The Plasma Discharge System consists of a voltage regulator, a plasma generator unit, and a reactor. It is typically employed for conducting arc discharge, dielectric barrier discharge, and glow discharge tests in various atmospheres such as air, oxygen, nitrogen, and other inert gases.

The objective of this project is to build a power supply for the experimental plasma discharge setup. The application-specific solar power supply includes an MPPT (Maximum Power Point Tracker) and an inverter specifically designed for this application. These components will be integrated into a single compact, cost-effective, and open-source package.

Description plasma discharge experimental setup[edit | edit source]

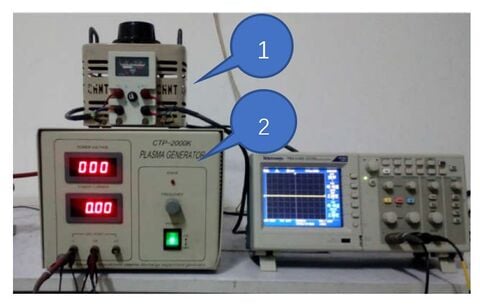

Plasma discharge system setup

Product composition

1. CTP 2000K Plasma power supply.

- Product name: Low temperature plasma experimental power supply

- Model: CTP 2000K

- Output voltage(kV): 0-30

- Frequency(kHz): 5-20

- Power(W): 0-500

2. TDGC2-1 Contact Voltage Regulator (Resistive).

- Rated input voltage: 220v

- Rated capacity: 1kVA

- Frequency: 50Hz

- Output voltage range: (0-250) V

- Rated output current: 4A

- Weight: 6.5kg

3. DBD Reactor.

Proposed power supply unit[edit | edit source]

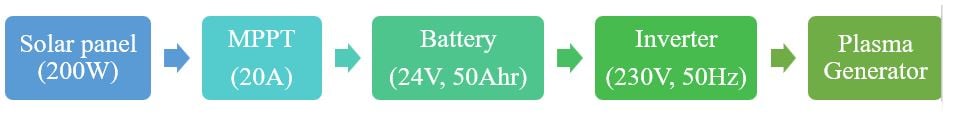

| S.L. | Type | Specification |

|---|---|---|

| 1 | PV | 200W |

| 2 | MPPT | 20A |

| 3 | Inverter | 230V, 50Hz (500W) |

| 4 | Battery | 24V, 50Ahr |

Literature review on "Open source solar power supply unit for plasma generator"[edit | edit source]

Applications of plasma discharge

1. Hydrogen Production from Hydrocarbons with Use of Plasma Discharges Under High Pressure Condition[1]

Yasushi Nishida et al. are developing a novel H2 production system utilizing plasma discharges, specifically designed for high-pressure conditions exceeding 1.5 atm. The system, intended for installation in moving vehicles, currently explores methane and propane, achieving an approximate 60% H2 yield in comparison to residual CH4 with 138 Whr input energy.

2. Large capacity hydrogen production by microwave discharge plasma in liquid fuels ethanol[2]

Bing Sun et al. investigate large-capacity hydrogen production through microwave discharge plasma in liquid ethanol. Their study with a direct standing wave coupling reactor explores optimized conditions, achieving a hydrogen flow rate of 72.48 g/h, a concentration of 58.1%, and an energy yield of 48.32 g/kWh.

3. Hydrogen generation by glow discharge plasma electrolysis of methanol solutions[3]

Zong Cheng Yan et al. delve into hydrogen generation through glow discharge plasma electrolysis of methanol solutions. The study highlights the dominance of H2 and HCHO in methanol decomposition, with higher hydrogen yield and significantly lower energy consumption in cathodic GDPE compared to anodic GDPE, particularly at 700 V discharge voltage.

4. Application of a non-thermal surface plasma discharge in wet condition for gas exhaust treatment: NOx removal[4]

J. Jolibois et al. investigate the application of a non-thermal surface plasma discharge for NOx removal in wet conditions, studying its efficiency in gas exhaust treatment under low flow rates (1 L/min) and 100 ppm of NO.

5. Characterization of DBD plasma source for biomedical applications[5]

M. Kuchenbecker et al. characterize a Dielectric Barrier Discharge (DBD) plasma source for biomedical applications. This DBD plasma source, featuring a ceramic-covered electrode, operates under steady-state conditions without additional gas flow and is studied for potential treatment of biological objects.

6. High-Frequency Underwater Plasma Discharge Application in Antibacterial Activity[6]

M.W. Ahmed et al. explore the antibacterial activity of high-frequency underwater plasma discharge. Using a neon transformer, they achieve effective inactivation of Gram-negative Escherichia coli in aqueous systems, with no remarkable E. coli rebirth even after 72 hours of plasma treatment.

Solar powered Plasma generators

There are very few literature's available that describes the design of a complete solar-powered plasma generation system. This section will only cover those literature:

7. Compact Microsecond Pulsed Power Generator Driven by Solar Energy for Dielectric Barrier Discharge Applications[7]

Zhi Fang et al. designed a compact solar-powered plasma generator system for driving a DBD reactor. The pulsed power supply is capable of delivering high voltage pulses up to 20 kV, with a pulse repetitive frequency ranging from 1 Hz to 2 kHz and a maximum output power of 150 W.

- The pulse power generator is designed to have a maximum output power of 150 W, with an additional 100 W margin to account for insufficient sunlight and power loss in the microsecond-pulse power generator.

- In cases where the output power of the solar panel under weak light conditions cannot meet the DBD application requirements, the solar panel can be replaced with commercial batteries, providing an output voltage in the range of 9-36 V.

- The input voltage range is 10-60 V, matching both the output voltage range of the solar panel and the battery. The output voltage for the PV converter ranges from 3 V to 90 V, and the transformer winding turn ratio is 1:50.

- However, the system employs a PWM-type DC-DC converter that does not optimize PV power, and the switching circuit for high-frequency operation lacks a ZVS mechanism, resulting in high power losses and poor efficiency.

8. Design of Adjustable High Voltage Pulse Power Supply Driven by Photovoltaic Cells for Cold Plasma generation[8]

Mengqi Li et al. designed a solar-powered plasma generator that employs a multi-stage boost converter to adequately increase the voltage. They utilize a Marx generator to adjust the frequency (ranging from 500Hz to 5kHz) and, subsequently, a transformer to elevate the voltage to up to 10kV for plasma generation.

- The first-stage boost converter employs the MPPT algorithm to charge the battery.

- A six-stage Marx generator is employed, along with a transformer featuring a 1:18 turns ratio and adopting a double-wire parallel winding method.

- They conducted tests on their plasma generator using three types of discharges: N-APPJ, DBD, and pin plate.

9. A solar powered handheld plasma source for microbial decontamination applications.[9]

Y Ni, M J Lynch et al. Mengqi Li et al. designed a handheld plasma source for microbial decontamination.

- A remarkably lightweight device, weighing only 750g, powered by a solar-charged battery.

- The reduction in the number of microorganisms ranged from 2 to 8 log, strongly influenced by the conditions of plasma generation.

- In the SMPS unit, a boost converter is employed to elevate the nominal 7.4V from the LiPo battery to 30V. Subsequently, a MOSFET half-bridge chops the 30V DC signal into a high-frequency square wave, suitable for driving a miniature high-voltage transformer. The transformer's output is directly connected to the SBD electrodes.

- With a fully charged battery, it was observed that a plasma dissipating 10W could be sustained continuously for approximately 1 hour, indicating an efficiency on the order of 85%, which is typical for switched-mode power sources of this nature.

- While suitable for low-power plasma, scaling up poses a challenge for this type of device.

10. Solar powered decentralized water systems: A cleaner solution of the industrial wastewater treatment and clean drinking water supply challenges[10]

Ainy Hafeez, Zufishan Shamair et al. designed the decentralized waste water treatment using solar power plasma system.

- AC power is supplied to the reactor to generate plasma between the live and ground electrodes at atmospheric pressure (Liu et al., 2017a). The breakdown of air occurs at 3.8 kV with a current frequency of 37 kHz.

- The potential solution for achieving a clean drinking water supply could lie in a decentralized drinking water system that incorporates an advanced oxidation reactor powered by solar energy. In their setup, a plasma generator, powered by a solar inverter system, was employed.

- Although they provided a schematic of the process, experimental implementation was not carried out.

Solar power system for individual purposes

11. Portable autonomous solar power plant for individual use[11]

Javoxir Toshov et. al. designed a portable solar power plant based on solar battery.

- The solar panel generates 20 watts of power, and the inverter can handle up to 300 watts with an output voltage of 220V and a frequency of 50Hz. The battery has a capacity of 14Ahr which can power a TV and room lighting for up to 4 hours, or just the room lighting for 20 hours.

- Maximum power tracking algorithms hasn't been implemented and no proper battery charging methodology has been followed.

12. Off-Grid Hybrid Online Solar Power Conditioning Unit for Domestic Purposes[12]

Mohit Chaudhari et. al. designed a UPS that supplies power to the grid from battery and uses MPPT charge controller to utilize solar power.

- Buck converter with MPPT implementation has been used to charge 48V battery bank.

- DSPic controller is used which is a hybrid combination of DSP processor and micro-controller.

- IGBT based inverter is used. And a hybrid IGBT driver is used which isolates the PWM gate signal and amplifies it. And an opto coupler is used to provide electrical isolation between driver and controller.

- Efficiency of the system is very high which is above to 85 percent at full load.

13. Solar Power Inverters[13]

Regine Mallwitz et. al. from SMA Solar Technology AG, which is global acting market leader for solar inverters with more than 4 GW worldwide installed power, classified the grid connected inverters in three generation and discussed their packaging and configurations in this paper.

- They found the booming of inverter market is mostly for grid connected inverters where on the other side number of solar inverters for island installations or individual use is by far less.

- The efficiency of first generation inverters were around 90% where the 2nd generation inverter had around 96-98% and the latest 3rd generation inverter has 99% of efficiency due to development of SiC based semiconductor devices.

- Due to the allowed maximum feed-in power for single phase grids of 5kW, most of all inverters are established in this power range.

14. Research and Design of Inverter Applied in Solar PV Systems Connected to Distribution Grid[14]

Nguyen Duc Minh et. simulated and designed experimental prototype of 5kW grid connected PV smart inverter.

- They incorporated P&O MPPT algorithm in boost converter to track maximum power before the DC to AC conversion.

- They have utilized dq frame to control currents of the three phase smart inverter which regulates the reactive power to zero at the point of common connection (PCC).

- They found the efficiency of the inverter after three different load cased around 89.15% and total harmonic distortion thd= 4.14% (<5%).

15. Design and Validation of a Modular Control Platform for a Voltage Source Inverter[15]

Hernan Lezcano et. al. presented a modular design for signal acquisition and control hardware design for IGBT based commercial VSI converter for isolated and grid connected system.

- The system is capable of supplying 3 phase power to about 10kW load.

- They did three types of test on the system: Open loop, closed loop test and total harmonic distortion analysis. Where they found THD level of 5.3%.

- All their design files and codes are open source - NU General Public Licensed(GNU GPL v3).

- ↑ Y. Nishida, C.-Z. Cheng, K. Iwasaki, Hydrogen Production From Hydrocarbons With Use of Plasma Discharges Under High Pressure Condition, IEEE Transactions on Plasma Science. 42 (2014) 3674–3680. https://doi.org/10.1109/TPS.2014.2337351.

- ↑ B. Sun, X. Zhao, Y. Xin, X. Zhu, Large capacity hydrogen production by microwave discharge plasma in liquid fuels ethanol, International Journal of Hydrogen Energy. 42 (2017) 24047–24054. https://doi.org/10.1016/j.ijhydene.2017.08.052.

- ↑ Z.C. Yan, C. Li, W.H. Lin, Hydrogen generation by glow discharge plasma electrolysis of methanol solutions, International Journal of Hydrogen Energy. 34 (2009) 48–55. https://doi.org/10.1016/j.ijhydene.2008.09.099.

- ↑ J. Jolibois, K. Takashima, A. Mizuno, Application of a non-thermal surface plasma discharge in wet condition for gas exhaust treatment: NOx removal, Journal of Electrostatics. 70 (2012) 300–308. https://doi.org/10.1016/j.elstat.2012.03.011.

- ↑ M. Kuchenbecker, N. Bibinov, A. Kaemlimg, D. Wandke, P. Awakowicz, W. Viöl, Characterization of DBD plasma source for biomedical applications, J. Phys. D: Appl. Phys. 42 (2009) 045212. https://doi.org/10.1088/0022-3727/42/4/045212.

- ↑ M.W. Ahmed, S. Choi, K. Lyakhov, U. Shaislamov, R.K. Mongre, D.K. Jeong, R. Suresh, H.J. Lee, High-frequency underwater plasma discharge application in antibacterial activity, Plasma Phys. Rep. 43 (2017) 381–392. https://doi.org/10.1134/S1063780X17030011.

- ↑ Z. Fang, Y. Shi, F. Liu, and R. Zhou, “Compact microsecond pulsed power generator driven by solar energy for dielectric barrier discharge applications,” IEEE Trans. Dielectr. Electr. Insul., vol. 26, no. 2, pp. 390–396, Apr. 2019, doi: 10.1109/TDEI.2018.007725.

- ↑ M. Li, K. Luo, and Z. Xiong, “Design of Adjustable High Voltage Pulse Power Supply Driven by Photovoltaic Cells for Cold Plasma Generation,” in 2021 IEEE 4th International Electrical and Energy Conference (CIEEC), May 2021, pp. 1–6. doi: 10.1109/CIEEC50170.2021.9510416.

- ↑ Y. Ni, M.J. Lynch, M. Modic, R.D. Whalley, J.L. Walsh, A solar powered handheld plasma source for microbial decontamination applications, J. Phys. D: Appl. Phys. 49 (2016) 355203. https://doi.org/10.1088/0022-3727/49/35/355203.

- ↑ A. Hafeez, Z. Shamair, N. Shezad, F. Javed, T. Fazal, S. ur Rehman, A.A. Bazmi, F. Rehman, Solar powered decentralized water systems: A cleaner solution of the industrial wastewater treatment and clean drinking water supply challenges, Journal of Cleaner Production. 289 (2021) 125717. https://doi.org/10.1016/j.jclepro.2020.125717.

- ↑ J. Toshov and E. Saitov, “Portable autonomous solar power plant for individual use,” E3S Web Conf., vol. 139, p. 01087, 2019, doi: 10.1051/e3sconf/201913901087.

- ↑ M. Chaudhari, K. Babu, S. W. Khubalkar, and S. Talokar, “Off-Grid Hybrid Online Solar Power Conditioning Unit for Domestic Purposes,” in 2019 International Conference on Computing, Power and Communication Technologies (GUCON), Sep. 2019, pp. 121–126.

- ↑ R. Mallwitz and B. Engel, “Solar power inverters,” in 2010 6th International Conference on Integrated Power Electronics Systems, Mar. 2010, pp. 1–7.

- ↑ Nguyen Duc Minh, Trinh Trong Chuong, Bui Van Huy, Quach Duc Cuong, and Bui Dinh Thanh, “Research and Design of Inverter Applied in Solar PV Systems Connected to Distribution Grid,” J Electr. Eng., vol. 7, no. 1, Feb. 2019, doi: 10.17265/2328-2223/2019.01.006.

- ↑ H. Lezcano, J. Rodas, J. Pacher, M. Ayala, and C. Romero, “Design and Validation of a Modular Control Platform for a Voltage Source Inverter,” HardwareX, vol. 13, p. e00390, Mar. 2023, doi: 10.1016/j.ohx.2022.e00390.