Nepal possesses extreme geographical conditions ranging from high hills and mountains to areas of flat land known as the terai. Rugged terrains, unfavourable weather conditions and scattered settlements in the hilly and mountainous regions obstruct the mobility of people and the transporting of goods and services as well as hindering development efforts. Rural access is a major problem in Nepal. Settlements are scattered, with few densely populated areas.

In such a harsh mountainous region the construction of roads is expensive and timeconsuming. The cost of transporting construction materials by is high, and damage from landslides is common. The gravity ropeway is therefore a viable alternative in many locations.

Practical Action Nepal commenced its transport programme in 1998. It improved and promoted innovative transportation systems, such as cable river crossing bridges known as tuin, gravity ropeways for hilly and mountainous regions and bicycle ambulances and trailers for the terai regions.

Ropeway transport has been in use in Nepal for many years. In its most basic form it consists of a single span made with fibre rope, simply anchored at each end. The first major ropeway in Nepal was installed in the 1920s, followed by an improved and extended system in 1964. Although there has been some stagnation in the development of large-scale ropeways, smallscale systems remain economically feasible in the country.

Practical Action has also been instrumental in setting up a National Forum for Rural Transport and Development, under the International Forum for Rural Transport and Development (IFRTD) umbrella.

Ropeways[edit | edit source]

Gravity ropeway technology was transferred from Northern India to Nepal by Practical Action Nepal in collaboration with the International Center for Integrated Mountain Development (ICIMOD). In partnership with ICIMOD and a private manufacturer-supplier, Practical Action Nepal installed a couple of demonstration ropeways in Marpha and Tukche VDCs of Mustang district to facilitate the transportation of apples from orchards to the road-heads. After a successful intervention in Mustang, Practical Action Nepal installed the Janagaon- Bishaltar Ropeway in Benighat VDC, the Hadikhola-Chiraudi Ropeway in Kalleri VDC of Dhading district, and the Torisawara-Bishaltar Ropeway in Torisawara VDC of Gorkha district (with financial support from The European Union, and UK Trusts and Foundations).

An initial study showed that the transportation cost of agro-based products decreases by at least 50% once served by a gravity ropeway system. Such encouraging statistics have villagers the confidence to supply their products in larger amounts, and to enter competitive city markets. Access to a transportation system and to market linkages improves their socioeconomic status in terms of income, health, education and community awareness. Promotion of this technology also helps the local economy by creating employment opportunities and by supporting local manufacturers and service providers.

The Principle[edit | edit source]

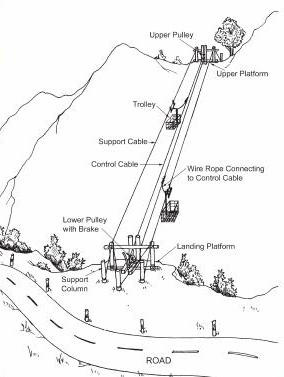

The gravity ropeway is an inexpensive and simple means of transportation. It operates by gravitational force without the use of external power. The gravity ropeway consists of two trolleys which roll on support tracks. These are attached to a control cable in the middle which moves in a traditional flywheel system. When the loaded trolley at the up-station is pulled downward by the force of gravity, the other trolley at the bottom-station is pulled up automatically by means of the control cable. In principal the goods coming downward from the up-station must to be thrice as heavy as the up-going load. The sliding down of the trolley and its speed depends upon the angle of elevation made by the cables installed with the horizontal ground.

A flywheel with bearing and bracket is used as a brake to control the landing speed of the trolley at the bottomstation. Communication between top and bottom stations is done by tapping the wire rope. The operator at the topstation strikes the wire rope with a stick to send a wave signal through the wire rope to the operator at the down-station. The operator at the down-station then applies the hand brake to control the flywheel.

Cost[edit | edit source]

The cost primarily depends upon the local topography, angle of inclination, the ropeway span at inclination between the two stations, and use of local raw materials and construction technology.

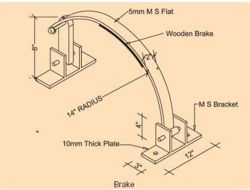

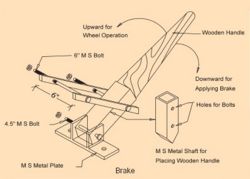

Braking system[edit | edit source]

The braking system is used to control the speed of the trolley during landing at the down platform. This is done by applying force to the handle. Brake strips are connected to a fixed support at one end, and to the brake handle at the other end.

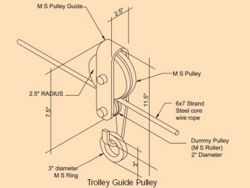

Trolley guide pulley system[edit | edit source]

The trolley guide pulley system guides and provides cushioning effect to the support wire rope, as well as converting gravitational force into kinetic energy. The system consists of a pulley guide and a dummy pulley attached to the supporting channel. The wire rope slides between the two pulleys. The ring connected to the trolley hanger is also attached to the pulleys.

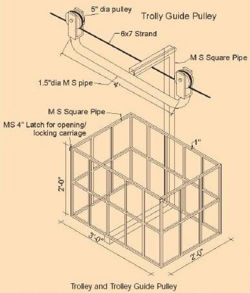

Trolley[edit | edit source]

The trolley is made from mild steel (MS) pipes, and has a hanging trolley box where the load is placed. The flexible supporting hanger is connected to the guide pulley system. Its weight should be as light as possible – say, 30 kg. The center of gravity of the trolley should be wellbalanced during operation.

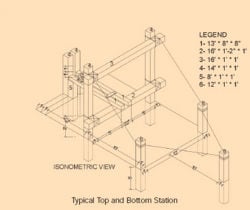

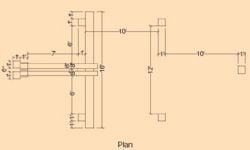

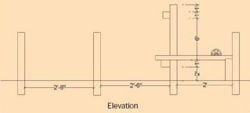

Up- and down-station platforms[edit | edit source]

The up-station and the down-station platforms are civil foundations housing the control pulley, the supporting cable, the braking system and other functioning structures. Both stations are used as loading and unloading platforms. The civil structure and foundation should be stable enough to bear all the impact and operating load of the system. This can be constructed of dry timber, iron beams and/or concrete structures, depending upon availability of raw materials and technology. Concrete construction makes the structure more stable, which in turn allows the ropeway alignment to be stable.

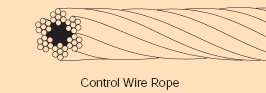

Support and control wire rope[edit | edit source]

Specifications[edit | edit source]

- 6x7 strand steel core F 10-12mm wire rope for support cable

- 6x7 strand jute core F 8-10mm wire rope for control cable

- The factor of safety should be at least 3 or more

T = (((2 * W + w * L + Ww * L) * l) / (8 * b)) / Cosß where,

T = Total load on the cable

W = Weight of loaded trolley (kg)

Ww = Wind load factor (kg/m2)

w = specific weight of wire rope (kg/m2)

ß = cable inclination with saddle point

L = l [ 1 + 0.5 * { (h / l)² } + 8/3 * { (b / l)² } ] + Lb

b = l*h / (8*e-4*l)

where,

L = Total length of the wire rope

b = Sagging at mid-way from highest point

e = Lowest point horizontal distance from highest point

l = Horizontal distance

h = Vertical distance

Lb = Backstay length at up station and down station

Functions and components of the gravity ropeway[edit | edit source]

Top-station control pulley[edit | edit source]

The top-station control pulley is used to control and guide the control wire rope at the topstation. It is supported at the end by two bearings, and the housing is fixed rigidly on the base frame of the platform.

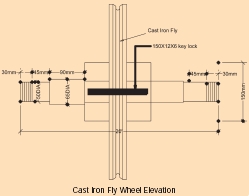

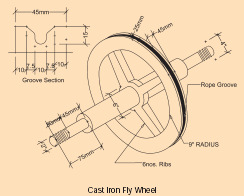

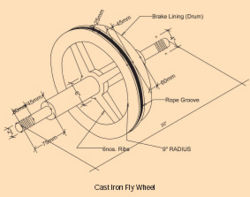

Down-station control pulley and fly wheel[edit | edit source]

The down-station control pulley and fly wheel are used to control and guide the control wire rope at the down-station. They are supported at the end with two bearings, and the housing is fixed rigidly on the base frame of the platform. The fly wheel ensures smooth motion along the wire rope.

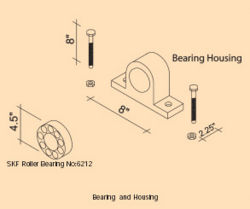

Bearing and housing[edit | edit source]

The bearing and the housing are used to support and provide free movement to the shaft, which contains the control pulley. For this purpose, an SKF Roller bearing No. 6212 (with corresponding bearing housing) are used.

Tuin[edit | edit source]

Wire Bridges (Tuin) are an indigenous technology, and one of the most common structures for river crossing in the hilly regions of rural Nepal. There are more than 6000 rivers in Nepal, most of them with no means of crossing. Many people die trying to cross during the monsoon season. There are more than 15 tuin in operation along the Trisuli River, each one serving approximately 50 households (300 people).

The new design of tuin[edit | edit source]

Practical Action Nepal has conducted a study looking to improve the existing technology. Ideas for improving the design came form the local community during discussions with Practical Action technical experts. The community expressed concerns about the safety of traditional tuins. Many people have lost fingers while operating tuins, and there also is the danger of falling out of a trolley while crossing a river. Practical Action has come up with lowcost improvements that address users' concerns.

One of the first changes was to develop a safe trolley to prevent people falling out. Seats were added and sidebars installed. Practical Action Nepal then went on to develop a new pulley system that makes pulling the trolley easier and eliminates the risk of trapping fingers in the mechanism. The pulley and bearing system also reduces friction and lessens the effort required to cross the river, doubling the overall efficiency.

The improved tuin was developed and tested at the village of Mahestar (about 60 km west of Kathmandu). Based on the experience gained here, the design has been further developed into a double-cable design. Although costing more it provides better balance and can carry a greater load. Double-cable prototypes have been built in the villages of Kalleri, Pimaltar and Balkhu, in Nepal's Dhading district.

The costs involved in the construction of an improved tuin are:

- labour

- manufacturing

- tuin support system (pillar construction)

- wire cable

- tuin trolley

- pulley system

- anchor block and other accessories

- installation

- equipment transportation

The improved tuin is intended for areas where other forms of river-crossing are inappropriate or too expensive.

Reference[edit | edit source]

- An Evaluation of a Micro-hydro Powered Ropeway in Nepal A. L. S. Duignan, Centre for Environmental Technology, Imperial College of Science, Technology & Medicine, University of London, 1998.

- Ropeways in Nepal: Conceptual Analysis of Context and Viability, Interdisciplinary Analysis, ITDG Nepal, 1996.

Further information[edit | edit source]

Service Providers[edit | edit source]

For wire ropes of ISI standard

Usha Martin Industries Limited

14 Princep Street, Calcutta 700 072, India

Tel: 27-2203

For wire rope accessories

Navin Steel Industries

Dhangu Road, Pathankot – 145001, India

Tel: 01893-244690, Fax: 01893-24408

Installation Support

Ambika Fabrication and Repairing Pvt. Ltd.

Bhaktapur, Katunje, Ward No. 9, Sallaghari,

Tinkune

Ph: 977-1-6610353

Contact Person: Doordam Thapa

Cell Ph: 9851052853

Structo Nepal Pvt. Ltd.

P.O. Box: 228, Block No. 27,

Patan Industrial Estate, Patan

Ph: 977-1-5521192, Fax: 977-1-5542118

Contact Person: Rajendra Pradhan

Practical Action Nepal

P.O.Box 15135

Kupandol

Lalitpur

Kathmandu

Nepal

Tel: 977-1-4446015/4434482,

Fax: 977-1-4445995,

Email: info@practicalaction.org.np

Email: practicalaction@practicalaction.org.np

www.practicalaction.org

International Forum for Rural Transport and Development

IFRTD

2 Spitfire Studios

67-73 Collier Street

London N1 9BE

United Kingdom

Tel: +44 (0)20 7713 6699

Fax: +44 (0)20 7713 8290

Email: ifrtd@ifrtd.org

Website: http://www.ifrtd.org

The International Forum for Rural Transport

and Development is a global network of

individuals and representatives from

government, academia, multilateral and

bilateral donor agencies, consultancies and

technical institutions, national and

international NGOs and groups of community

organizations.

Nepal Net

an electronic networking for sustainable

development in Nepal

http://web.archive.org/web/20040911044220/http://www.panasia.org.sg:80/nepalnet/technology/

hydro_trans.htm

Appropriate Technology Development and

Goods Manufacturing Industries (ATDGM)

Balaju Industrial Estate,

Balaju, Kathmandu

Tel: 977-1-4356191

Email: shankar@manjee.wlink.com.np