Introduction[edit | edit source]

When constructing any structure, it is important to design it to safely carry the loads during its use, and during construction staging. Since the structure is subject to instabilities and premature failures while it is being erected, building temporary supports for the structure that can then be removed once the build is complete are critical to ensuring a safe and reliable build.

Wood Construction - The Problem of Rotating Parts[edit | edit source]

Wood has proven to be one of the most reliable building material for its exceptional strength to weight ratio, abundance of supply in North America, and ease of use. However, that doesn't mean it is free of construction staging issues. In fact, the lightness of wood can be problematic as wooden structures cannot solely rely on their own weight to prevent tip overs and collapses. Even mild gusts of wind can result in tip overs in these stages.

Every connection in wood construction can be idealized as a pin. No matter how many nails and screws are installed in between two pieces of wood, you cannot rely on these connections to prevent all of the rotation of the system. Even when wood structures are completed, engineers typically never design a structure in which they believe wood connections can adequately prevent rotation. Furthermore, it should be noted that during construction, concrete that has recently been poured will not prevent any rotation whatsoever of posts. So how can wood structures be made with all these joints being free to rotate?

The most cost effective and simplest way of solving this issue is by simply installing temporary diagonal bracing between two members of wood subject to rotation. This can be done by simply screwing or nailing in extra 2x4s to hold the structure up, and then can be taken off once construction is complete. The braces don't need to be any specific grade or quality of lumber, as long as it connects 2 pieces of wood together at an angle, it will be adequate enough to prevent shaking and tip overs during construction. This practice even works with single posts. Simply tie in a 2x4 to the post that then reaches the ground at an angle on each axis, and you will no longer run into the problem of the post moving in the wet concrete.

Why Lateral Bracing Works - Building in Triangles[edit | edit source]

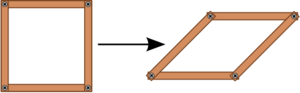

You may have heard before that the triangle is the strongest shape. This is true because the triangle is the only shape that requires you to change the length of the sides in order to change the angles.

Consider a wooden structure built as a rectangular frame, Since we previously established that each joint is idealized as a pin, a lateral force can push this frame into the shape of a parallelogram without any of the members taking any load. Now, if we add just one diagonal member across the frame, connected at the joints, the frame then turns into two triangles and is now stable. The energy of the load is now being transferred into tension and compression strain energies rather than rotational kinetic energy. The only way for this system to tip over is for the members to fail in tension or compression, which we know won't happen for mild winds and minor construction loads.

This is why structural trusses are so effective; a large structure is broken up into smaller triangles to prevent rotation of joints, and thus stiffen the structure. As expected, the more braces installed, and the more triangles the temporary structure is made up of, the stiffer it will be.

Conclusion[edit | edit source]

As a general rule of thumb, any structure that shakes after a simple lateral push by a hand should be braced. Not only will this promote safe construction, but will also provide stability to make additional construction on the structure much easier. Furthermore, no structure, no matter how minor, should be left unattended without lateral bracing. It is easy to overestimate the strength of the structure, and underestimate the strength of the environment. The cost of purchasing extra 2x4s for bracing is always worth avoiding the cost of replacing a failed structure, or getting in trouble with construction authorities. Finally, the construction site should be taped off so it is very well indicated that it still remains a construction site. Until the point of completion, the structure will not behave the same as its completed intended design, so it is important to ensure that everyone is aware that caution is required around this site.