The construction of the DIF senior center in Parras began in 2006 after DIF approached Cal Poly Humboldt to request assistance with the project. DIF hopes to provide a center for activities for the elderly within the community; this stems from a desire to physically and mentally stimulate the elderly community of Parras in order to promote healthier lifestyles. This year´s work will involve finishing the pouring of the foundation for the kitchen, which was added to the floor plan last year. Also, this year will entail constructing the kitchen walls with adobe, leveling out the partial walls that were built in past years, building up the walls to a greater height, minor repairs for problems caused by weathering, and completion of the structure, including the roof.

This is the third year that the Cal Poly Humboldt Appropriate Technology Program in Parras has worked on this project. Our group feels optimistic about finishing the project this year. We have created a day by day breakdown and are currently on schedule with where we should be in terms of work. The group is compromised of four people: Tonya Netjes, Daniel Hernandez, Joel Janson, and Kristin Gierman. With our diverse work backgrounds, our talents compliment each other and we are a well-functioning group.

Background[edit | edit source]

This was the status of the site when we first arrived:

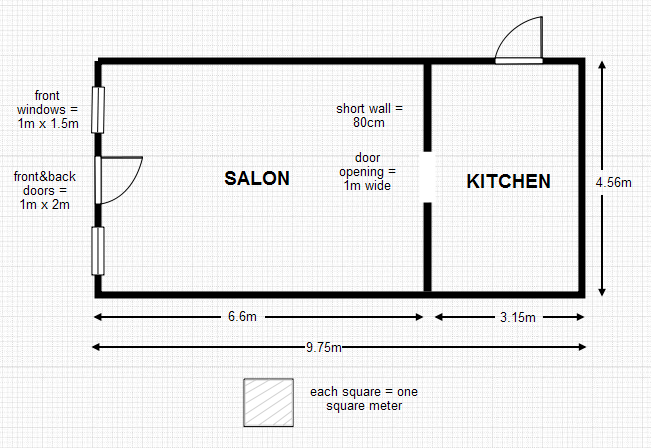

This is the floor plan for the structure we are working on. It was modified in 2007 to include a small kitchen.

Objectives[edit | edit source]

Our objectives are to learn the tradition of adobe, provide a service for the community with the community, finish the project and construct not only a building but a permanent relationship between Humboldt and Parras

Criteria[edit | edit source]

| Criteria | Weight (0-10 highest) |

|---|---|

| Leverages existing knowledge (doesn´t reinvent the wheel) | 7 |

Locality:

|

8 |

Culturally Sensitive

|

10 |

Economically Appropriate

|

8 |

Responsible Design

|

10 |

Budget[edit | edit source]

| Materials | Cost (Pesos) |

|---|---|

| Cuchara | $150.00 Pesos |

| Esquadra | $95.00 Pesos |

| 4 Pacas de Paja | $155.00 Pesos |

| 1 Plomada | $100.00 Pesos |

| 1 kilo de Clavos | $15.00 Pesos |

| 2 Kilos de Alambre (Metal Wire) | $74.00 Pesos |

| Castillos (Rebar beams) | $380.00 Pesos |

| Calling Card | $50.00 Pesos |

| Transportation of Vigas (Gas to Luis) | $100.00 Pesos |

| Transportation of Bales (Gas to Chano) | $100 Pesos |

| Total | |

| (Personal Expenses Not included) | $1200.00 |

Timeline[edit | edit source]

Week 1[edit | edit source]

Daniel Hernandez, Joel Janson and Tonya Netjes were assigned to work on the 2008 DIF Adobe Building Squad.

A trip was taken to DIF to see the site that had been worked on for two years prior.

Many adobes were stacked up on site from the past years.

First, we removed all trash from the site.

-

Fig 1: wood pallets, which we later broke down for lumber

-

Fig 1a: broken furniture and trashed construction material

-

Fig 1b: adobe bricks from previous years, some unsuitable for building

-

Fig 1c: we broke down the unsuitable bricks in a pit to make mud

Then, we met with Ciro Liro, our adobe instructor who was appointed by DIF. We took measurements with Ciro and created plans and a projected timeline for our project.

Proposed Process:

- Pour cement for kitchen foundation

- Make adobe bricks (150-200) and set up for drying

- Construct slip/mud pit and make slip/mud

- Transport adobes to work site

- Begin constructing Kitchen with adobes and slip

- Construct cement dalas (roof support) around the rim of house

- Set up vigas (wood beams) and weave carizo (first roof layer)

- Complete the roof using layers of different materials.

- Apply final layer of finish to the walls.

-

Fig 1: Making initial plans with Ciro Liro

-

Fig 1a: Envisioning the completed structure

-

Fig 1b: Daniel, assessing the situation

-

Fig 1c: Gaps between the existing adobe walls & a bordering structure

Daniel Hernandez had worked with natural building in the past and knew that we would have to create a mud pit in order to have an adhesive substance (mud!) to have our adobes stick together as we built up our walls. The pit was created by building up a wall in the shape of an oval two feet high out of last year's adobes. A plastic tarp was laid down on the bottom of the pit to hold in any water poured inside. By smashing adobes (not usable for the house) with a pulaski, we have managed to get a good dirt for our mud. We danced in the pit with bare feet and mixed the water and dirt to break down the mud into the very consistency we needed.

-

Fig 1: setting up the pit

-

Fig 1a: a plastic tarp was used to avoid water loss via leeching into the soil

-

Fig 1b: we used trash from the site to divert the water into the pit

-

Fig 1c: the water needed to saturate into the bricks of compressed earth

The foundation for the kitchen was ready for us to pour cement into.

-

Fig 1: Last year´s group laid down a frame using adobe bricks

-

Fig 1a: We had to clean out the frame and level it out

-

Fig 1b: The corners must be carefully poured as they will support the structure

-

Fig 1c: The groundwork for our future kitchen!

The previous group left us with a bag of cement and DIF gave us access to more. The government of Coahuila implemented a new program that gave away certain materials for free, such as cement, if the house adheres to certain standards. Our house met these standards and therefore we received 5 bags that were transported by DIF. Daniel and Joel immediately set to work mixing it assuming that Daniel´s experience would hold enough guidance for adding the proportions of materials correctly. We used 3 bags of cement and completed half of the kitchen foundation. The next day, mixing with different proportions, we poured the second half using 1 bag of cement.

During our first weekend, we were all involved in a festival of Cinema of the Desert, held in Parras. Because of this commitment, we lost some work time, but made more plans for the next week.

Week 2[edit | edit source]

This is the week that we were involved in an academic conference here in the desert. Because of the high level of commitment required for conference participation, we only had 2 days to work this week.

Kristin jumped on board. As a videographer, she planned to be filming and editing videos to add to this website so that another media could be shared in order for others to understand and learn the process of adobe making.

Ciro Liro, the main teacher of the last two years became unacceptable in our eyes, and we replace him with a man named Juan. Juan showed up at the work site almost every day and began to teach us how to construct and make up for past mistakes with an inspiring zeal.

On the weekend The class gathered at La Casa Vieja (restaurant and friendly residence) anticipating a sweaty, endorphin filled day of adobe making in the back yard (la huerta.) Juan took up the helm, instructing the students and spreading paja/hay over a carved out area of naturally mixed clay and sand. We chopped it little by little into consistent material, ready to be encased in adoberas and set out to dry. By the end of day 2, our labor had produced 200 adequate bricks.

-

Fig 1: La huerta where we made adobe, behind Casa Vieja

-

Fig 1a: chopping the mixture, poco a poco

-

Fig 1b: Our beautiful adobe bricks, in the initial drying stage.

-

Fig 1: Linsey and Ryndie pushing the mud mixture into the adobera, or frame

-

Fig 1a: The adobe bricks, propped up on the second day to dry faster.

-

Fig 1b: Bricks drying, people working

-

Fig 1c: Packing mud into adoberas

Week 3[edit | edit source]

During this week, we continued building the walls up with the bricks remaining from previous years. We also went to visit the new adobes to turn them on their thin sides for drying. That process required us to scrape off all excess dirt which had attached itself to the bottom of each brick. At the end of the week we transported one truckload of adobes from La Casa Vieja and used them to finish the back right wall.

-

Fig 1: building our first wall

-

Fig 1a: Making sure the wall is straight

-

Fig 1b: Juan teaching us how to build our first wall

-

Fig 1c: The wall that will act as a door frame.

We decided to use an existing wall for the back wall of the kitchen, since building a second wall a few inches away from the first would not be structurally safe or realistic, considering rainfall patterns and safety issues. To use this wall, we first had to level out the top of it so that we could add more adobe bricks to increase the height. Then we connected the other partial wall we had built to this older back wall, using overlapping bricks to form a strong corner.

-

Fig 1: We also used a plumbob to make sure that our walls were straight.

-

Fig 1a: We placed a thick mortar between each layer of bricks

-

Fig 1b: The beginning of our last wall

-

Fig 1c: The last wall, finished.

Week 4[edit | edit source]

At the beginning of week 4 we had another day to utilize the entire class. Our original transport didn´t show up in the morning so we put a few people to work mixing mud, and the rest went to Casa Vieja to begin transporting adobe bricks. Our friend Luiz let us use his truck for the job, and soon every brick was moved safely to DIF. While Tonya and Daniel directed the laborious movement of vigas, Joel showed a few people how to build walls and set them to work adding height to the older walls. Once the vigas were moved we went to la huerta of Adrian (a DIF tourism director) to pick up packs of carizo.

The remainder of the week consisted of avoiding rain and building walls. One of the windows had been destroyed because it was in such bad shape, so we filled in that part of the wall.

-

Fig 1: Our supplies. Vigas are the small trees used for beams in the roof.

-

Fig 1a: Carizo, a type of bamboo, bundled together for easy transport

-

Fig 1b: Unpeeled, dried carizo

-

Fig 1b: Peeled, dried carizo

Week 5[edit | edit source]

Although our goal had been to finish the roof, we realized that it was pretty much impossible at this point. Our new goal was to complete the dalas that would support the roof and leave it for future groups to finish. We found a guy who lent strips of greased wood made for dalas and bought 9. We learned how to build dalas, nailing two strips together using smaller pieces of scrap wood and placing one of the doubles on each side of the adobe, making a mold for cement. Juan had showed us how to make a makeshift dala out of scrap wood but the cement came out uneven and it needs to be destroyed or built over.

-

Fig 1: Our first dala, made of scraps of wood and random trash. bad idea.

-

Fig 1a: We tried to pour the concrete so that it was level,

-

Fig 1b: but the dala was sagging, and so was the concrete.

There was a final day to utilize the class and we used it to build the dalas on the entire right wall and peel all of the carizo. More wood strips were needed so we rented another 10. We leveled the dala so that it would slope forward a little bit. The purpose of that was to make sure the roof would not hold rain, but then we realized this was a process that should be done with adobe bricks while building the roof. In the last days we built and mounted almost all of the dalas, at which point we were told by some professional construction workers that they could not be used. We took them down and brought the wood back to the owner.

-

Fig 1: Using rented wood to build a more secure dala

-

Fig 1a: We included strong supports, nailed into the wall beneath the dala, to strengthen the dala

Analysis[edit | edit source]

After our five week building experience, the DIF senior center still was not finished. Although we are disappointed that we didn't reach our goal, we have learned a great deal about earthen building and working within a team. Also, we feel more secure in knowing that the roof will be built properly, eliminating many safety concerns. We encountered some communication issues in the beginning and believed that this was a natural occurrence, especially within a larger group. Together, we overcame communication boundaries by making decisions through group consensus and addressing issues as a group, as soon as they came up.

What We Would Do Differently[edit | edit source]

We would hire one expert, possibly through la Presidencia, to work with us from start to finish, giving advice on every part of the building process, including time required for each step of the process. Also, we would make more adobe bricks, just to have extra, because we almost ran out this semester.

Next Steps[edit | edit source]

El Techo: The Roof

Materiales necesarios para el techo (Necessary Materials for the roof):

- 27 Vigas (27 beams-the small trees)

- 650 carrizos-50 por cada metro) (650 bamboo stalks-50 for each meter)Br> -Cal 10 bultos (10 sacks of Cal, a mineral that is stored like cement)

- 2 metros cuadrazos de arena fina-paraenjare o plantilla (2 meters of fine sand)

- Ule-460 por 9.70 metros (Ule=plastic tarp-type covering)

- Alambre recosido (wire)

- Inpermibilizante (impermeable substance, such as animal fat)

Procesó para construir el techo (Process for building the roof):

1)Asegurar que las dalas queden completa mente forradas de cemento(Tablas)

2)Completar y asegurar que las paredes lleguen a (X) estatura Y estén bien parejas.

3)Entabicar vigas (just like brick).

4)Amarar cariso (Tapestry).

5)Poner el ule.

6)Poner torta.

7)Mesclar y applicar Plantillia (cal, cemento, y arena)

8)Pretil- roof border of 3-4 adobes

9)Enjare

10)Impermeable layer.