Abstract

The goal of this page is to present the design, plans, implementation, maintenance and use of the the concessions cart stand made by group TBD. Background information and understanding of the concession cart project will be covered first, followed by a description of the problem, criteria, and prototyping process. Cost and maintenance will be the last sections of this page.

Background

Zane Middle school is located in Eureka, California aiming to inspire academic Excellence, Creativity, and the Confidence to Succeed. They provide their students with a number of extracurricular activities like golf, girls volleyball, soccer, basketball, cheerleading, track, and wrestling; an extraordinary After School Program, and these are just a few on a long list. A lot of these activities provide snacks and water to the attendants and students. The transportation and storage of this food is where the intrepid designers from Humboldt Sate University (HSU) come in. Team The Best Designers consists of four students attending HSU's Engineering 215, Introduction to Design course of Spring, 2019. Closely working with our client, Danielle Muniz in Zane Middle School, we set out to design a concessions cart stand that would make the transportation and storage of food easy and convenient.

Problem statement and criteria

The issue that Team The Best Designers set out to address was the storage and transportation of snacks and drinks for school events. The school had been previously setting up tables and providing the food from there. The set up and movement of the tables can be a hassle because of the possible strains of lifting or the excess work that comes with setting up an area. With the implementation of a cart, the transportation, set up, and storage of an area that can provide food would be completed can be completed in a few easy steps.

The Criteria was developed by Team TBD and reviewed by the client. The following is a table demonstrates its specifications.

| Criteria | Specification |

|---|---|

| Cost | Must Cost Under $400. |

| Storage | Must be able to fit through doorways 32-36in. |

| Function | Provide optimal amount of storage space for concessions. |

| Durability | Must be able to withstand long term use with children. |

| Maneuverability | Able to traverse tight corners and small spaces. |

| Safety | Must be safe enough to be handled by children. |

Description of final project

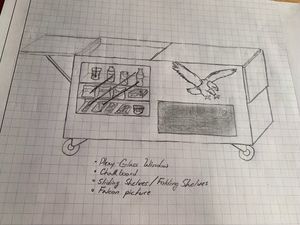

Falconstein, is a food concession cart that with help to alleviate to load of food and beverages that the existing cart made by a previous Engineering 215 group. It provides adequate storage capacity for storing food. Utilizing sliding shelves to maximize counter space when in use and easily stored for moving through tight doorways and halls as well as traversing corners. Implementing swivel as well as locking caster wheels to maneuver easily and Place in hard to get areas.

Slide Outs

The cart contains a slide out shelf on right side. Its purpose is to provide the cart with more surface area when stationed, allowing for more items to be placed on top of the cart. The adding of available space to the cart was an important consideration during its design and this table helps address that. The slide out shelf is convenient and easy to use, this process is described in the Instructions section of this page.

Slide out extended

Window & White Board

The decision to place a widow was to increase the presentation of the food. The white board serves as a price setting tool and can be easily changed.

Front view of cart where the plexiglass window and white board can be seen

Locking Caster Wheels

Applying locking caster on any swivel movement system is an effective way to stabilize and prevent unwanted movement while moving the cart.This cart has four full swivel caster wheels which give the cart the ability to move in any direction with very little effort from the user. The two back casters have a locking mechanism which fix the wheels in only one direction. This is so the cart is easier to move when being transported, giving it maneuverability similar to a shopping cart where the front wheels are free to move in any direction but the back wheels are fixed in a forward direction.The locking caster wheels are 3-inch diameter wheels comprised of a hard rubber and metal guiding system.

The ability to turn the cart from four full swivel caster wheels to having two directionally locked wheels in the back was to serve two purposes. having fixed wheels in the back makes it easier to move the cart around when moving the cart a distance more than a few feet. when the back wheels are locked the cart will be easier to control, giving it maneuverability comparable to a shopping cart. When the locks are not applied the cart will be able to be moved in any direction, this is so it is able to be moved into area like corners or have the free directional movement to be pushed up against a wall. The levers on the locking casters are painted yellow to better distinguish between the brakes and the locking mechanism.

Prototyping

|}

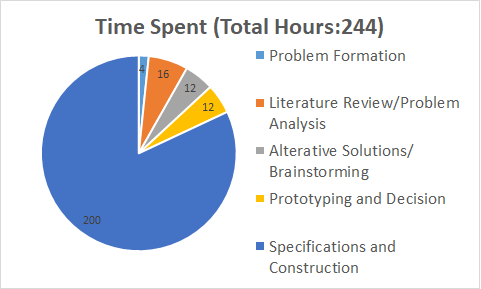

Costs

The cost of this project are demonstrated in two different ways. First is the monetary cost of the project; second is the cost in terms of time. The total cast was $318.94 and this project took a totoal of 244 hours.

Cost in Dollars

This First Tables demonstrates a list of item with it's respective cost. The (*)symbol next to an item is to signify that that item was donated and was of no monetary cost to team TBD.

| Cost Table | |||

| Quantity | Material | Source | Total ($) |

|---|---|---|---|

| 2 | PLywood | Piersons | 50.00 |

| 2 | 2.5 quart bucket | Ace Hardware | 15.00 |

| 6 | studs | Piersons | 3.33 |

| 1 | Screws (box) | Piersons | 12.00 |

| 4 | Casters | CasterHQ.com | 7.99 |

| 1 | Painting Tarp | Piersons | 7.00 |

| 2 | Paint Brushes | Ace Hardware | 13.50 |

| 1 | Spray Paint | Ace Hardware | 9.50 |

| 4 | Aluminum Frame Bars | Ace Hardware | 22.00 |

| 1 | PLexiglass | Ace Hardware | 17.00 |

| Total Cost | $342.44 | ||

Cost in Hours

The diagram bellow demonstrates the cost in hours for team TBD. Between the four group members a total of 244 hours was spent on this project. The sections of the diagram represents a specific phase of design process.

Testing Results

A successful test of the cart relied on four main factors, safety, maneuverability, appearance, and storage. These factors have the biggest impact on the use of our cart.

Safety was accomplished by through a number of ways. The following steps were taken to assure safety: Assuring there was no loose bolts where in the cart or protruding screws, making the cart bottom heavy so tipping of the cart will be avoided, and assuring cart is capable of withstanding the provided amount of weight.

Maneuverability of the cart worked great. The locking caster wheels in the back of the cart provided controlled "shopping cart" like steering to the concessions cart. when the locks were disengaged, the cart moved freely and could easily be moved in all directions. Locking the caster wheels in a forward direction is recommended when transporting the cart more than a few feet

The final appearance of the cart reflects Zane Middle School's colors and our client's recommendation.

Maintenance

Maintenance on the Falconstein concessions cart is relatively low, only costing about $7.50 per year. This amount is to cover the cost of oiling the caster wheels and occasional paint chipping. This cart is recommenced to be stored indoors to avoid any long term damage to the material (wood/metal) due to rain and ice.

Schedule

- Yearly

- The friction points in the caster wheels will need to be oiled once every year (or whenever necessary). Spraying some WD-40 in the rotating areas of the wheels will help lubricate the the wheels and prevent damage.

- It is recommended that the cart be inspected for paint chipping, or damage every year. Paint minimizes the damage to the exterior of the cart.

Instructions

The use and setup of this cart will have a few easy steps, it was designed to be compact when moving and to expand and create more surface area when set up.

Locking Casters

This cart has four full swivel caster wheels which gives the cart the ability to move in any direction with very little effort from the user. Simply pushing the cart in any direction will cause it to move. The back two wheels of the cart can turn from full swivel to directional locking casters. This is so the cart is easier to move when being transported, giving it maneuverability similar to a shopping cart where the front wheels are free to move in any direction but the back wheels are fixed in a forward direction.

The levers in the two back wheels are yellow to prevent any confusion between the back directional locks and the non painted front brakes (using your foot is most common to apply the the locks))

Brakes

The brakes are designed to keep the cart from moving. This can be accomplished in a very similar way to how the back wheels of the cart are directionally locked.

Slide Out Table

The cart contains a slide out shelf on the right side (when facing the front of the cart). This is made to give the cart more surface area when stationed, allowing for more items to be placed on top of the cart.

Troubleshooting

| Problem | Suggestion |

|---|---|

| Cart is stuck in position and will not move | Make sure brakes (non-painted levers on the left side of the cart when facing it) are in the upmost position. |

| Wheels will not lock in a forward position | Make sure to push the cart forward at least two feet before applying the directional locks. This will insure both wheels are facing in one direction. |

| Slide out shelve is stuck | Lift the slide out shelve from its usual resting area ( this will only be a few centimeters), then push and pull the slide out a few inches in both direction (inside and out). Place the slide out back down. check to make sure slide out table is working properly. |

Discussion and next steps

The Falconstein Cart is a sturdy structure capable of being packed full of drinks and snacks, and transporting them without trouble. It is a spacious cart that will last many years with proper maintenance. Team The Best Designers are proud with the results of this cart and happy to serve the community. The Next Steps are to collect feed back on the long and short term use of this cart. By doing this we can gather information on what worked really well and what can be improved for future designs.

Suggestions for future changes

We found the final structure of our design to be a bit too wide, when designing 2.5feet of width id not seem like much, but the cart ended with a lot of inside room, almost creating more work then is needed when reaching for the goods inside. It is recommended not to exceed 2 feet in width.

Following the maintenance directions will ensure a long lifespan of the Falconstein cart. Replacing screws that will rust if exposed to constant rain will help further the time the Faclonstein cart is functional.

References

- https://www.eurekacityschools.org/index.php?option=com_content&view=article&id=50&Itemid=141

- HowStuffWorks.com.<https://science.howstuffworks.com/life/genetic/question598.htm> 27 February 2019

- Sudiyani, Y., Tsujiyama, S.-I., Imamura, Y., Takahashi, M., Minato, K., and Kajita, H. (1999). “Chemical characteristics of surfaces of hardwood and softwood deteriorated by weathering.” Journal of Wood Science, 45(4), 348–353.