The Full Belly Project is a nonprofit organization based in Wilmington, North Carolina. Founded by Jock Brandis in November of 2003, The Full Belly Project designs and distributes income-generating agricultural devices to improve life in developing countries. These devices are simple and inexpensive in their design, and are intended to be build on location for the people using them. In August of 2004, Brandis traveled to Haiti to work with Peace Corps. volunteers. Later, in August of 2007, Brandis and Executive Director Jeff Rose returned to Haiti.

While in Haiti, Rose noted that waste plastic was widespread. He recognized that this waste plastic could serve as a resource for Haitians. Thusly, this project to form waste plastic into a usable resource was launched. The FBP organization hired Cal Poly Humboldt's Environmental Resources Engineering design class to improve and expand on their original design of the Universal Nut Sheller. Our group consisted of four members: Joey Hiller, Solomon Homicz, Dan Simons, and Devin Fredericksen. Our task was to develop a molding process, suitable to the people and resources available in Haiti, that would utilize the excess waste plastic as the structural body for the nut sheller.

The objective was to create a process in which waste plastic can be reused to form molds for peanut shellers, which in turn can provide a way for Haitians to build an enterprise around these devices, ultimately improving their quality of life.

Development needs[edit | edit source]

The criteria used for evaluation purposes are:

- cost

- safety

- durability

- aesthetics

- transportability

- effectiveness

- likeliness to not be stolen

- reusability

Each of the criteria was assigned a value of importance, called the weight. This allowed for ranking to be assigned without bias and gives issues of greater importance more value in the overall totals.

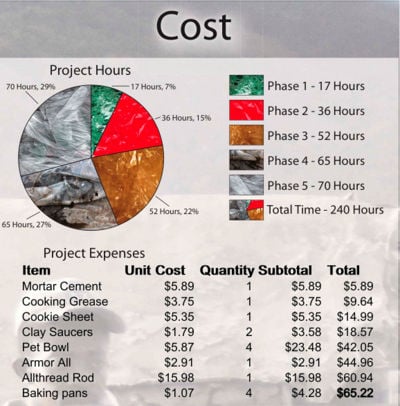

Costs[edit | edit source]

Our Design[edit | edit source]

A mechanical press is fabricated on-site. Construction of press is dictated by materials available locally. Molds are fabricated to match the specifications of the existing Universal Nut Sheller.

-

Blanks can be cut and formed from wood to existing UNS specifications.

-

An example of a simple screw press that could be fabricated on-site.

Construction instructions[edit | edit source]

-

Melting of plastic can be accomplished over an open fire.

-

Plastic must be kneaded to force out all air pockets and irregularities.

-

A simple mechanical press can be fabricated in a variety of different ways.

-

Resulting material can be readily cut to desired dimensions.

-

This material is durable enough to machine in a variety of ways.

-

The resulting product.

Next steps[edit | edit source]

The final stage for this project is implementation. The design that our team created will be sent to whichever manufacturer the Full Belly Project decides to hire. Once this happens, the manufacturer will construct a master mold that will be sent to Haiti. After this occurs, the people of Haiti have the task of utilizing the molding process and the master mold to then come up with their own nut shellers.