Mechanical Engineering Graduate student from Michigan Technological University. I like to learn new things everyday. Hobbies include trying out new cooking recipes, reading books on world politics and finance, sketching portraits, singing, watching TEDTalks.

I recently graduated with a Master's degree in Mechanical Engineering and currently work as a volunteer on projects involving CAD for additive manufacturing. You can view my resume from the link attached below (It should open).

Last year, I got the opportunity to work with Whirlpool Corporation in Amana, IA as a Manufacturing Engineer with the Quality Control Dept. I assisted a Senior Quality Engineer with a few capital saving projects within a cross-functional team. The experience with the home appliance manufacturer was great and during a 2 week shutdown, I took advantage of the time off to get certified as a Lean Six Sigma Green Belt from Coursera. This really helped me while I was midway in this internship.

Before coming to the States, I've also been a Quality Engineering Intern at Indian Railways in 2018 where I explored the diesel locomotives at the Diesel Loco Shed, Pune, India. I got the opportunity of studying the engine failure reports and after drawing Pareto charts and fishbone diagrams, I suggested changes to the design of the engine head to mitigate the overheating issue in 70% of the cases.

I got another interesting opportunity to work at my uncle's workshop in summers of 2016 & 2017. This workshop had a CNC Router machine which was used to make decorative designs on MDF and acryclic sheets for architects and other clients. Making designs in AutoCAD or CoralDRAW, programming a 3-axes machine in MasterCAM for tool path generation, negotiating with customers, etc. were some of the skills I got from this internship.

I was a member of the Student Formula SAE Enterprise - Team VAMOS Autocross - for 3 years during my Bachelor's where I worked at different positions on the design team. My primary role was to design and manufacture the chassis and the bodyworks while also managing the car ergonomics. I first of all tried to lower the Center of Gravity by placing the engine a bit lower than what had been tried before. I was successful in bringing down the chassis weight to 23 kgs during my time at VAMOS by changing the tubing material from AISI 1018 to 4130 Chromoly Steel which maintained the rigidity for reduced weight. This helped in eliminating some frame members and thus helped make the space frame lighter. I also got the chance to represent my university as well as my country in an FSAE event in Japan. Here, I got to interact with many international students and some of the best FSAE teams. Over the 3 year journey, the team had managed to get awarded in CAE & Acceleration events.

Please fee free to reach me at srjain@mtu.edu

Past Work Relevant to Appropedia

Here is something I learnt in the 3D printing class in Fall 2019 at Michigan Tech. I'm glad I've become a member of the open-source community through this class.

Open Source 3-D Printing Class

My Mini Projects

-

A picture of my operational 3-D printer

-

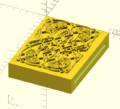

3D Printing Failure Database example (make sure to email documents to Alex - at least 1 but can submit more than 1 for additional chances at filament)