This article will explore require criteria for the design and fabrication of low-cost oxygen concentrators. If you want to contribute to this article, don't hesitate to do so.

Background[edit | edit source]

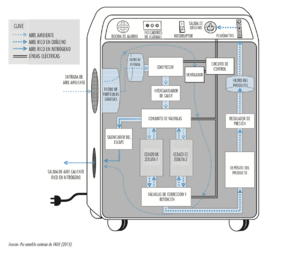

An oxygen concentratorW is a device in which ambient air flows, raising its pressure and making it flow through zeolite, which is an aluminosilicate that has the property that retains nitrogen particles from the air under pressure, allowing oxygen-enriched air to pass into an accumulator container. When the pressure is lowered, it delivers N2-rich air and heat to the enviroment. The O2 enriched air is used for the treatment of patients with hypoxiaW.

This process has to be designed to get breatheable air with a improved concentration of O2. The O2 concentration values for clinical use are among 95% of pure O2.\

Design criteria[edit | edit source]

Cost[edit | edit source]

Specifications[edit | edit source]

- Weight: Less than 30 KG

- Oxygen flow stream: Up to 3 l/min for portable use. Between 5 l/min up to 10 l/min for clinical use. For pediatric use, the system have to provide air flows in order of 0.5 l/min.

- Input power:Between 40 and 130 W for portable use. Between 280 to 600 W for clinical use. Powered by AC current @ 60 Hz.

Air quality[edit | edit source]

The O2 minimum concentration for clinical use is 82% of O2. Concentrator must have an O2 concentration warning system, if the O2 value drop under 82% in the air mix (in according with ISO 80601-2-69:2014 Medical Electrical Equipment – Part 2-69: Particular requirements for basic safety and essential performance of oxygen concentrator equipment)

Operational Description[edit | edit source]

| Component name | Function |

|---|---|

| Case | Storage for internal components |

| Coarse particles filter | Big particles filter to give long-lasting inlet compressor filter life |

| Inlet compressor filter | To filter fine particles preventing damages on compressor and valves |

| Compressor | Rise air pressure on system inlet |

| Fan | Fan cooling system |

| Heat exchanger | Remove heat generated in gas compression system |

| Control circuit | To analize input signals, compression and valves arrangement |

| Valves arrangement | To control flow process through zeolite and escape tubes |

| Zeolite columns | To separate oxygen from the inlet mix air |

| Exhaust muffler | To reduce noise in exhaust air rich in N2 area |

| Accumulator tank | To accumulate O2 rich air to produce a steady and continuous flow |

| Flow meter | To control output flow |

| Output filter | Eliminate particles from the output stream |

| Humidifier | Add moisture to output gas before it will be breathed |

| Oxygen monitor | Make sure concentration of oxygen over 82% in the output gas flow |