The liquid fluoride thorium reactor (or LFTR; pr. "lifter") is a thermal breeder reactorW which uses thoriumW in a fluoride-based molten salt. It operates at high temperatures and atmospheric pressure, and is hoped to provide a safe form of commercial-scale nuclear energy.

It is considered inherently safe due to the nature of the process and the materials, unlike conventional nuclear power.

The basic safety characteristics and major reduction of nuclear waste are very attractive. However, current research and development programs mention targets of around 20 years in the future. Thus while it remains an interesting research prospect, it cannot be relied upon as a future energy source or means of reducing greenhouse gases in the near term. Experience with technologies predicted to be ready so far in the future (e.g. nuclear fusion which has stayed at a predicted 20 years in the future for many decades) warns us not to rely on such predictions.

History[edit | edit source]

The LFTR is an advanced reactor design based on prior designs of Molten Salt Reactors (MSR) developed in the mid 20th century. Molten salt reactors were first investigated in the Nuclear Energy for Propulsion of Aircraft (NEPA) and subsequent Aircraft Nuclear PropulsionW (ANP) projects which officially launched in 1946 and lasted until 1961. These projects aimed to create a nuclear powered bomber that could remain airborne for substantially longer periods of time than conventional military aircraft. The project was overseen by the Atomic Energy Commission (AEC) and the design and implementation was done by Oak Ridge National Laboratory (ORNL).

Design considerations for a nuclear powered aircraft were very particular, and the MSR had several technical advantages over conventional light water reactorsW (LWR). Typical US Air Force bombers could not carry a conventional reactor aboard because they were too large to fit into an engine bay and too heavy to allow for lift. MSRs can be designed to be much more compact and lightweight in order to build them into a jet engine. MSRs also had the advantage running on a liquid fuel, which is more stable than a solid fuel and has a negative temperature coefficient of reactivity, which was important form a stability standpoint. A negative temperature coefficient of reactivity means that a temperature increase lowers the rate of reactivity in the core: were heat from fission and decay in the core to increase past optimal conditions, the fuel itself would expand, lowering the rate of internal reactions and bringing the temperature back down to a stable point. Molten salt also has a low vapor pressure, allowing the reactor to operate at high temperatures without fear of pressurization, which added another layer of safety and reliability to the design.

ORNLs eventual reactor design would be known as the Aircraft Reactor Experiment (ARE). The 2.5 MW MSR used uranium tetrafluoride in molten salt for the fuel, beryllium oxide moderators, and liquid sodium for a secondary coolant. The reactor was built to fit a direct air cycle engine, where the reactor would heat air from a compressor and send it out through a turbine, creating thrust.

In 1954 the ARE operated for a thousand-hour cycle, but the project was cancelled soon after and an operational aircraft was never built. Although the project was considered a failure by many, it did provide enough basis for more research and development into MSRs.

In 1960 The AEC commissioned the Molten-Salt Reactor ExperimentW (MSRE) to be conducted at ORNL. The goal of this project was to see if molten salt reactors could prove itself to be a safer alternative to LWRs. By 1964 the reactor had been built, going critical in 1965 and operated until 1969. The reactor put out 7.4 MW of thermal power using a combination of uranium tetrafluoride fuels; both U-235 and U-233 (which would later become the fissile fuel used by the LFTR and other thorium fuel-cycle reactors). The reactor used a slightly different combination of fluoride salts for the fuel, and used a FLiBe (fluoride, lithium, beryllium) salt for the coolant. additionally, the MSRE used pyrolyticW graphite as a moderator and was constructed out of Hastelloy-NW (a highly corrosion-resistant alloy).

The reactor ran smoothly for 1.5 years of full power operation, and in that time provided ample data and statistics to show that MRSs were viable. The ORNL team had shown that they could overcome many of the issues that the ARE had, and that MSRs could become the most reliable and safe reactors on the market if they were developed commercially. Despite its progress, the MSRE was shut down in December 1969 and eventually decommissioned.

Recently, MSR designs like the LFTR have been investigated by Japan, China, the UK, and private entities in the US.

Two fluid and one fluid reactors[edit | edit source]

Two concepts were investigated at Oak Ridge - "two fluid" and "single fluid" designs.

Two Fluid Reactor[edit | edit source]

The "two fluid" reactor has a high-neutron-density core that burns uranium-233 from the thorium fuel cycle. A separate blanket of thorium salt absorbs the neutrons and eventually is transmuted to 233U fuel.[1]The design weakness of the two-fluid design was its complex plumbing. It used brittle graphite pipes to hold the fuel salt, separating it from the breeding salt. However, graphite expands under intense neutron bombardment, causing leaks. More recently, copper-reinforced graphite fiber cloth has been identified as theoretically suitable, but no physical tests have been done. This type of reactor was never constructed.[2]

Single Fluid Reactor[edit | edit source]

The "one fluid" reactor was mechanically much simpler. It was prototyped as the Molten-Salt Reactor Experiment, mentioned above. It was a large tank with graphite moderator rods immersed in molten salt. By carefully sculpting the moderator rods, and modifying the fuel reprocessing chemistry, thorium and uranium salts could coexist in a simpler, cheaper but efficient "single fluid" reactor.

However, the reprocessing chemistry was much more complex. No simple, proven methods could separate the the nuclear ashes (fission products) from the fuels.

Another issue was that the pipes became brittle due to by radiation and exposure to tellurium, a fission-product. This can be overcome, according to research, by adding a trace amount of titanium or niobium to alloy.[3]

Advantages[edit | edit source]

Thorium-fueled molten salt reactor offers many potential advantages:[4]

Safety[edit | edit source]

- inherently safe design: reactor features passive nuclear safety, strong negative temperature coefficient of reactivity and atmospheric operating pressure. (since the core is not pressurised, it cannot explode)

- Most MSFRs include a freeze plug at the bottom that has to be actively cooled, usually by a small electric fan. If the cooling fails, say because of a power failure, the fan stops, the fuel in the plug melts, and the fuel drains to a subcritical storage facility, totally stopping the reactor.

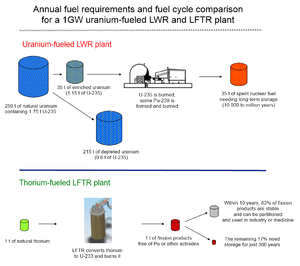

- Reduced radiotoxicity of reactor wastes. The LFTR uses the Thorium fuel cycle, which transmutes Thorium to U233. U233 has two chances to fission as a thermal reactor bombards it with neutrons (as U233 and U235). The fraction of fuel reaching U236, and transmuting into a transuranic element is less than 0.1%.[5] The radiotoxicity of the remaining fission products is dominated by Cesium 137 and Strontium 90. The longer half-life is Cesium, at 30.17 years. So, after 300 years, decay reduces the radioactivity of the cesium to only 0.1%. A related advantage is that the U233 is relatively pure, without other isotopes that are not fuels. In contrast, Uranium fuels are between 97% and 80% U238, which reactors normally transmute to Pu239, a toxic transuranic element. When the two features are combined, the effect of a Thorium fuel cycle is to reduce the production of transuranic wastes by more than a thousand-fold compared to a conventional once-through light-water reactor.

- continuous removal of transmutation products insures that only small amount of them is present in an active reactor at any given time, compared to conventional LWR reactors.

- fluoride combines ionically with almost any transmutation product. This is an MSFR's first level of containment. It is especially good at containing biologically active "salt loving" wastes such as Cesium 137.

- given an accident beyond the design basis for the multiple levels of containment, dispersion into a biome is difficult. The salts do not burn, explode or degrade in air or water, and the fluoride salts of the radioactive actinides and fission products are generally not soluble in water or air.

- the reactor is easy to control at all times. Xenon-135, an important neutron absorber — that makes reactors difficult to control is removed at a predictable, containable place, where the fuel is coolest and most dispersed, namely the pump bowl. In solid-fuel reactors, it remains in the fuel and interferes with control.

- the reactor operates at or above 650C, well above the 250C Wigner annealing temperature of graphite. This means that Wigner energy cannot accumulate in the graphite moderator. The continual annealing bleeds it off. So, a sudden release of Wigner energy is not possible, and as such, a Windscale-style graphite-incited fire cannot be caused by the graphite's nonexistent Wigner energy.

- proliferation resistance: LFTR produces only at most 9% more fuel than it burns in each year. Building bombs quickly will take power plants out of operation. Also, an easy variation of the thorium fuel cycle would contaminate the thorium-232 breeding material with chemically inseparable thorium-230. The thorium-230 breeds into uranium-232, which has a powerful gamma-ray emitter in its decay chain (thallium-208) that makes the reactor fuel 233U/232U impractical in a bomb ,[6] because it complicates bomb manufacture, harms electronics and reveals the bomb location.

Economy and efficiency[edit | edit source]

- since all natural thorium can be used as a fuel, and the fuel is in the form of a molten salt instead of solid fuel rods, expensive fuel enrichment and solid fuel rods validation procedure and fabricating process is not needed, greatly decreasing LFTR fuel cost

- LFTR uses an abundant world supply of thorium to breed uranium-233 fuel. The Earth's crust contains about three times as much thorium as 238U, or 400 times as much as 235U, which makes it about as abundant as lead. Thorium, a byproduct of rare-earth mining normally discarded as waste currently costs US$ 30/kg, while the price of uranium has risen above $100/kg, not including the cost of enrichment, and fuel element fabrication. When used in a LFTR, there is enough economically recoverable thorium on Earth to satisfy the global energy needs for hundreds of thousands of years.[7] In addition to thorium, LFTR can also use nuclear waste from traditional nuclear power plants as a fuel

- LFTR would have no refueling power outages due to continual refueling

- the reactor is much cleaner: as a full recycle system, the discharge wastes from the reactor are predominately fission products, most of which have relatively short half lives compared to longer-lived actinide wastes.[6] This results in a significant reduction in the needed waste containment period in a geologic repository to reach safe radiation levels (300 years vs. tens of thousands of years)

- it can "burn" problematic radioactive waste with transuranic elements from traditional solid-fuel nuclear reactors, thus turning liability into an asset

- it is highly scalable. Small, 2–8 MW(thermal) or 1–3 MW(electric) versions are possible, enabling submarine or aircraft use

- it can react to load changes in less than 60 seconds (unlike "traditional" solid-fuel nuclear power plants), thus it can satisfy both base load and peak load power demands

- with a very high temperature reactor such as LFTR, it is possible to use very efficient Brayton cycle generating turbines.[1] The thermal efficiency from the high temperature of its operation reduces fuel use, waste emission and the cost of auxiliary equipment (major capital expenses) by 50% or more

- since the core is not pressurised, it does not need the most expensive item in a light water reactor, a high-pressure reactor vessel for the core. Instead, there is a low-pressure vessel and pipes (for molten salt) constructed of relatively thin materials. Although the metal is an exotic nickel alloy that resists heat and corrosion, Hastelloy-N, the amount needed is relatively small and the thin metal is less expensive to form and weld.

- by using liquid salt as the coolant instead of presurised water a containment structure only slightly bigger than the reactor vessel can be used. Light water reactors use pressurised water which flashes to steam and expands a thousand fold in the case of a leak, necessitating a containment building a thousand fold bigger in volume than the reactor vessel. This gives the LFTR a substantial theoretical advantage in terms of lower construction cost.

- it can be air cooled, which is critical for use in many regions where water is scarce

- fission products of a LFTR include stable rare elements such as rhodium, ruthenium, technetium, cesium and xenon, which are relied heavily on in modern electronics and industrial processes. These can be extracted from the waste. Medically valuable isotopes are also among LFTR fission products

Kirk Sorensen expects that with these advantages, LFTR technology will produce energy significantly cheaper than coal; he comments that this would make moot both carbon pricing schemes and more expensive alternative energy solutions[8] In remarks prepared for the Low-Carbon Energy Summit on 20 October 2011, Sorensen stated that "The most important thing that we can do to fight climate change is to replace coal as our primary source of electricity" and advocated the LFTR as an "even less expensive" replacement.[9] The ultimate goal is to "provide electricity for less cost than any other competing solution" which Sorensen thinks will "eventually get to 1 cent per kilowatt hour using this technology"[10][11]

Ease of reprocessing[edit | edit source]

A molten salt reactor's fuel can be continuously reprocessed with a small adjacent chemical plant. Weinberg's groups at Oak Ridge National Laboratory found that a very small reprocessing facility can service a large 1 GW power plant: All the salt has to be reprocessed, but only every ten days. The reactor's total inventory of expensive, poisonous radioactive materials is therefore much smaller than in a conventional light-water-reactor's fuel cycle, which has to store spent fuel rod assemblies. Also, everything except fuel and waste stays inside the plant. The reprocessing cycle is:

- A sparge of fluorine removes volatile high-valence fluorides as gas, including uranium hexafluoride containing the uranium-233 fuel as well as other isotopes of uranium; neptunium hexafluoride; technetium hexafluoride and selenium hexafluoride containing the long-lived fission products technetium-99 and selenium-79, as well as fluorides of various strongly radioactive short-lived fission products such as iodine-131, molybdenum-99, and tellurium-132. See fluoride volatility for boiling points. The volatile fluorides are condensed from the sparge fluorine, reduced back to less volatile lower-valence fluorides, and returned to the reactor.

- A molten bismuth column separates protactinium from the fuel salt, which is stored to allow protactinium-233 to decay to uranium-233 without being destroyed by neutron capture in the reactor. With a half-life of 27 days, ten months of storage assures that 99.9% of 233Pa decays to 233U fuel, while any 231Pa remains in the bismuth.

- The remaining fuel salt is then distilled at increased temperature and lowered pressure. The distillate is condensed and returned to the reactor.

- The light carrier salts beryllium fluoride and lithium fluoride form the bulk of the salt; individually at atmospheric pressure they evaporate at 1169 °C and 1676 °C, while the 2:1 FLiBe mixture with proportions Li2BeF4 evaporates at 1430°C. Boiling points under vacuum are lower.

- Cesium fluoride, containing the most radioactive medium-lived fission product cesium-137, boils at 1251°C under standard conditions, and will evaporate with the carrier salt fluorides.

- Thorium(IV) fluoride evaporates at temperatures about 1680 °C or less under vacuum.

- Lanthanide trifluorides and alkaline earth fluorides have boiling points higher than 2200°C under standard conditions, and would remain after thorium fluoride evaporates; the lanthanides include the worst long-term neutron poisons, while strontium fluoride contains the other major medium-lived fission product strontium-90.

The amount of waste involved is about 800 kg per gigawatt-year generated (1.5 grams/minute for a 1 GW reactor), so the equipment is very small. Salts of long-lived transuranic metals go back into the reactor as fuel. With salt distillation, an MSFR can burn plutonium, or even fluorinated nuclear waste from light water reactors.

- Theoretically, a "two-fluid" reactor design could separate the fertile thorium from the fissile fuel salts. This would eliminate the technologically challenging separation of thorium fluoride (boiling point 1680 °C) and lanthanide fission product fluorides via high-temperature distillation, at the cost of a more complex reactor. Oak Ridge researchers abandoned two-fluid designs because no good pipe materials were known to operate in the high-temperature, high-neutron, corrosive environment of a MSR core.[12]

Disadvantages[edit | edit source]

- The proposed salt mixture FLiBe, has large amounts of beryllium, a poisonous element. The salt in the primary and secondary cooling loops must be isolated from workers and the environment to protect from beryllium poisoning.

- Hot fluoride salts naturally produce hydrofluoric acid when in contact with water. When cool, fluoride salts are nearly insoluble in water. Although HF generation would be taken into consideration in the reactor's design and shutdown/decommission processes, this hazard needs to be addressed in emergency situations that damage all five levels of the reactor's containment while the salt is hot.

Design challenges[edit | edit source]

- High neutron fluxes and temperatures in a compact MSR core can change the shape of a graphite moderator element, causing it to require refurbishing in as little as four years of operation. Eliminating graphite from sealed piping was a major incentive to switch to a single-fluid design.[12]Most MSR designs do not use graphite as a structural material, and arrange for it to be easy to replace. At least one design used graphite balls floating in salt, which could be removed and inspected continuously without shutting down the reactor.[13]

- Corrosion is significant if the reactor is exposed to any isotope of hydrogen, which forms corrosive, chemically reactive, radioactive hydrogen fluoride (HF) gas. The high neutron density in the core rapidly transmutes lithium-6 to tritium, a radioactive isotope of hydrogen, which is nrealy identical, chemically speaking. In hot fluoride salts, the tritium forms tritium fluoride. Because of this, if a MSR design uses a lithium salt, it uses the lithium-7 isotope in order to prevent tritium formation. In the MSRE, Tritium formation was prevented by the removal of lithium-6 from the fuel salt via isotopic enrichment. Since lithium-7 is at least 16% heavier than lithium-6, and is the most common isotope of lithium, the lithium-6 is comparatively easy and inexpensive to extract from naturally occurring lithium. Vacuum distillation of lithium achieves efficiencies of up to 8% per stage and only requires heating of raw lithium in a vacuum chamber. This worked: No Hydrogen corrosion was found in the MSRE..[14] Practical MSRs also operate the salt under a blanket of dry inert gas, usually helium.

- The reactor makes small amounts of tellurium as a fission product. In the MSRE, this caused some small amounts of corrosion at the grain boundaries of the special nickel alloy, Hastelloy-N used for the reactor. 1974 metallurgical studies showed that this grain-boundary corrosion could be prevented by adding small amounts of Titanium or Niobium to the Hastelloy.[3]

- When cold, the fuel salts radiogenically produce corrosive, chemically reactive fluorine gas. Although a very slow process, the salts should be defueled and wastes removed before extended shutdowns to avoid (non-radioactive) fluorine gas production. Unfortunately, this was discovered the unpleasant way, while the MSRE was shut-down over a 20-year period.[15]

Recent developments[edit | edit source]

The Fuji MSR[edit | edit source]

The FUJI MSR is a 100 to 200 MWe molten-salt-fueled thorium fuel cycle thermal breeder reactor design, using technology similar to the Oak Ridge National Laboratory Reactor. It is being developed by a consortium including members from Japan, the U.S. and Russia. As a breeder reactor, it converts thorium into nuclear fuels.[16] As a thermal-spectrum reactor, its neutron regulation is inherently safe. Like all molten salt reactors, its core is chemically inert, under low pressures to prevent explosions and toxic releases.[17] It would likely take 20 years to develop a full size reactor[18] but the project seems to lack funding.[19]

Chinese Thorium MSR project[edit | edit source]

The People's Republic of China has initiated a research and development project in thorium molten-salt reactor technology.[20] It was formally announced at the Chinese Academy of Sciences (CAS) annual conference in January 2011. Its ultimate target is to investigate and develop a thorium based molten salt nuclear system in about 20 years.[21][22][23]

Flibe Energy[edit | edit source]

Kirk Sorensen, former NASA scientist and Chief Nuclear Technologist at Teledyne Brown Engineering, has been a long time promoter of thorium fuel cycle and particularly liquid fluoride thorium reactors. He first researched thorium reactors while working at NASA, while evaluating power plant designs suitable for lunar colonies. Material about this fuel cycle was surprisingly hard to find, so in 2006 Sorensen started "energyfromthorium.com", a document repository, forum, and blog to promote this technology. In 2011, Sorensen founded Flibe Energy, a company aimed to develop 20-50 MW LFTR reactor designs to power military bases. (it is easier to approve novel military designs than civilian power station designs in today's US nuclear regulatory environment).[24][25][26][27]

Small modular design[edit | edit source]

Kirk Sorensen of Flibe Energy, presenting at the 2011 Thorium Energy Conference, described how various factors influence design for small modular reactors.[28]

Neutron temperature requirements matter on two fronts. Primarily is fuel choice:

- U-235 and Th-232/U-233 work most efficiently with thermal spectrum neutrons (<1 eV)

- U-238/Pu-239 requires fast spectrum neutrons (>100,000 eV) to sustain breeding

Second is reactor size. Fast spectrum neutrons deal with a much smaller nuclear cross section, meaning that for any given distance, they are less likely to be absorbed by a fissile or breedable nucleus than thermal spectrum neutrons. This drives up the minimum reactor size for a given power level.

Operating Temperature has two basic ranges. "Moderate" is defined as 250-350 C, and is comparable to conventional Light Water Reactor and fossil plant temperature ranges. "High" is defined as 700-1000 C, which provides greater efficiency due to the higher temperature gradient with ambient, but provides challenges for material selection.

Operating Pressure can be anywhere between "Atmospheric" and "High" pressure (15.5 MPa (153 atm) for a Pressurized water reactor is considered high). These ranges are related to coolant type.

Here are four examples among the proposed small modular reactor designs, one for each temperature/pressure combination:

- Water: Moderate Temperature, High Pressure (e.g. B&W mPower, NuScale, Westinghouse,[29][30] IRIS, KLT-40)

- Gas: High Temperature, High Pressure (e.g. Pebble bed modular reactor, Gas turbine modular helium reactor, Energy Multiplier Module)

- Liquid Metal: Moderate Temperature, Atmospheric Pressure (e.g. Hyperion, Toshiba 4S, GE PRISM)

- Molten salt reactor: High Temperature, Atmospheric Pressure (e.g. LFTR)

Various conclusions about the three fuels and possible reactor types are then drawn:

Higher temperature reactors can operate at higher thermal efficiency (e.g. with Brayton cycle turbines), which is desirable. High turbine pressure is a safety concern, as the proposed turbines - using Supercritical carbon dioxide - would need to operate at over 20 MPa (195 atm). The safety concern is more industrial than radiological, however, as turbine systems are generally not built close enough to their heat generators to be a risk to them.

The main drawback of U-235 is its scarcity. Even so, most currently operating reactors use it in water-cooled reactors. Gas-based concepts (e.g. PBMR, VHTR, GT-MHR) are also feasible.

The liquid metal coolants used are poor neutron moderators, thus such systems strongly favor U-238/Pu-239 usage; adding moderators to enable use with U-235 or Th-232/U-233 would be "feasible but unattractive". Conversely, water is a good moderator and this rules out exclusive plutonium breeding in such systems. Gas-cooled systems with U-238/Pu-239 (Gas Cooled Fast Breeder Reactor (GCFR) and EM2 concepts) are described as feasible but with difficult fuel processing, while molten salt systems with U-238/Pu-239 (e.g. MSFR) are only "somewhat feasible."

Sorensen notes that while Th-232/U-233 was used in a water-cooled reactor at the Shippingport Atomic Power Station and a gas-cooled reactor at the Fort St. Vrain Generating Station, thorium dioxide fuel is "very difficult to process," making Th-232/U-233 unattractive for all systems except liquid salt, e.g. where thorium and uranium fluorides are used instead.

In Sorenson's opinion, the LFTR design combines the desirable characteristics of abundant fuel supply, high operating temperature, atmospheric operating pressure and simple fuel processing.

The Weinberg Foundation[edit | edit source]

The Weinberg Foundation is a British non-profit organisation founded in 2011 dedicated to promotion and development of a liquid fluoride thorium reactor. It was formally launched at the House of Lords on 8 September 2011.[31][32][33]

See also[edit | edit source]

- Safe nuclear power

- Integral fast reactor

- Fukushima I nuclear accidents

- Nuclear emergencies

References[edit | edit source]

- ↑ 1.0 1.1 Hargraves, Robert; Moir, Ralph (January 2011). "Liquid Fuel Nuclear Reactors". Forum on Physics & Society (American Physical Society) 41 (1): 6-10.

- ↑ [1] Robertson, R.C.; Briggs, R.B.; Smith, O.L.; Bettis, E.S. 1970. Two-fluid Molten-salt Breeder Reactor Design Study (Status as of January 1, 1968). Technical Report ORNL--4528. Oak Ridge National Lab.

- ↑ 3.0 3.1 [2] Enge, J.R.; Bauman, H.F.; Dearing, J.F.; Grimes, W.R.; McCoy, H.E.; Rhoades, W.A. 1980. Conceptual design characteristics of a denatured molten-salt reactor with once-through fueling. pp.81-89. Technical Report TM-7207. Oak Ridge National Lab.

- ↑ Section 5.3, WASH 1097 "The Use of Thorium in Nuclear Power Reactors", available as a PDF from Liquid-Halide Reactor Documents Accessed 11/23/09

- ↑ Thorium Fuel Cycle, AEC Symposium Series, 12, USAEC, Feb. 1968

- ↑ 6.0 6.1 David Sylvain, etal (March-April 2007). "Revisiting the thorium-uranium nuclear fuel cycle". Europhysics News 38 (2): 24-27. doi:10.1051/EPN:2007007.

- ↑ http://web.archive.org/web/20110220072610/http://analysis.nuclearenergyinsider.com:80/industry-insight/thorium-miracle-cure-new-nuclear-backbone?

- ↑ Kirk Sorensen: Thorium Could Be Our Energy "Silver Bullet" MP3 (first 38 min)

- ↑ Flibe Energy presentation at LCES-2011 in China and powerpoint file of slides

- ↑ http://nextbigfuture.com/2011/07/could-thorium-solve-worlds-energy.html

- ↑ Note for comparison: Electric Power Monthly (Oct. 2011) states that "The average retail price of electricity for July 2011 was 10.58 cents per kilowatthour (kWh)"

- ↑ 12.0 12.1 from Thorium blog->Reactor Design->Graphite and Two-Fluid vs. One-Fluid LFRs Viewed 6/2007

- ↑ ORNL-4548: Molten-Salt Reactor Program: Semiannual Progress Report for Period Ending February 28, 1970, p. 57

- ↑ W.D. Manely et al. (1960). Metallurgical Problems in Molten Fluoride Systems. Progress in Nuclear Energy, Vol. 2, pp. 164–179

- ↑ Evaluation of the U.S. Department of Energy's alternatives for the removal and disposition of molten salt reactor experiment fluoride salts, National Research Council (U.S.). Committee on Remediation of Buried and Tank Wastes. Molten Salt Panel, National Academies Press, 1997 ISBN 0309056845 p. 15

- ↑ Fuji MSR pp. 821–856, Jan 2007 20MB PDF

- ↑ FUJI Reactor, in the MSR article of the Encyclopedia of the Earth

- ↑ Fuji Molten salt reactor, December 19, 2007

- ↑ Fuji Molten Salt reactor, Ralph Moir Interviews and other nuclear news, March 19, 2008

- ↑ Martin, Richard (2011-02-01), "China Takes Lead in Race for Clean Nuclear Power", Wired Science

- ↑ http://web.archive.org/web/20130602105426/http://whb.news365.com.cn:80/yw/201101/t20110126_2944856.htm

- ↑ http://www.cas.cn/xw/zyxw/ttxw/201101/t20110125_3067050.shtml

- ↑ http://www.guardian.co.uk/environment/blog/2011/feb/16/china-nuclear-thorium

- ↑ http://flibe-energy.com/

- ↑ http://nextbigfuture.com/2011/05/kirk-sorensen-has-started-thorium-power.html

- ↑ http://www.guardian.co.uk/environment/blog/2011/sep/07/live-web-chat-nuclear-kirk-sorensen

- ↑ http://www.huntsvillenewswire.com/2011/09/27/huntsville-company-build-thoriumbased-nuclear-reactors/

- ↑ Presenting at ThEC2011 and powerpoint file of slides

- ↑ Westinghouse SMR

- ↑ Westinghouse announces Small Modular Reactor

- ↑ http://www.guardian.co.uk/environment/blog/2011/sep/09/thorium-weinberg-foundation

- ↑ http://www.mynewsdesk.com/uk/pressroom/the-weinberg-foundation/pressrelease/view/london-weinberg-foundation-to-heat-up-campaign-for-safe-green-nuclear-energy-678919

- ↑ http://www.businessgreen.com/bg/news/2107710/ngo-fuel-safe-thorium-nuclear-reactors

External links[edit | edit source]

- EnergyFromThorium.com - Blog / Website about LFTR with document repository and discussion forum

- Thorium Energy Alliance - advocacy and educational organisation dedicated to thorium energy

- International Thorium Energy Organisation

- Google TechTalks – Liquid Fluoride Thorium Reactor: What Fusion Wanted To Be by Dr. Joe Bonometti NASA / Naval Post Graduate School - YouTube video

- Thorium Remix 2011, a video describing the thorium fuel cycle and LFTRs

- Motherboard TV: The Thorium Dream documentary

- Telegraph article: Obama could kill fossil fuels overnight with a nuclear dash for thorium

- Forbes article: Is Thorium the Biggest Energy Breakthrough Since Fire? Possibly.

- Wired article: Uranium Is So Last Century — Enter Thorium, the New Green Nuke

- Flibe Energy company website

- Thorium and LFTR Top Ten Attributes (a talking points memorandum by Flibe Energy)

- Weinberg Foundation website