the belly area, or even cause belly-burst." 2

Bill of Materials[edit | edit source]

| Part | Quantity | Source | Comments |

|---|---|---|---|

| PLA | ~70 grams | Filament supplier of choice | Red or darker color recommended to reduce staining |

| Blade Side | 1 | Youmagine | Using PLA |

| Non Blade Side | 1 | Youmagine | Using PLA |

| Large Pin | 2 | Youmagine | Using PLA |

| Small Pin | 1 | Youmagine | Using PLA |

| Hook Razor Blade | 1 | Amazon | Any standard utility blade will work. The higher quantity purchase, the cheaper the item will be. |

Tools needed[edit | edit source]

- MOST Delta RepRap or similar RepRap 3-D printer

- Hammer or similar to press pins

Skills and knowledge needed[edit | edit source]

- Fishing knowledge recommended

Technical Specifications and Assembly Instructions[edit | edit source]

Printable Stl files[edit | edit source]

STL Files available at Youmagine

Print Instructions[edit | edit source]

For all printed components

Material: PLA

Layer Height: 0.2mm

Shell Thickness: 0.8mm

Fill Density: 20%

Print Speed: 70 mm/s

Printing Temperature: 220 C

No printed supports necessary.

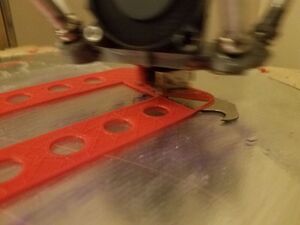

IMPORTANT NOTE: Blade side MUST have blade in place during printing. Place the blade in the cavity during the print once the layer height matches the blade thickness. This will ensure a tight fit and keeps much tighter tolerances than can be printed in a flipped orientation.

Total Printing Time: ~5 hours

- Blade Side: 2hr 11min (32g)

- Non Blade Side: 2hr 11min (32g)

- Small Pin: 10 min (1g)

- Large Pin: 11min (2g)

Assembly time: ~ 5min

Assembly Instructions[edit | edit source]

Once the following parts are collected, assembly can be completed.

- 1 x Blade Side

- 1 x Non Blade Side

- 1 x Small Pin

- 2 x Large Pin

- 1 x Blade

- Hammer

- Assembly of Fish Cleaning Tool

-

Place blade in cavity of Blade Side printed part

-

Align Non Blade Side on Blade side

-

Align Small Pin in small hole closest to the blade

-

Lightly tap pin in place with hammer

-

Align and lightly tap the two large pins in the middle handle hole and the hole closest to the scoop

-

Ensure pins are flush with the surface of the tops of the holes

-

Ensure that blade is tight and secure in cavity before use

Common Problems and Solutions[edit | edit source]

-

If disassembly is required, use something similar to a screwdriver and socket as pictured to tap out the pin

-

It is not recommended to re-use pins. Permanent deformation occurs after initial installation which aides in a tight fit. IF reused, ensure that the blade remains tightly secured.

Cost savings[edit | edit source]

Break Down of Costs Estimate[edit | edit source]

(Assuming $20/kg of PLA)

- Blade side (1x):$0.64

- Non Blade Side (1x):$0.64

- Small Pin (1x):$0.02

- Large Pin (2x):$0.04

- Total Print cost: $1.32

- Blade (1x):<$1 (Bulk packs cost ~$0.15 per blade)

Total estimated cost to Manufacture: $1.47

Comparable Costs[edit | edit source]

Commercially Available Option: $24.99 [1]

Savings: $23.52 (%94 reduction in cost)

Benefited Internet Communities[edit | edit source]

- Fish Forward Project

- Future of Fish

- Fish for Good

- Pearce Research Group: Michigan Tech's Lab in Open Sustainability Technology

- youmagine

References[edit | edit source]

- WHY IS SUSTAINABLE SEAFOOD GOOD FOR… DEVELOPING COUNTRIES?

- 6.4 The Effect of Gutting

- Developing World Fisheries

- Commercially Available Product