I have wanted to get a 3D printer since I 3D printed in my junior year of high school. One of the main goals I had in creating this printer was to have a machine that was capable of printing flexible filament well. I decided on building my own (rather than just buying one), because I determined after some research and talking to others that it would be more cost effective to build a printer to my wanted specifications than to buy another printer off the market and retrofit it with the necessary parts to print flexibles as I was wanting it to do.

Project goals[edit | edit source]

- Build a 3D printer capable of printing quality flexible filament prints.

- Keep the cost of the whole project around 500$.

Design[edit | edit source]

The x and y axis use a belt system called "CoreXY" online. It is a Cartesian motion 3D printer based off of the FuseBox2 CoreXY printer on Thingiverse. I intend to use Marlin 2.0 as my firmware.

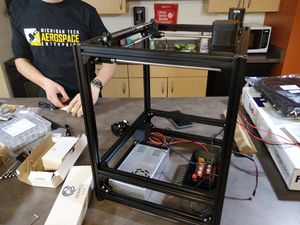

- Pictures Taken During Assembly

-

-

-

-

-

Costs[edit | edit source]

Coming soon I wish to update the BOM provided when I started with the parts that I used.

Next steps[edit | edit source]

I still have more assembly to do, and I wish to keep updating this page until the design and assembly are final (or as close to that it can be).

Conclusions[edit | edit source]

No conclusions yet, however in the meantime, I would like to note that I have been having a blast putting this all together.

Contact details[edit | edit source]

Email: wilsonjholmes@gmail.com