Abstract

The purpose of this project was to work with Zane Middle School representative and P.E. Instructor, Garett Montana, to address the problems of storing and transporting P.E. equipment. The need for a P.E. equipment cart for the school was addressed and different designs were analyzed for possible solutions. The most important design of the cart must allow for storage of the P.E. jump-ropes that prevents them from tangling and kinking.

Background

Zane Middle School, located in Eureka, CA is one of the largest middle schools from just north of San Francisco all the way up to Oregon. P.E. is a mandatory class for all students who attend the middle school; there are 6 P.E. classes a day (each 1 hour long) 5 days a week. At the start of every P.E. class they begin by doing jump-roping, and they continue to do so until the last person has finished, after which they then begin their daily activity. Zane Middle School reached out to our class because the P.E. class is in need of a cart which needs to accomplish a few things; easily transport and store P.E. equipment while also preventing tangling/ kinking of the jump-ropes.

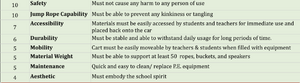

Problem Statement and Criteria

Zane Middle School's P.E. classes have to manually move all of the P.E. equipment separately every class and have to manually return each separately as well. When returning jump-ropes after use students roll each up and they are all thrown into a bucket for storage. This system for storing jump-ropes results in tangling and kinking of the jump-ropes, leading to longer time to unravel them and having to used kinked jump-ropes which makes them harder to use. To solve this Problem Team Enterprise has designed and created a cart that would allow for all equipment to be stored and moved all together on one cart; in doing so it also secures and properly stores jump-ropes preventing them from tangling and kinking.

Description of final project

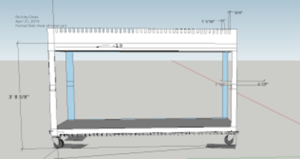

The P.E. Equipment cart is approximately four feet tall and features lower shelving for bucket storage as well as room for other supplies as needs. A top shelf is also included allowing for additional storage and simple access to supplies. The cart’s special design is an original Team Enterprise design; around the top sides of the cart are boards on both sides which securely hold the jump ropes. These boards are made from wood and were individual cut out in a tooth like design. It stores jump ropes in the crevasses in between each “tooth”and are held in place by inverted hooks at the bottom side edges of the cart. One simply folds the jump rope in half and hooks the rope below, then holding both handles notch them in the slot above corresponding to the right hook. This design enables the jump ropes to be held and stored without tangling and preventing kinking, allowing for the jump ropes to be in better shape when using and last longer. The cart is simple yet meets all the qualifications from the client.

Prototyping

Costs

| Quantity | Material | Source | Cost ($) | Total ($) |

|---|---|---|---|---|

| 1 | 10ft x 1ft x 2” piece of Pine Wood | The Mill Yard | 40.00 | Donated |

| 1 | Polypropylene Cart | Harbor Freight | 130.00 | Donated |

| 2 | Screws/bolts sets | Ace Hardware | 20.00 | 20.00 |

| 1 | Hooks Set | Ace Hardware | 14.95 | 14.95 |

| 6 | Cans of Spray Paint | Ace Hardware | 40.00 | 40.00 |

| Total Cost | $74.95 | |||

Testing Results

How to build

|1| Get (1) piece of wood approximately 10ft x 1ft x 2”

|2| Putting it together

|3|

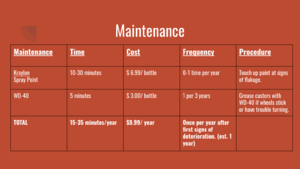

Maintenance

This P.E. equipment cart requires very minimal maintenance and very rarely.

Schedule

This is when to maintain what.

- Daily

- No daily tasks

- Weekly

- No weekly tasks

- Monthly

- No monthly tasks

- Yearly

- Grease casters if cart no longer moves as smoothly (done most easily with WD-40)

- Every 2-3 years

- Repaint Cart

Instructions

This is how to maintain. The step by step how to template {{How to}} is most likely best for this part.

Troubleshooting

This is only how to troubleshoot basic operation. For complex issues, contact Team Enterprise at Humboldt State University.

| Problem | Suggestion |

|---|---|

| Wheels not moving smoothly | Grease caster wheels (done most easily with WD-40) |

| Paint Peeling or Fading | Repaint with appropriate colored Kraylon spray paint |

Discussion and next steps

Suggestions for future changes

Caster wheels can be replaced by simply unscrewing with a phillips-head screwdriver or drill.

References

Contact details

Add your contact information.