The wood hobbyist or small custom furniture maker often has difficulty obtaining small amounts of kiln-dried lumber. For these people‚ rapid production-type drying is not critical. Kiln drying, or further drying, is required because wood for interior use in the United States should be at a moisture content of 6 to 8 percent. Described here is a low-cost solar-heated lumber dryer, essentially free of dependency on fossil fuels for energy. It is not intended for commercial operations where speed of drying is important. The original model of this dryer was successfully built and used for years by Curtis Johnson, a retired Forest Service employee.* A newer model designed by Mr. Johnson with greater holding capacity and other improvements is now in operation. This report describes how to build and operate this latest model and the time required to dry some species of wood. The dryer is located in southern Wisconsin at about 43° north latitude.

Johnson, Curtis L. Wind-powered solar-heated lumber dryer. Southern Lumberman, October 1, 1961.

CONSTRUCTING AND OPERATING

A SMALL SOLAR-HEATER LUMBER DRYER

Paul J. Bois

National Wood Drying Specialist

State and Private Forestry

USDA, Forest Service, State & Private Forestry, Cooperative Forestry

One Gifford Pinchot Drive, Madison, WI 53705

Re-Issued 3/1989

Construction[edit | edit source]

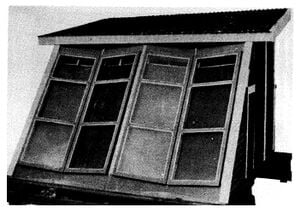

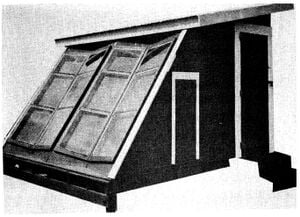

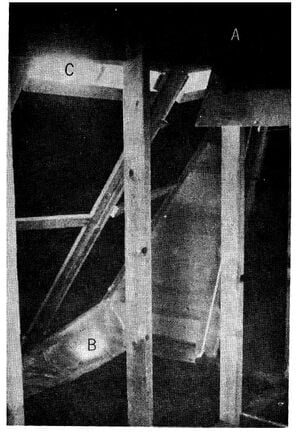

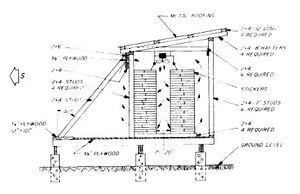

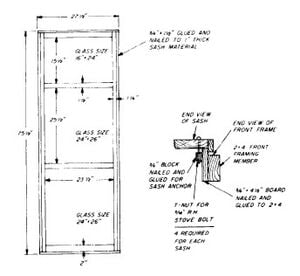

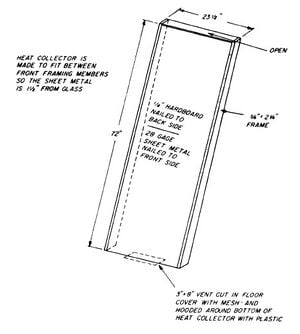

Photos of the lumber dryer are shown in figures 1, 2, and 3. Figures 4, 5, and 6 show the principal dimensions and construction details. Depending on thickness of lumber, the dryer has a capacity of 750 to 850 board feet of 8-foot lumber. The dryer is of all wood construction and insulated. Insulation batts can be tacked to walls and ceiling. The south side of the dryer is enclosed with four storm windows of single-strength glass, giving a glass area of about 47 square feet. The south wall slopes 40 degrees from the vertical and each solar-collecting unit has been rotated slightly in an effort to catch some early morning and late afternoon sunshine. This latter detail may be of questionable benefit and may be considered an optional construction detail. Two vents in the floor are covered with hardware cloth to keep out rodents. These floor vents are each 4 by 10 inches and located under the central “plenum.” The overhead fans (two spaced evenly over the 8-foot dryer load) each deliver 1,200 cubic feet of air per minute downward between the two lumber stacks. Hinged baffles hanging from the fans insure that all air delivered by the fans is directed between the stacks into the “plenum” space so that all available air delivered circulates through the sticker-separated lumber. Plenum space should be 15 to 20 inches wide to insure uniform air distribution through the lumber. The electric fans are activated by a thermostat which is set to turn fans on when the inside temperature reaches 80° F. The window glass units face dull black painted sheet metal and hardboard-backed solar collector units. The top and bottom of each collector unit are open to allow circulation of the heated air. A side door on the east side of the dryer provides loading and unloading access and permits inspection of the lumber. An adjacent smaller door serves as access to the solar-heating area.

The dryer is mounted on treated wood foundation posts set 30 inches in the ground.

Operation[edit | edit source]

The solar dryer captures a part of the sun’s heat and uses it to dry the lumber. By this method, lumber can be reduced to a lower moisture content than by air drying alone and such lumber is suitable for high-quality uses as in furniture. The dryer will bring lumber down to about 8 percent moisture content in time; the time determined by initial moisture content of the lumber, time of year, and species being dried. The manner in which the dryer works is as follows: the sun’s rays pass through the glass and a portion of the available heat is absorbed by the black metal heat collector. The metal in turn heats the air space within. When the fans are in operation, the heated air is circulated through the lumber picking up moisture. Some air is admitted and vented in the process through the floor slots, the necessary amount depending on the moisture content in the dryer. When moisture-laden green lumber is being dried, vents may be left full open; as lumber becomes drier, vents may be gradually closed. The purpose of venting is to keep the relative humidity of the air in the dryer as low as possible while maintaining a high dry-bulb temperature. When the thermostatically controlled fans are not operating, collectors and some drying still takes place as air moves slowly through the the dryer by convection.

It is important that the lumber be stacked properly with uniformly sized 3/4-inch (or thicker) dry stickers separating each course of lumber. Each tier of stickers should be aligned carefully, about 24 inches apart for hardwoods. Further details on good stacking principles are described in the “Air Drying of Lumber, A Guide to Industry Practices,” Agriculture Handbook No. 402, USDA, Forest Service, which is available from the Superintendent of Documents, Government Printing Office, Washington, D.C.

In Wisconsin, dryer temperatures may reach 130° F in the summer and 80° to 90°F in winter. Temperatures will vary in other geographical locations.

Lumber dryer temperatures will also vary as the lumber dries. During the summertime, dryer temperatures with green wood may only reach 10° to 15° F above ambient. Later in summer when the lumber moisture content drops below 20 percent, temperatures in the dryer will climb to 20° to 30° F above ambient. Evaporation is slower and its cooling effect less at the lower moisture contents.

Results[edit | edit source]

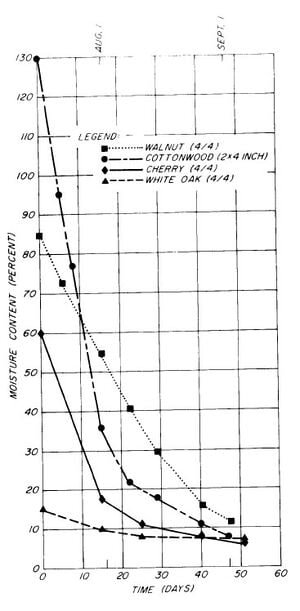

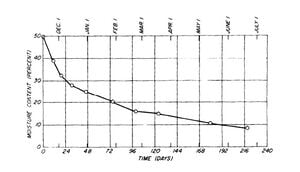

This dryer and earlier models have been operating in southern Wisconsin for over 10 years. Some drying rate curves for species of wood dried are shown in figures 7 and 8. Species dried have been black cherry, black walnut, white oak, and cottonwood. The moisture content of the lumber entering the dryer was determined by cutting small pieces from representative boards and weighing, ovendrying, and reweighing them. As drying progressed, the sample boards from which the pieces called moisture sections had been cut, were placed in representative locations in the dryer and weighed at intervals to determine the drying progress. Sample board techniques are described in “The Dry Kiln Operator’s Manual,” Agric. Handbook No. 188, which is available through the Superintendent of Documents, Washington, D.C. At the end of the drying runs, additional pieces of these same boards were cut and ovendried (215° F) to determine the final moisture content. Readings were also taken with a resistance-type moisture meter to check out additional boards in some charges. As shown in figure 7, the cherry lumber dried from an average of 60 percent moisture content to an average of 6 percent in 52 days. The white oak dried from an average of 15-1/2 percent to an average of about 7-1/2 percent in the same period. This charge was dried during an optimum drying period beginning July 15. Another run was made with freshly sawn black cherry lumber which was placed in the dryer on November 14. As shown in figure 8, the moisture content was reduced from about 50 percent average moisture content to 8 percent in about 218 days. On removal from the dryer, both charges of lumber were bright, clean, and apparently clear of season checks. On another run in the summer of 1976 with cottonwood studs at an initial moisture content of about 130 percent and 4/4 walnut at 85 percent moisture content (fig. 7), started on July 14, moisture contents reached an average of 10 percent and 12 percent, respectively, after 47 days of excellent drying weather. Again, no drying defects were noted.

After experimenting with drying times through the years, Mr. Johnson feels that for summer drying, about 80 days are required to dry the 4/4 green hardwoods mentioned above. He has also determined that this assumes about 70 sun days or a total of about 400 hours of direct sunlight. With full kiln charges and starting with green lumber, only two charges per year can be put through the dryer.

An obvious way of increasing the volume of lumber dried per year is to load the dryer with air-dried stock. Air-dried lumber in the central and eastern United States will generally reach 12 to 15 percent moisture content. Air drying times again depend on species, thickness, latitude, and time of year. Generally species such as oak, pecan, hickory, walnut, and rock elm require from 70 to 200 days, the shorter times for summer drying, the longer periods for material put out in winter. Faster drying species, such as yellow poplar, basswood, cottonwood, hackberry, soft maple, and sycamore, will require 40 to 150 days. An inventory of well air-dried stock ready for the solar dryer could increase the volume output of the solar dryer several times.

It is recommended that green and air-dried stock not be dried together since additional drying of the air-dried stock will be slowed until the green material moisture content approaches that of the air-dried wood.

Drying times for air-dried stock can be estimated by referring to the appropriate drying rate curves. Enter the curve at the proper moisture content and read days remaining to final moisture content.

Materials[edit | edit source]

Suggested List of Materials to Build Solar Dryer

Structure[edit | edit source]

- 9 pieces - Treated posts 5 inches top, 42 inches long

- 2 pieces - 10' 4"x6"

- 2 pieces - 10' 2"x6"

- 8 pieces - 12' 2"x6" floor joists

- 5 pieces - 10' 2"x4"

- 12 pieces - 6' 2"x4"

- 6 pieces - 7' 2"x4"

- 4 pieces - 12' 2"x4"

- 14 pieces - 8' 2"x4"

- 4 sheets - 4'x8' 3/4" plywood underlayment

- 1 piece - 6'x2'6" door

- 300 b.f. - 1"x8" boxcar siding

- 8 pieces - 8' 1"x4" trim

- 6 pieces - 12' 1"x6" trim

- 6 sheets - 25/32" standard sheathing - inside lining

Roof[edit | edit source]

- 5 sheets - 8' Rigid-rib metal roofing

- 1 roll - Foil-faced insulation

Collectors[edit | edit source]

- 25 feet - 24" roll valley tin for heat collector

- 32 l.f. - 1"x6" frames for heat collector

- 24 l.f. - 5/4"x6" sash

- 24 l.f. - 1"x6" sash

- 48 s.f. - Glass

- 2 sheets - 4'x8' 1/8" tempered hardboard

- 1 sheet - 4'x8' 3/8" exterior plywood

See also[edit | edit source]

External links[edit | edit source]

- http://www.motherearthnews.com/library/1982_July_August/A_Homemade_Solar_Lumber_Kiln

- http://www.homepower.com - Don't recall the issue, sometime in 2004 I think.