The goal of this project is to create an open source solution to automate the chemical maintenance of a residential pool.

Background and Problem Statement[edit | edit source]

Modern water filtration systems used in residential pool applications require the user to balance and maintain the chemical properties of the water within the system. Unmaintained or unbalanced water causes systems to run inefficiently, or, in extreme cases, the water can damage heating and filtration systems. To maintain and balance the water, the user must determine the water's sanitizer concentration, acidity, and alkalinity, then add the necessary chemicals if correction is needed. In residential systems, this process must be manually completed by the system user.

Vision[edit | edit source]

This project aims to create an open-source system that automates the chemical balance for residential pools. The final product itself will be relatively low maintenance and non-invasive to the existing filtration and heating system. This will be achieved by keeping the project separate from the existing pool system so that it can be implemented in a location that is both accessible and out of the way.

Proposed System [edit | edit source]

To create Open Water, the following user requirements were defined.

- Research and Development:

- Determine by research and testing the best way to obtain information about the state of the water while keeping costs to a minimum

- Determine by testing the best way to deliver chemicals to the water

- Determine if the system should be free-floating in the water, in line with an existing system, or based on land next to the water

- Development and Application:

- Create a housing with a combination of off-the-shelf and 3D printed parts. This chassis will need to:

- House all the dry chemicals without contamination in a wet environment

- Facilitate delivery of all dry chemicals

- House all electronics for determining water quality in a wet environment

- Facilitate the handling of voltage safely in a wet environment

- Create a system to deliver dry chemicals to the water in the appropriate amounts

- Create a low-cost system that determines the following chemical properties of a given sample of water:

- Ph level

- Alkalinity level

- Free chlorine level

- Bromine level

- Hardness (calcium) level

- Create a housing with a combination of off-the-shelf and 3D printed parts. This chassis will need to:

From these user requirements, the following specific system requirements were determined:

- The housing used must meet IP67 standards

- All dry chemicals must be stored without contamination in a wet environment using airtight containers

- Implementation of a GFCI system is necessary for electrical safety

- All electronics should be run on low voltage and low direct current.

- The status of the water will be determined using a 6 channel 16 bit color sensor

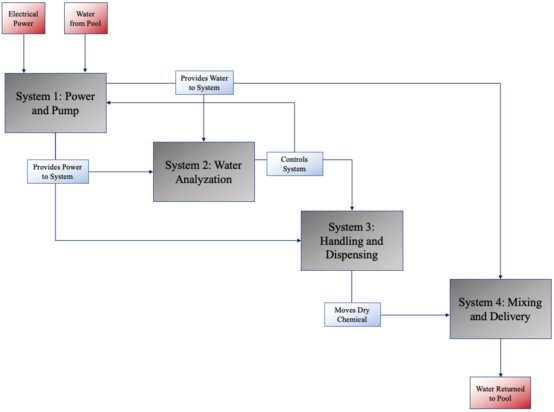

The following subsystems will be created to achieve the goals of the project.

- Power and Pump: Handles the conversion and dispersion of electrical power and pool water to the other subsystems as needed

- Water Analyzation: Accepts an off-the-shelf pool test strip and utilizes a 6 channel, 16-bit color sensor to determine the state of the water. Using a lookup table, the device will then determine the corrective action necessary for the water and respond accordingly.

- Handling and Dispensing: Accurately dispenses dry powder into the mixing chamber as needed. Open Water will have the capability to deliver 4 different types of dry chemicals to the pool.

- Mixing and Delivery: Dilutes the dry powder chemical with water before returning it to the pool. Undissolved chemical sitting on the bottom of the pool can cause damage to the liner. The mixing system will eliminate this possibility preventing this type of damage.

This device will be made using off-the-shelf items that can be purchased online or at a hardware store. Any custom-designed parts necessary for the system's function will be 3D printed. The total cost to build this project will be under $250

Research and Market[edit | edit source]

Current commercial solutions that automate this balancing process include the Pentair IntelliChem and the Hayward HCC 2000. Costing upwards of $3,100 and $2,200 respectively, these systems are somewhat limited and expensive. Both systems only balance pH and sanitizer levels, leaving the user to monitor and adjust the water's calcium and alkalinity levels manually. Current DIY solutions are similarly limited. Raspipool uses an inline system of probes to determine water quality and peristaltic pumps to inject liquid chemicals into the water. It is estimated that this system can be built for $350 to $500. Similar to commercial systems, it can only measure two properties of the water.

The probe system used by these available systems is expensive and prone to failure. Of the four significant water properties, pH, sanitizer, calcium, and alkalinity, only pH can be directly measured using a probe sensor. Oxidation reduction potential (ORP) is also usually measured with a second probe. Combining this data with the pH of the water, the system can determine the sanitizer level.

Because of the inadequacies of this system, pool test strips paired with a color sensor were chosen to determine the water quality in Open Water. Pool test strips are standardized, precise, accurate, inexpensive, and widely available. Each test strip contains several pads that, when immersed in water, change color based on the water quality. In a residential pool, the user compares the test strip to a chart to determine the properties of the water. In the Open Water system, the test strip is read using a 6-channel 16-bit color sensor. Then, using a lookup table, the microcontroller onboard the device can determine the necessary amounts of each chemical to add. This system will be fully developed in upcoming semesters.

Filament Test[edit | edit source]

For Open Water to be successful, custom parts will be required; to fulfill its goal of being low maintenance, each part must withstand the wet, chemical-rich environment it will be in. An article by Dr. Joshua Pearce et al. titled Chemical compatibility of fused filament fabrication-based 3-D printed components with solutions commonly used in semiconductor wet processing explores the application and durability of 11 different filaments in a lab setting.[1] The chemicals used in this study were, in many cases, much harsher than the expected environment of Open Water. Nevertheless, the article gives a good indication of the best filaments for use in Open Water. The results of this study point to PETG and NGEN as strong candidates for harsh chemical immersion. The best chemical determined was PP. However, this material is hard to print with and will likely not be used for this project.

To better understand the properties of filaments within the context of Open Water, an 8-week filament test was initiated. To begin, 500 ml of tap water was balanced for ideal pH and alkalinity using commercially available pool chemicals. For this process, the water was treated with enough chlorine to achieve 20 ppm. Then, 100 ml of water was transferred to 5 separate containers, and 2.7 grams of filament was added to each one. The 5 filaments tested were PLA, PP, PETG, CPE, and ABS. In 8 weeks, the material properties of each of the 5 filaments will be evaluated. Combining these results with the recommendations from Dr. Pierce's article will determine the filament used for the parts in Open Water.

Major Component: Powdered chemical delivery system[edit | edit source]

A critical function of Open Water is to accurately deliver each of the four dry chemicals to the mixing chamber. To do this, the pictured device was created. It consists of clear vinyl tubing clamped in place by a housing. Within the tube is an auger rotated using a 28byj 48 stepper motor.

- The first physical prototype of the dry mover assembly created for Open Water.

-

-

Proof Testing[edit | edit source]

To determine the precision and accuracy, the device was filled with table salt as a stand-in for powdered chemicals. The shaft was then rotated 10 full revolutions, and the mass of the dispensed salt was observed. This process was repeated 10 times with the following results:

| Run # | Observed

Mass |

|---|---|

| 1 | 0.80 |

| 2 | 0.85 |

| 3 | 0.81 |

| 4 | 0.83 |

| 5 | 0.87 |

| 6 | 0.85 |

| 7 | 0.85 |

| 8 | 0.86 |

| 9 | 0.84 |

| 10 | 0. |

For these 10 runs, the average mass dispensed was.85 grams with a standard deviation of +-.02 grams. This equates to a relative standard deviation of 2.79%.

Application[edit | edit source]

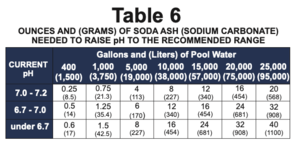

Having a reliable way to dispense chemicals gives Open Water the ability to take corrective action. For example, according to Haywards Pool Chemistry Guide, a 400-gallon spa with a pH level between 6.7 and 7.0 requires 14 grams of sodium carbonate to raise the pH to the recommended range of 7.2 to 7.8.[2] In this scenario, Open Water will dispense these 14 grams of sodium carbonate by rotating the auger 16.5 revolutions.

Lookup tables like those used here are commonly provided by pool equipment and chemical manufacturers like Hayward, Clorox, and BioGuard. This information will be programmed into Open Water so that it can safely balance the water once it has obtained a reading.

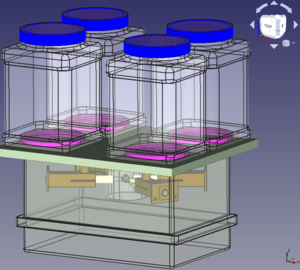

Current Design[edit | edit source]

The current design of the system is pictured below. It includes 4 containers that feed 4 powdered chemical delivery systems. The powdered chemical is fed into the central mixing chamber and combined with water before it is returned to the pool.

Once the project is fully developed, the subsystems will interact as shown below.

Bill of Materials[edit | edit source]

To build the Open Water system, the following materials are needed. An estimated cost has been included for each part.

| Name | Link | Estimated Cost | Actual Cost | qty | status |

| Storage containers | ~ | $11.88 | $2.97 | 4 | local pickup |

| Hard plastic tubing | ~ | $5.00 | 1 | local pickup | |

| Flexible tubing to run into pool and to pump | ~ | $5.00 | 1 | local pickup | |

| Flexible fitting | ~ | $2.00 | 1 | local pickup | |

| Drill bit for auger | ~ | $8.00 | 1 | local pickup | |

| Rubber seals for inside and outside | ~ | $1.00 | 1 | local pickup | |

| Silicon sealant | ~ | $5.00 | 1 | local pickup | |

| Water pump | Amazon | $29.99 | $29.99 | 1 | on order |

| Adafruit Color Sensor | Adafruit | $19.95 | $19.95 | 1 | on order |

| filament | 1 | need further research | |||

| stepper motor | Amazon | $13.99 | $13.99 | 1 | hardware for final product |

| Arduino mega | Amazon | $20.99 | $20.99 | 1 | hardware for final product |

| enclosure | Amazon | $35.99 | $35.99 | 1 | on order |

| relay module | Amazon | $6.79 | $6.79 | 1 | on order |

| GFCI outlet | ~ | $20.00 | 1 | local pickup | |

| mains electrical mounting box, wire nuts | ~ | $5.00 | 1 | local pickup | |

| waterproof cable connector | ~ | $5.00 | 1 | local pickup | |

| pool test strips | Amazon | $22.49 | $22.49 | 1 | on order |

| Estimated Cost | $218.07 | ||||

| Running Actual Cost | $162.07 | ||||

| Remaining budget | $87.93 | ||||

Print List[edit | edit source]

The following parts need to be printed to build the Open Water system. All parts and the full assembly file are available on this project's GitHub. All files are made using FreeCAD and can be easily edited.

| Identified Part | System | Status | Printed | Designer |

|---|---|---|---|---|

| Bit Adapter | 3 | Version 1 | Yes - Prototype Plastic | Noah Jaeger |

| Container | 3 | Part | n/a | Noah Jaeger |

| Container Top | 3 | Part | n/a | Noah Jaeger |

| Delivery Funnels | 3 | Version 3 | No | Noah Jaeger |

| Hardline | 3 | Variable Part | n/a | Noah Jaeger |

| Housing | Structural | Variable Part | n/a | Noah Jaeger |

| Joiner Connector | 3 | Version 3 | Yes - Prototype Plastic | Noah Jaeger |

| Joiner Body | 3 | Version 3 | Yes - Prototype Plastic | Noah Jaeger |

| Mixer | 4 | Version 1 | No | Noah Jaeger |

| Pump Mount | 1 | Version 1 | No | Noah Jaeger |

| Support Board | Structural | Variable Part | n/a | Noah Jaeger |

| Stepper Motor | 3 | Part | n/a | Anthovdc Via Thingiverse |

| Auger | 3 | Part | n/a | McMaster-Carr |

Current Status[edit | edit source]

This project is ongoing and is expected to be completed by May of 2023; the estimated budget will certainly fluctuate, and new components will be added to the print list before the project is concluded. At this point, subsystems 1 and 3 have been designed. Initial prototypes and tests have been completed for system 3. Subsystem 4 is in development. This project is on track to finish subsystems 1,3, and 4 and have subsystem 2 well developed by December 2022.

References[edit | edit source]

- ↑ Pearce, J. M., Kauppinen, C., Liu, Z., Asikainen, S. M., Spoljaric, S., Seppälä, J. V., & Savin, H. (2018). Chemical compatibility of fused filament fabrication-based 3-D printed components with solutions commonly used in semiconductor wet processing. Additive Manufacturing, 23, 99–107. https://doi.org/10.1016/j.addma.2018.07.015

- ↑ 2.0 2.1 Chemistry Quick Start Guide. Hayward Pool Assets. (2014). Retrieved June 25, 2022, from https://hayward-pool-assets.com/assets/documents/pools/pdf/manuals/Chemistry-Quick-Start-Guide.pdf?fromCDN=true