| Line 20: | Line 20: | ||

'''Description of Solution''' | '''Description of Solution''' | ||

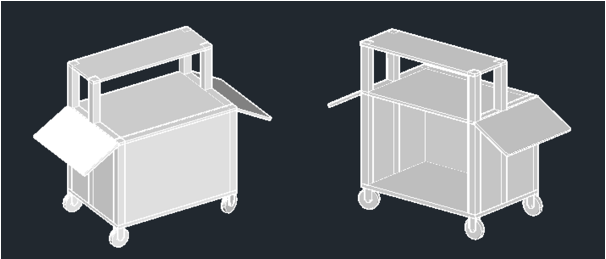

The following describes each aspect of the cart in detail. Figure 5-1 below is an autocad depiction of our final solution. | The following describes each aspect of the cart in detail. Figure 5-1 below is an autocad depiction of our final solution. | ||

[[File:CCC_autocad_drawing.png]] | |||

Figure 4-1: AutoCAD of final design. (Drawn by Kainalu Asam) | Figure 4-1: AutoCAD of final design. (Drawn by Kainalu Asam) | ||

| Line 26: | Line 28: | ||

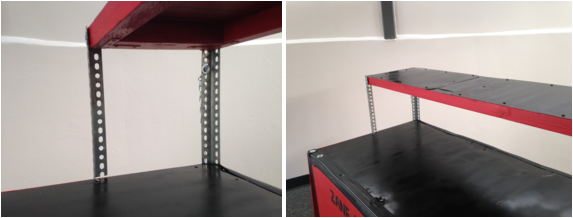

The shelves we reclaimed from the scrapyard are made of old road signs. The larger sign used for the bottom shelf was roughly three feet by two feet. The two signs used for the top shelf are each one foot by one and a half feet. They are connected via the slotted angle posts with screws and washers and supported by a two inch by two inch wooden frame. Figure 4-2 and 4-3 below illustrate the posts and shelves used in the final design. | The shelves we reclaimed from the scrapyard are made of old road signs. The larger sign used for the bottom shelf was roughly three feet by two feet. The two signs used for the top shelf are each one foot by one and a half feet. They are connected via the slotted angle posts with screws and washers and supported by a two inch by two inch wooden frame. Figure 4-2 and 4-3 below illustrate the posts and shelves used in the final design. | ||

[[File:CCC_Post_shelf_material.png ]] | |||

Figure 4-2 (left) and Figure 4-3 (right): Images of slotted angle frame post and road sign shelves with a two by two inch wooden frame. | Figure 4-2 (left) and Figure 4-3 (right): Images of slotted angle frame post and road sign shelves with a two by two inch wooden frame. | ||

| Line 31: | Line 34: | ||

'''Extendable Shelves''' | '''Extendable Shelves''' | ||

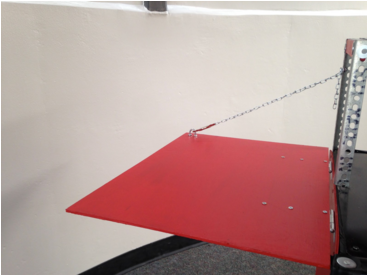

The extendable shelves are constructed of a thin sheet of plywood attached using a double sided hook and U-Bolt with a non-locking hinge to the bottom shelf and a hanging chain connected to the top shelf; this will be detached during transit. Figure 4-4 below shows the extendable shelf mechanism. | The extendable shelves are constructed of a thin sheet of plywood attached using a double sided hook and U-Bolt with a non-locking hinge to the bottom shelf and a hanging chain connected to the top shelf; this will be detached during transit. Figure 4-4 below shows the extendable shelf mechanism. | ||

[[File:CCC_folding_shelf.png]] | |||

Figure 4-4: Extendable shelf of final design. | Figure 4-4: Extendable shelf of final design. | ||

| Line 37: | Line 42: | ||

The storage area will provide a space for the merchandise from the extendable shelves when in transit. It will be enclosed with a thin sheet of plywood on three sides. Figure 4-5 shows the base is made of wire racks and a sheet of plywood. | The storage area will provide a space for the merchandise from the extendable shelves when in transit. It will be enclosed with a thin sheet of plywood on three sides. Figure 4-5 shows the base is made of wire racks and a sheet of plywood. | ||

[[File:CCC_storage_area.png ]] | |||

Figure 4-5: Base storage area of concession cart. | Figure 4-5: Base storage area of concession cart. | ||

| Line 75: | Line 81: | ||

{{How to | |||

|title=Concession Cart Construction | |||

|size= 180 | |||

|Image:CCC_Post_shelf_material.png|Level out bottom. (Photo by Hanna Phillips) | |||

|1|'''Posts/Shelf Material''' | |||

The shelves we reclaimed from the scrapyard are made of old road signs. The larger sign used for the bottom shelf was roughly three feet by two feet. The two signs used for the top shelf are each one foot by one and a half feet. They are connected via the slotted angle posts with screws and washers and supported by a two inch by two inch wooden frame. Figure 4-2 and 4-3 below illustrate the posts and shelves used in the final design. | |||

|Image:Sanding1.jpg|Mechanical sanding (Photo by Oliver Rogers) | |||

|2|Sand down the driftwood with a electric sander to remove most of the larger imperfections. | |||

|Image:Sanding2.jpg|Sanding by hand with finer grit sandpaper(Photo by Oliver Rogers) | |||

|3|Using 150 grit sandpaper, sand down more of the minor imperfections in the wood to get it as smooth as possible. | |||

|Image:Stainingdriftwood.jpg|Staining the wood (Photo by Oliver Rogers) | |||

|4|Apply stain to the driftwood, carefully following manufacturer's directions. | |||

|Image:Fotddriftwood1.jpg|Drilling mounting holes (photo by Oliver Rogers) | |||

|5|Using an electric drill with a 1/2 inch drill bit, drill a hole in the bottom of the driftwood to mount the support post to the base. Using a level, drill another hole at the top to mount the wheel. | |||

|}} | |||

Include a how to use and maintain section. See the how to template below. | Include a how to use and maintain section. See the how to template below. | ||

Revision as of 04:48, 29 April 2016

Abstract

The Smart Cart design project's result is the implementation of a new and improved concession cart for Bernie Levy of Zane middle school. The cart will allow him to more efficiently transport goods and snacks from the cart's storage and loading zone to the outdoor area where kids will purchase such goods. Pending.

One paragraph summary of your project from background to discussion and next steps.

There should be an image near the top.

Background

Bernie Levy at Zane Middle School in Eureka has employed our project design project group, The Concession Cart Crew, to solve an issue within the concession cart system that the school currently uses to sell snacks during their daily break. He presented criteria that he expects us to implement into the design of a new concession cart. His main goal is for it to be a dependable and efficient way to transport snacks and goods across the school campus.

Problem statement and criteria

Our clients biggest concern for the new cart is the noise level that it will make when being pushed across the campus and past classrooms. Other criteria that our client is concerned about is: handles for easy transportation, the weight of the carts being too heavy for students to push, the strength of the shelves on the cart not being able to withstand the weight of the supplies being sold, reducing the four carts they have now into one or two, creating lips around the shelves so that objects will not fall off, creating cushions on the perimeter of the cart to prevent damaging doorways, and creating a cover for when the carts are being stored.

Description of final project

Here is a full description of the final design decision and process for the concession cart. It will also include the qualitative and quantitative costs in addition to tables representing those values. Installment, use, and maintenance recommendations will be described, followed by the final results through the testing process.

Description of Solution The following describes each aspect of the cart in detail. Figure 5-1 below is an autocad depiction of our final solution.

Figure 4-1: AutoCAD of final design. (Drawn by Kainalu Asam)

Posts/Shelf Material The shelves we reclaimed from the scrapyard are made of old road signs. The larger sign used for the bottom shelf was roughly three feet by two feet. The two signs used for the top shelf are each one foot by one and a half feet. They are connected via the slotted angle posts with screws and washers and supported by a two inch by two inch wooden frame. Figure 4-2 and 4-3 below illustrate the posts and shelves used in the final design.

Figure 4-2 (left) and Figure 4-3 (right): Images of slotted angle frame post and road sign shelves with a two by two inch wooden frame.

Extendable Shelves The extendable shelves are constructed of a thin sheet of plywood attached using a double sided hook and U-Bolt with a non-locking hinge to the bottom shelf and a hanging chain connected to the top shelf; this will be detached during transit. Figure 4-4 below shows the extendable shelf mechanism.

Figure 4-4: Extendable shelf of final design.

Storage Area The storage area will provide a space for the merchandise from the extendable shelves when in transit. It will be enclosed with a thin sheet of plywood on three sides. Figure 4-5 shows the base is made of wire racks and a sheet of plywood.

Figure 4-5: Base storage area of concession cart.

Wheels The wheels are five inch polyurethane casters. The front two are swivel and the back are non-swivel. This allows easy turning and stable steering when needed. The polyurethane material they are made out of will prevent the noise our client currently has an issue with. Figure 4-6 and 4-7 show the difference between swivel and fixed casters.

Figure 4-6 (left) and Figure 4-7 (right): Five inch fixed and swivel casters.

Cover The cover is made out of a reclaimed bedsheet from a thrift store. Its purpose is to hide the merchandise from the children's view in order to prevent the urge to steal the snacks. The cover will be resized to fit snug around the cart. Figure 4-8 below shows how the cover fits on the cart.

Figure 4-8: Bedsheet cover for cart.

Rubber Bumper The rubber bumpers are made from upcycled bicycle tires that were reclaimed from a local bicycle shop. They will provide extra protection for the edges and corners of our cart to prevent damages made to the cart itself and to doorways when in transit. Figure 4-9 and 4-10 show how the rubber bumpers are attached around the cart.

Figure 4-9 (left) and Figure 4-10 (right): Rubber padding around the cart.

Handles The handles are from two plastering trowels that have been detached from the metal sheet. The plastic handle remaining is then bolted to the metal post frame between the top and bottom shelf. Figure 4-11 below shows how the handles are attached to the frame.

Figure 4-11: Handles for pushing.

Costs The following section describes the qualitative and quantitative costs of the construction of the concession cart.

Design Cost (hours) We have worked at total of 296 hours on this design project for Zane Middle School. The pie chart, Table 4-1, illustrates the division of hours for each phase of the project.

Table 4-1: Table below divides the number of hours spent during the project into each phase.

Implementation Cost ($) Table 4-2 indicates the cost of materials that have been purchased for the implementation of the cart. A total of $263.39 has been spent on materials which is below the projected budget of $325.00.

Include a how to use and maintain section. See the how to template below.

Costs

| Quantity | Material | Source | Cost ($) | Total ($) |

|---|---|---|---|---|

| 1 | Road sign shelf (3'x2') | Arcata Scrapyard | 5.45 | 5.45 |

| 4 | Road sign shelf (1.5'x2') | Scrapyard | 2.76 | 10.90 |

| 1 | Wire rack | Scrapyard | .50 | .50 |

| 1 | Plywood (2'x4'x1/4") | Ace | 17.55 | 17.55 |

| 25 | Fender washers (1/4)" | Mill Yard | by lb | 1.00 |

| 2 | Hinges | Ace | 6.00 | 6.00 |

| 1 | Lumber (2"x4") | Mill Yard | 4.76 | 4.76 |

| 1 | Lumber (2"x2") | Mill Yard | 5.60 | 5.60 |

| 1 | Slot Angle Post (1.25"x1.25") | Ace | 35.00 | 35.00 |

| 100 | Screws | Mill Yard | 4.18 | 4.18 |

| 3 | Tire Inner tubes | Revolution Bicycle Repair | 0.00 | Donated |

| 1 | Bedsheet | Arcata Hospice | 4.00 | 4.00 |

| Total Cost | $96.39 | |||

Use Help:Table_examples#Cost_Table.

Testing Results

Upon completing the carts construction, we came across a few unforeseen errors. These technical faults included: an ungrounded wheel; paint that wasn't willing to dry; sharp, protruding corners; and overly lengthy screws that kept the carts extendable shelves from collapsing completely. To solve the problem regarding the uneven wheel, a quarter inch wooden square was implanted above the problem wheel which let it contact the ground, thus allowing the cart to roll at maximum efficiency. What we originally thought was regular black paint turned out to be an oil based paint that still wasn't dry a couple days after its application. The solution that we've decided on is to dab up remaining oil paint with cotton balls and then re apply a coat of normal, dry-able paint. As for the sharp corners, we've sanded them a rounder, smoother edge to maximize safety. The most appropriate solution for the extra screw length is to sand down their ends to allow the shelf to fold down parallel to the carts walls.

How to build

Use Template:How_to

Pending

Discussion and next steps

Pending

References

BBQ Smoker Mods. (2016). “The Smoke Shelf, 22 x 8.5 x 4.5" Upper Rack Grill Expander.” <http://www.bbqsmokermods.com/product-p/gmg-6005.htm> (Feb. 20, 2016).

Beakley, G. C., and Chilton, E. G. (1974). Design: Serving the Needs of Man. Macmillan, New York.

Blake, M. (2014). “McDonald's Is Building a San Francisco Tech Hub.” The Wire <http://www.thewire.com/technology/2014/06/mcdonalds-is-building-a-san-francisco -tech-hub/372847/> (Feb. 20, 2016).

Darcor and Ergoweb. (2001). The Ergonomics of Manual Material Handling. Darcor Limited, Toronto, Ontario.

Display Technologies, LLC. (2015) “Product: Under shelf wire rack.” Innovative Merchandising Solutions, <http://www.display-technologies.com/products/wire-roller-rack> (Feb. 20, 2016).

Ebe, K., and Sekino, N. (2014). “Surface deterioration of wood plastic composites under outdoor exposure.” Journal of Wood Science J Wood Sci, 61(2), 143–150.

FDA. (2015). “Preventing Contamination from the Premises. <http://www.fda.gov/Food/GuidanceRegulation/RetailFoodProtection/FoodCode/uc m186451.htm> (Feb. 20, 2016).

Hankett, J. M. (2016). “Low-Volatility Model Demonstrates Humidity Affects Environmental Toxin Deposition on Plastics at a Molecular Level.” Environmental science and technology, 50(3), 130412. (2016).

“S Parker 8in. Folding Shelf Bracket - PAIR (Gray).” The Hardware Hut, <https://www.thehardwarehut.com/catalog-product.php?p_ref=17979#productoption2> (Mar. 9, 2016).

Haygreen, J. G., and Bowyer, J. L. (1989). Forest Products and Wood Science: An Introduction, 2nd Ed., Ames, Iowa.

Keller, T. (2013). “The Psychology Behind a Grocery Store's Layout.” Notre Dame College Online, Notre Dame College, <http://online.notredamecollege.edu/psychology/the -psychology-behind-a grocery-store’s-layout/> (Feb. 23, 2016).

Kim, G.-H., Lee, J.-W., and Seo, T.-I. (2013). “Durability Characteristics Analysis of Plastic Worm Wheel with Glass Fiber Reinforced Polyamide.” Materials, 6(5), 1873–1890.

Manufacturer Express, Inc.,. “3/8 in. 14 ft. Binder Chain Transport Grade 70 Clevis Slip “https://Www.Mfrexpress.Com/Images/Large/Cargocontrol/Binder_Chain_With_Cle vis_Slip_Hook_LRG.Jpg. 2016. Web. 24 Feb. 2016. (2016). “Quantum Storage Blue Wire Shelving Cover with Zipper Closure.” MSC Industrial Supply Company, <http://www.mscdirect.com/product/details/61749552> (Mar. 10, 2016).

Oxford University Press. (2016). “Definition of planogram in English:” Oxford Dictionaries, Oxford University Press, <http://www.oxforddictionaries.com/definition/english/planogram> (Feb. 23, 2016).

Phillips, J. L. (1998). The bends: compressed air in the history of science, diving, and engineering. Yale University Press, New Haven, CT.

SDS London. Cabin Hook Loose Pattern 152Mm. 2016. Web. 24 Feb. 2016.

Terwogt, M. M., and Hoeksma, J. B. (1995). “Colors and Emotions: Preferences and Combinations.” The Journal of General Psychology, 122(1), 5–17.

See Help:Footnotes for more. Template:Reflist