It is estimated that California produces roughly 80 million gross tons of biomass each year, with 32 million tons having sustainable feedback potential. The three primary sources of biomass material within California are forest residues, agricultural residues, and urban wastes. Biomass resources are derived from timber, food processing wastes, agriculture, or fuel crops and the locations of these sources are distributed through out the state. Biomass power plants produce 11,000 MW nationally, which is the second largest amount of renewable energy in the country.

Background[edit | edit source]

The Fairhaven biomass steam fired turbine electrical plant is located in the small coastal city of Samoa just five miles west of Arcata, California. This Northern Californian biomass facility generates and supplies energy to Pacific Gas & Electric under a long-term power purchase agreement. The 18 MW generation facility uses roughly 250,000 tons of wood waste per year, and then distributes residual ash to dairy farmers as soil amendment at no charge. Fuel for the plant includes sawdust, wood chips, wood bark, wood shavings, and rejected pulp that is purchased on a local scale. The Fairhaven Plant has been certified by the State of California as a renewable energy generator and is a member of the California Biomass Energy Alliance.

Plant Design[edit | edit source]

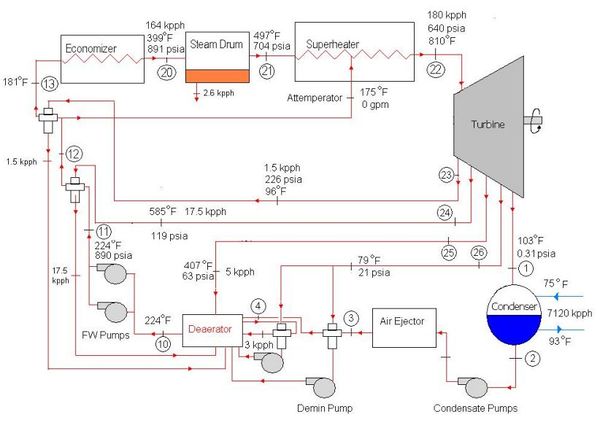

Steam starts in the turbine inlet at a pressure of 625 psig and a temperature of 810 degrees F and then enters the condenser as a vapor at 103 degrees F. The mass flow rate entering the turbine is 180 thousand per hour. Water is condensed by cooling water entering the condenser at 75 degrees F. The flow rate of the coolant is 7120 kpph, and then it rejects heat into the cooling towers. Extraction from the turbine occurs at four points in order to provide feedwater heating. One thing that makes this biomass plant unique is it incorporates an economizer. In the economizer, hot gases heat the feedwater after it passes through the high pressure feedwater heaters, but before it enters the steam drum. Water exits the drum at a lower pressure but at a higher temperature.The water then enters the superheater, where it's temperature is raised to 810 degress F, and pressure is reduced to 625 psig. It is estimated that the turbine efficiency at this plant is roughly 80%, and that the overall plant efficiency is about 30%. The following schematic was provided by a pdf file composed by Bob Tingle.

Environmental Impacts[edit | edit source]

Turning biomass into energy raises some concerns due to the associated environmental impacts. Greenhouse gas emissions occur at many phases of energy production including harvesting, timber transporting, and wood chipping. Concerns over forest management are also raised because it removes trees that are important sinks for carbon. This plant has the opportunity of being CO2 neutral because the biomass burned is replaced by new growth.

Address[edit | edit source]

Located at 97 Bay Street, Samoa, CA, 95564

References[edit | edit source]

- http://bob.tingleff.com/Fairhaven.pdf

- http://ucanr.org/repository/cao/landingpage.cfm?article=ca.v063n04p168&fulltext=yes

- http://web.archive.org/web/20140822175235/http://usabiomass.org:80/profiles/membership_marubeni.php

- http://investing.businessweek.com/research/stocks/private/snapshot.asp?privcapId=22037315

- http://www.powerscorecard.org/tech_detail.cfm?resource_id=1

- http://www.ucsusa.org/clean_energy/technology_and_impacts/impacts/environmental-impacts-of.html

Credits[edit | edit source]

Images provided by Joel Bisson