This project aims to enable the reuse of construction debris for the reconstruction of populated areas, and to promote the development and growth of the culture of re-birth.

In a world where sustainability is at the forefront of our efforts, ingenious solutions for recycling and reusing materials have become vital. Re-birth bricks, also known as reclaimed bricks, offer a brilliant example of how waste can be transformed into valuable resources, providing an eco-friendly alternative to traditional construction materials.

The Transformative Process: From Collection to Creation[edit | edit source]

The journey of a re-birth brick begins with the collection of discarded and broken bricks from various sources. We explore how these reclaimed materials are carefully selected and sorted, ready to undergo a transformative process. From crushing and grinding to mixing with other environmentally friendly elements, we unravel the steps that result in a sustainable and strong re-birth brick.

The Remarkable Environmental Impact of Re-birth Bricks[edit | edit source]

As we delve deeper into the world of re-birth bricks, we uncover their remarkable environmental impact. These bricks not only reduce the burden on landfills but also minimize the need for new brick production, thereby conserving vital natural resources. Through facts and figures, readers will gain a profound understanding of the positive footprint re-birth bricks leave on our planet.

Transforming Waste into Worth: Brick by Brick[edit | edit source]

The evolution of re-birth bricks represents a paradigm shift in the way we perceive waste. From being discarded remnants to invaluable building blocks, re-birth bricks demonstrate the beauty of transformation. Their positive environmental impact and contribution to waste reduction mark a promising path towards a greener and more sustainable future. As we embrace re-birth bricks, let us pave the way for a world where waste finds new worth, brick by brick.

Meanwhile, in the materials laboratory in Ukraine...[edit | edit source]

Planning part[edit | edit source]

While one part of the team is using working recipes to create building blocks, the other part of the team from Ukraine is developing and testing new recipes for building blocks from heavy industry waste. The goal of the team is to create optimal recipes of cheap building blocks for the reconstruction of Ukraine after the end of the war. The main development was a recipe for blocks using red sludge from landfills in the Mykolaiv region (one of the most affected regions of Ukraine).

Using scientific capabilities, we developed a working composition of the material. Our most balanced reciept:

Our mixes consist of two parts: first is "cement part" counted like 100%, second is "fillers", counted like relation to the cement part. Cemente: 55% Red Aluminium sluge; 40% blast-furnace crushed granulated slag; 5% soda ash. Fillers: 275% sand; 150% broken bricks, 170% rubble.

Making part[edit | edit source]

Using the above recipes, we begin to prepare the mix.

Sand must be dried in the sun or with the help of a drying box, bricks must be crushed mechanically.

After 28 days. Compression tests performed on the certified equipment of the Kyiv National University of Civil Engineering and Architecture showed that the prototypes made according to the recipe can withstand more than 30 MPa of pressure.

Re-Birth Brick or Block Processes, turning waste materials in to bricks[edit | edit source]

Re-Birth Brick is a media and digital culture informed bricks prototype for complex post-conflict and politically unstable environments, responsive to refugee, IDP and resource scarce needs. It was created at Pagirinya Refugee Settlement, as response to urgent community-use housing needs.

Progressive processes of how the Re-Birth Bricks has been made.[edit | edit source]

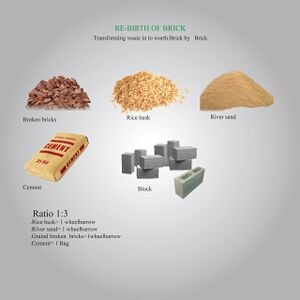

| Broken Bricks or demolished house |

|

|---|---|

| Rich husk | |

| River sand | |

| Cement |

From waste materials to block (e.g materials like broken brick, rich husk and mix together).

Contraction debris based on materials types ( e.g Broken Brick, concrete, wood and hush). Remove any non-recyclable or hazardous materials from the debris like mantel. Clean the debris to remove dust, dirt, and other contaminates. Ensure compliance with safety regulations and provide personal protective equipment (PPE) for workers.

Cushing and grinding waste materials like broken brick to make power forms easily mixing with other materials. Use appropriate machinery to crush and grind the debris into smaller particles to be in power forms or becoming that more like river sand. Ensure that the particle size is consistent and suitable for brick manufacturing.

Tools use for making Re-Birth Brick or Block

- Manual molding block machine

- Hoe

- Shade

- Trowel

- Wheelbarrow

- Rack

- Watery cane