Description[edit | edit source]

▶ Help!

What is your product about?

This project is to replace a broken screwdriver grip. Machinable wax will be used to create a mold to cast resin and make a new grip.

Open Source Hardware[edit | edit source]

▶ Help!

Similar products in OSH search engine. This search engine is customized to look in OSH repositories.

- link1

- link2

- link3

No suitable products are found in OSH, since this project is highly customized.

Category & Type[edit | edit source]

▶ Help!

What is the category of your product?

- Water, Sanitation and Hygiene (WASH)

- Shelter & Settlements

- Disability Inclusion

- Protection & gender-based violence (GBV)

- General

- Environment & Energy

- Nutrition

- Disaster Risk Reduction

- Health

- Child Protection

What is the type of your product?

- Product Prototyping and Development

- Workshops & Training

General - Product prototyping and development

Background & Addressed Need[edit | edit source]

▶ Help!

What does your product solve? Why your product was created? Who will use your product?

The screwdriver is the major part of a bits set. If the screwdriver is not working properly, there will be no benefit from this set, and it will be a waste of essential tool used in general making and maintenance work.

Benefits & Criteria[edit | edit source]

▶ Help!

What are the benefits of your product? What are the design criteria of your product?

Benefits:

- Continue using the bits set

- Save essential tool for maintenance and making

Criteria:

- Fits to screwdriver with same sizing as original part

- Strong, durable, and easy grip

Material, Equipment, & Skills[edit | edit source]

▶ Help!

What is needed to make your product?

Material:

- Machinable wax

- Molding silicone

- Casting resin

Equipment:

- CNC milling machine

- Weighing scale

Skills:

- 3D modeling

- Operation of CNC milling machine

Risk Assessment[edit | edit source]

▶ Help!

Think about the risks related to this product, and level each (NONE, LOW, MEDIUM, HIGH)

- Risks while making product

- Risks while delivery and installation of product

- Risks if product failed

- Risks while using product

- Risks to environment

- Making

- Silicone/resin skin contact and fumes (LOW)

- Injury while using the CNC (LOW)

- Delivery and installation (NONE)

- Failed (NONE)

- Using (NONE)

- Environment

- Silicone/resin wastes (LOW)

Conclusion: risks associated to this products are low, normal workshop precautions are needed.

Maker Instructions[edit | edit source]

▶ Help!

List the steps of making your product. For each step go to Insert > Template and search for "Step"

File Download[edit | edit source]

▶ Help!

Downloadable files (CAD, manuals, …)

Video Instructions[edit | edit source]

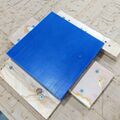

Gallery[edit | edit source]

▶ Help!

Project media. Go to Insert > Gallery

External Resources[edit | edit source]

▶ Help!

Project page in other repository, technical sheets, …

Further Work & Recommendations[edit | edit source]

▶ Help!

What's next? Any recommendations?

- Instead of resin, hard silicone could be used for casting. It will provide a smoother and a better grip.

- It is possible to make the silicone mold using 3D printing.

How to Contribute[edit | edit source]

Contact Details[edit | edit source]

- email: azizwadi79@gmail.com