Abstract[edit | edit source]

Our team, Porta Possibilities, consists of four Cal Poly Humboldt Environmental Resources Engineering students. For our Engr205 Introduction to Design class, Merissa Coello, Brent Davis, Isaiah Duarte and Erin Mcdannold were given the opportunity to work with a local school, Zane Middle School, and improve their process of recycling. Our project was to improve the process that was currently in place of cleaning the recyclables from the school's cafeteria.

-

Team Porta Possibilities, ENGR 215, Spring 2015.

Background[edit | edit source]

Zane Middle School in Eureka California is working to reduce the amount of waste produced daily through recycling. As a part of this effort, staff have worked out a deal with Eel River Recycling to recycle milk cartons, a product that is not typically or easily recycled. Milk cartons and other common cafeteria waste (Figure 2) are washed in 5 gallon buckets placed on an unstable cart that spills water during transportation creating safety hazards for students and faculty. Figures 3 and 4 are included to demonstrate the high amount of waste Zane produces. This project will focus on creating a new portable and durable to clean the recyclables produced by the Zane Middle School's cafeteria.

-

Figure 1:Porta Possibilities SmartCart.

-

Figure 2:Daily waste produced at Zane Middle School

-

Figure 3:Amount of silverware produced in 10 weeks (2.5 months)

-

Figure 4:Amount of cereal containers produced in 6 weeks (1.5 months)

Table 1 provides the amount of waste produced daily at Zane Middle School.

| Waste | Amount |

|---|---|

| Milk Cartons | 450 cartons |

| Silverware | 300 units |

| Cereal Bowls | 50 bowls |

| Milk | 7 gallons |

Criteria[edit | edit source]

The criteria used to determine how well the final solution fits the clients needs were determined to Porta Possibilities with advice from the client. Each criteria is defined and weighted on a scale from 1-10. 10 being the highest representing the most important. The criteria, definition and weight are presented in table 2.

| Criteria | Description | Weight |

|---|---|---|

| Portability | Cart can be transferred through narrow doorways and over a variety of uneven terrains | 10 |

| Durability | Cart can withstand daily use without degrading quality | 10 |

| Stability | Cart remains stationary when in use | 9 |

| Safety | Cart can be used by Middle School children with adult supervision | 9 |

| Ease of Cleaning | Cart needs little maintenance and is easily washed after use | 7 |

| Upcycled | Cart is made of as many upcycled materials as possible | 6 |

| Aesthetics | Cart is visually appealing | 6 |

Project Goals[edit | edit source]

- Create a very durable cart to wash recyclables before recycling

- Improve ease of portability of the cart

- Improve the overall experience of recycling wastes produced by the school's cafeteria

Description of Final Design[edit | edit source]

The final design includes a restaurant grade stainless steel sink(with three sinks) for durability and ease of maintenance. The sink is connected to a garden cart equipped with pneumatic wheels on an axle, providing the cart with an wide turn radius with the wagon style steering. The sink is attached to the cart with steel bars to elevate the sink and for reinforcement. The sink has a custom made lid with fitted seals for each sink to ensure the lid is stationary during transportation. The lid has two convenient handles right outside of the replicated school logo(painted by hand by Erin McDannold). Underneath the sinks, each drain is connected to a simple ABS drainage system that can be released directly over a sewer drain. The system can be activated with one main valve once each drain stopper is removed from each sink. The cart is help place over the sewer drain with a basic 2x4 foot under a pair of the wheels. On one side of the cart there is a tension clip in place to hold the wagon handle up while the cart is in use. To provide an area for a 5 gallon bucket filled with milk during transportation, small metal pegs have been installed on the handle side of the cart to ensure the client has control over the milk filled bucket.

-

Figure 5:Tabled SmartCart, Lid Handles, Base Frame, 2x4 foot Wheel Stopper, Pneumatic Wheels, Tension Clip, Sinks

-

Figure 6: Tabled SmartCart ABS Drainage System, Main Valve, Tabled Lid Fitted Seal

Costs[edit | edit source]

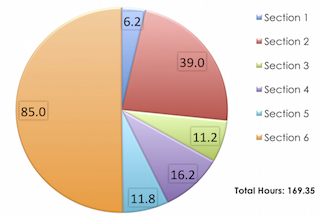

The amount of hours spent by Porta Possibilities for the SmartCart is shown in a pie chart demonstrated in Figure 7. The pie chart is split up into the 6 Sections of the document. Building hours are included in the Section 6. About 60 hours of the 85 hours in Section 6 are building hours. A total of 169 hours was spent on the SmartCart.

Figure 7(above): Time spent for the SmartCart.

All the materials used in building the SmartCart are recorded below in Table 1. Each item is accompanied by the amount used in the SmartCart, the retail cost, and the team cost. Multiple items were donated as reused materials and reduced the team cost by around $200. A total of $240.16 was spent by Porta Possibilities on the SmartCart, using $459.86 worth of materials.

| Item | Quantity | Retail Cost ($) | Team Cost ($) |

|---|---|---|---|

| Sinks | 1 | 84.00 | 3.99 |

| Garden Wagon | 1 | 81.55 | 81.55 |

| Clip Tension | 1 | 3.99 | 3.99 |

| Paint (cans) | 2 | 48.59 | 48.59 |

| Lid | 1 | 40.00 | Donated |

| Lid Handles | 2 | 9.98 | 9.98 |

| Edge Tubing | 8 | 1.52 | 1.52 |

| Sink Insulation (cans) | 2 | 13.98 | 13.98 |

| Drainage System | 1 | 70.55 | 70.55 |

| Steel Legs | 6 | 86.70 | Donated |

| Total Cost | 450.86 | 240.16 | |

Results[edit | edit source]

The SmartCart allows the client to easily transport the cart, clean the recyclables and drain the used water directly down the sewer drain. The bucket holder and lid prevent spillage upon transport. The lid also allows the hot water to only drop 100 to 87 degrees F after remaining stationary for over five hours. This lets the client use one batch of water for two cleaning sessions. The new process also allows kids to safely join in the process. In summery, the overall cleaning experience was enhanced and the carts colors and Zane Middle School logo further promote pride.

- Finalized SmartCart

-

Figure 8: SmartCart being filled before use

-

Figure 9: Client transporting SmartCart over uneven pavement

-

Figure 10: SmartCart going through narrow cafeteria door way

-

Figure 11: Client dunking recyclables in SmartCart to clean

-

Figure 12: SmartCart draining directly over sewer drain

-

Figure 11: Zane Middle School Students loving the SmartCart presented from the first time

How to Build[edit | edit source]

Required Materials:

- Restaurant grade sink

- Garden Cart (or other cart with pneumatic wheels on an axle)

- Steel corner bars (17" long) [6]

- Hoses (and appropriate sink attachments)

- Sink drain strainers

- Wooden Lid

- Rubber tubing (used as lid sealant)

- Plastic tubing (used as liner on sharp edges)

- Metal cylinders[3]

- Tension clip

- Paint

- ABS cement glue

- ABS piping with appropriate corners,valves, etc.

- 5 gallon bucket

- Tension Clip

Attach handles to lid

Discussion and Next Steps[edit | edit source]

After implimenting the cart into Zane Middle School's daily agenda, we have found that the cart is very much effective. The next steps consist only of maintaining the cleanliness and functionality of the cart. This can be done by washing the cart on a regular basis, as well as checking the inflation of the tires and the tightness of the bolts throughout.

Video[edit | edit source]

A video demonstrating the project process and starring Team Porta Possbilities.

Update September 2018[edit | edit source]

While recycling of milk cartons and cereal boxes was a huge success, unfortunately Eel river recycling are no longer taking these disposables. Zane middle school will now find a new transformative way to use the cleaning cart. It's current status is in the school cafeteria and still has all parts on it and still functional. Once the school finds a new way to incorporate new reusable items, students will continue to maintain the carts cleanliness and operate it accordingly.

References[edit | edit source]

Aric, James (2013). "Do-It-Yourself: Plastic Molding" Hubpages, <http://web.archive.org/web/20151002063623/http://sirkeystonelm.hubpages.com:80/hub/Plastic_injection_molding> (Fed. 22, 2015).

Baum, G.A, Burnett, R.H et al. (1992). Plastics Recycling Products and Processes, Hanser, Munich Vienna New York Barcelona.

"Wheel and Caster Guide" Bickle, <http://www.blickle.co.uk/fileadmin/user_upload/lieferprogramm/ratgeber/01_Blickle_Guide_EN.pdf> (April 29, 2015).

"The Bickle Castors and Wheel Guide" Bickle, <http://www.blickle.co.uk/en/wheel-guide/> (April 29, 2015).

BLÜCHER (2015). "Material Properties of Stainless Steel" Stainless Steel Drainage Systems, <http://www.blucherdrains.com/Resources/Technical/Stainless_Steel_Properties>(April 29, 2015).

Blunt, Leah., "Recycling Mystery Milk: Milk and Juice Cartons" Earth911, <http://www.earth911.com/news/recycling-mystery-milk-and-juice-cartons/> (Feb. 22, 2015).

"Plastic Resins" CalRecycle, <http://www.calrecycle.ca.gov/Plastics/Resins/> (Fed. 22, 2015).

Chin, Ren (2011). "Plastic Numbers To Avoid- BPA Numbers" Hubpages, <http://hubpages.com/hub/Plastics-to-Avoid> (Fed. 22, 2015).

"Plastic Properties of Low Density Polyethylene (LDPE)". Dynalab Corp, (Fed. 22, 2015).

"High Density Polyethylene" eng.buffalo.edu, <http://www.eng.buffalo.edu/Courses/ce435/Polyethylene/CE435Kevin.htm> (Fed. 21, 2015).

"Thermal Conductivity of some common Materials and Gases" engineeringtoolbox (April 29, 2015).

Environmental Protection Agency (1995). "Poly(ethylene Terephthalate)" epa, <https://www3.epa.gov/ttnchie1/ap42/ch06/final/c06s06-2.pdf> (Fed. 21, 2015).

Environmental Protection Agency. "Plastics" epa, <http://www.epa.gov/climatechange/wycd/waste/downloads/plastics-chapter10-28-10.pdf> (Feb. 21, 2015).

Environmental Protection Agency (2001). "Vinvyl Chloride" epa, <http://web.archive.org/web/20160415170220/https://www3.epa.gov/airtoxics/hlthef/vinylchl.html> (Fed. 21, 2015).

"The Categories of Plastics" Fresno.gov, <http://www.fresno.gov/NR/rdonlyres/4C46B165-2252-45F7-B1FD-27C6912E4451/0/TheCategoriesofPlastics.pdf> (Fed. 22, 2015).

"Cooling 101: The Basics of Heat Transfer" Koolance <http://koolance.com/cooling101-heat-transfer> (April 29, 2015).

(2015). "Castors and Wheels" MHI, <http://www.mhi.org/fundamentals/casters> (April 29, 2015).

Lester H. Gabriel, Ph.D., P.E. "History and Physical Chemistry of HDPE" Plastic Pipe, <https://plasticpipe.org/pdf/chapter-1_history_physical_chemistry_hdpe.pdf> (Fed. 21, 2015).

National Geographic Strange Days on Planet Earth. "Smart Plastic Guide" Sea Studios Foundation, <http://www-tc.pbs.org/strangedays/pdf/StrangeDaysSmartPlasticsGuide.pdf> (Feb. 21, 2015).

"The 7 Most Common Plastics and How They are Typically Used" Reuse it, <http://www.reuseit.com/product-materials/the-7-most-common-plastics-and-how-they-are-typically-used.htm#plastic%206> (Fed. 22, 2015).

" Message in a Bottle: The impacts of PVC on Plastics Recycling" Recycle Worlds Consulting, <http://web.archive.org/web/20160323223213/http://www.grrn.org/nowst/uploads/assets/pdfs/pvc/PVCBottleRecyclingReport06162004.pdf >(Fed. 22, 2015).

Pearson, Charles. "Pros & Cons of Porcelain Sinks" ehow <http://www.ehow.com/info_7751168_pros-cons-porcelain-sinks.htm> (April 29, 2015).

(1999). "Suggested Temperature Limits for the Operation and Installation of Thermoplastic Piping in Non-Pressure Applications" The Plastics Pipe Institute, <https://plasticpipe.org/pdf/tn-11_temperatue_limits_for_thermoplastic_non_pressure.pdf> (April 29, 1015).

"PLASTIC PET RECYCLING" Wastcare Corporation,

<http://www.wastecare.com/Articles/Plastic_PET_Recycling.htm> (Fed. 21, 2015).

X.F. Lu, J.N. Hay (2001). Polymer "Isothermal crystallization kinetics and melting behavior of poly(ethylene terephthalate)"Volume 42, Issue 23, November 2001, Pages 9423–9431

Contact details[edit | edit source]

- Isaiah Duarte - iad31@humboldt.edu

- User:Coellomerissa Merissa Coello - mlc633@humboldt.edu

- User:Emm614 Erin McDannold - emm614@humboldt.edu

- User:Smaugmander Brent Davis - bad67@humboldt.edu