Development[edit | edit source]

This tool is still under development. Here is the process till now.

Literature reviewː Open Source Melt Flow Indexer Literature Review - Appropedia

Overall features[edit | edit source]

This tool is employed for the measurement of MFR, which is, succinctly put, the mass of an extrudate under specified conditions. This data is instrumental in differentiating materials based on viscosity and other physical characteristics, thereby aiding in the analysis or application of the materials. A literature review indicates that the measuring apparatus should be equipped with heating, material pressurization, a fixed die, a mechanism for cutting the extrudate, and a system for mass measurement, among other functionalities. Based on the aforementioned specifications, we can proceed with the following design.

Electric design[edit | edit source]

| Name | Model number | Quantity | Source |

| PCB | 1 | JLCPCB | |

| Control board | Teensy board 4.0 | 1 | Teensy.com |

| Motor driver | TMC2130 | 1 | Amazon |

| HX711 | HX711 | 2 | Amazon |

| ADC | MAX31855KASA | 1 | Digikey |

| ? | AMS1117 | 1 | Digikey |

| Force sensor | DYMH-103 | 1 | AliExpress |

| Loadcell | ? | 1 | Amazon |

| SMD Resistor | 10k | 2 | Digikey |

| Capacitors c1 | 100 uF | 1 | Digikey |

| Capacitors c2 | 22 uF | 1 | Digikey |

| Capacitors c3 | 0.01 uF | 1 | Digikey |

| Capacitors c4 | 10 uF | 1 | Digikey |

| FB | ? | 2 | Digikey |

| Thermocouple | ? | 1 | Digikey |

| Connecters | 8 | Digikey | |

| Motor | 1 | Digikey | |

| Servomotor | 1 | Digikey | |

| Power supply | 110v AC to 12V DC | 1 | Amazon |

| Relay module | |||

| Wires | |||

| High temperature-resist wires | 1 | ||

| High temperature-resist connecters | 2 | ||

| Nichrome wire | ? | 1 |

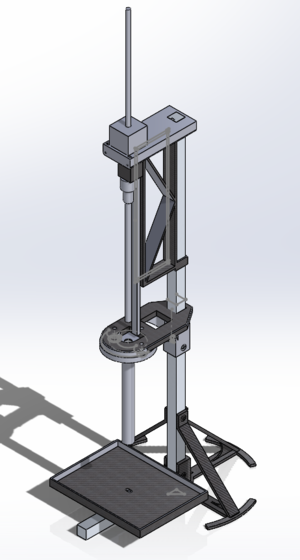

Mechanical design[edit | edit source]

Improvement needed on piston head.

Firmware design[edit | edit source]

The ultimate objective is to achieve full automation. For now, to streamline the design process, the Arduino IDE will be utilized as the user interface for interaction. The automated processes to be implemented are as follows:

- Upon powering on, the initial step involves retracting the piston from the cylinder to facilitate material loading.

- The required pressure, temperature, and duration are input into the IDE.

- After material loading is completed, a command is issued through the IDE to initiate heating. Once the heating phase is completed, the piston automatically descends into the cylinder and continues downward to commence the extrusion of the material.

- Upon reaching the set duration, the cutter is activated followed by the weighing process.