Background[edit | edit source]

"The Full Belly Project designs and distributes income-generating agricultural devices to improve life in developing countries." (http://www.fullbellyproject.org/) Jock Brandis developed a Universal Nut Sheller that decreases manual labor and increases total well being of communities. Our assignment was to modify the design in order to make it suitable for the United States market. The proceeds will benefit the Full Belly Project's mission.

Abstract[edit | edit source]

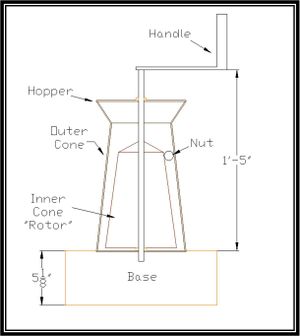

The Simple Simon consists of three main parts: The outer cone, the rotor and shaft with a handle, and the base.

Outer Cone:

The outer cone is made of a 3/16 inch aluminum sheet cut into a shape that allows it to be wrapped into a truncated cone.

Rotor and shaft with handle:

The rotor is a truncated cone made of solid wood. The shaft is located in the center of the rotor. The handle is connected to the shaft for leverage and ease of use.

Base:

The base is a simple box with a raised disc. The raised disc enables the outer cone to be latched in place. A cylindrical hole in the center holds the shaft to minimize wobbling.

Costs[edit | edit source]

Materials[edit | edit source]

| Item | Quantity | Unit Price | Retail Cost | Our cost |

|---|---|---|---|---|

| Aluminum Sheet | 1 | 40.00 | 40.00 | 40.00 |

| Yarn | 1 | 1.39 | 1.39 | 1.39 |

| Poster Board | 4 | 0.99 | 3.96 | 3.96 |

| Theraded Rod | 1 | 6.49 | 6.49 | 6.49 |

| Bolts | 2 | 0.50 | 1.00 | 1.00 |

| Washers | 2 | 0.40 | 0.80 | 0.80 |

| Wood Glue | 1 | 4.95 | 4.95 | 4.95 |

| 1x12 wood blocks | 3 | 1.10 | 3.30 | 3.30 |

| 6x12 wood | 4 | 4.50 | 18.00 | 18.00 |

| Total | 79.89 | 79.89 |

Possible alternative materials[edit | edit source]

For our project we were unable to manipulate the aluminum, so instead we used plexi glass in place of the aluminum. The inner rotor could also be made out of aluminum.

Tools[edit | edit source]

This project needed a variety of different types of tools including: a machine lathe, a press drill, a heating oven, a hammer, a saw, etc.

Skills needed[edit | edit source]

A good amount of machinery operation experience is need. This is because it is hard to construct this project without knowing how to use some of the mentioned tools above without experience.

Estimated time of construction[edit | edit source]

If one was to make this project by them selves, the construction can take about a week. This estimate includes drying times needed to set the glue.

Specifications[edit | edit source]

Our solution, the Simple Simon, is based on the original Full Belly Universal Nut Sheller design which can be seen in figure 1. The Simple Simon is constructed out of aluminum and wood. The outer cone is aluminum and 12 inches tall with upper and lower diameters in ratio with the original full belly design seen in figure 1. The upper diameter of the outer wall is 5.45 inches. The base is 8.21 inches. The gradient of the outer cone is 83.4 degrees. The inner cone is fabricated out of hard wood and has a height of 5.82 inches with an upper diameter of 5.52 inches and a base diameter of 7.60 inches. The gradient of the inner cone is 80 degrees. The axle runs through the center of the inner cone and extends up through the outer wall where it is attached to a hand crank. Both the inner and outer cone anchor into a hardwood base board 12 inches x 12 inches x 1 inch. A cylinder with a diameter of 7.9 inches and a height of 1 inch extends upward from the base board to provide the outer cone with inner support.

Construction instructions[edit | edit source]

1.Outer Cone

A Get a piece 12X12" piece of wood and put it into lave, specifying the larger radius to 4 5/8", and the top radius to 2 6.75/8". Make the distance between the circles 12"

B Get a 1" thick piece of aluminum with the dimensions of 30X13". Cut it out with a top arc length of 17.9" and a bottom arc length of 26.577" with 12.01 inches between the two arcs. c.Clamp aluminum down to the wooden outer cone mold and bend it around the cone using the sheet metal roller. Weld the edges together.

2.Inner Cone

A. Get a piece 12X12" piece of wood and put it into lathe, specifying the larger radius to 4 5/8", and the top radius to 2 6.75/8". Make the distance between the circles 12"

B. Drill hole through the center of the cone and screw in threaded rod with diameter of 1/2" through it(height). Fasten 8 7/8" long handle to thread and using 1/2" bolts to hold it in place. Secure the inner cone onto the axle by welding it in place

3.Base

A. Get 4 pieces of plywood that have a width of 1' 5/16" and a height of 5 1/8" and two pieces of ply wood that are 1' 5/16" by 1' 5/16". Each piece of wood should be 1" thick.

B. Use one of the pieces of plywood with the 5/16" and a height of 5 1/8" and turn it into a sliding door that will serve as the removable nut catcher. In order to do this you must use 4 more pieces of wood, three serving as the walls of the catcher, and one as the base. The Walls should have a height of 4 1/8" and width of 11 11/16". and the base should be 11 11/16" by 11 11/16". the wall of the cabinet should be indented an inch inward from the wall that is going to face the exterior to make sure that the outer wall is flush with the others when closed.

C. With one of the pieces that were 1' 5/16" by 1' 5/16" cut 4 squares out of the center that are 4 1/8" by 4'1/8 inches with 5/8 " gaps in between each square, making the 4 squares 90 degree corners concentric to that of the outer wood panel.

D. Nail the top, the three sides, and the bottom together, and slide in the catcher on the side that open

Next steps[edit | edit source]

Refine the overall design to make it more marketable, economical, and easily produced.