Michael Holt (Open Source Hardware Enterprise)

Working with OSHE

I am a senior Electrical Engineer at Michigan Technological University. Spring 2015 is when I became a member of the OSHE team. In the beginning of the spring semester the team had a few projects that needed to be completed. Those designs ranged from an Prusa i3 and Gigabot 3-D printers, a Lasersaur laser cutter/etcher and an induction furnace. Although I started off spending a little bit of time on different projects I ended up teaming up with Nicholas Kasza to complete the Prusa i3.

Prusa i3

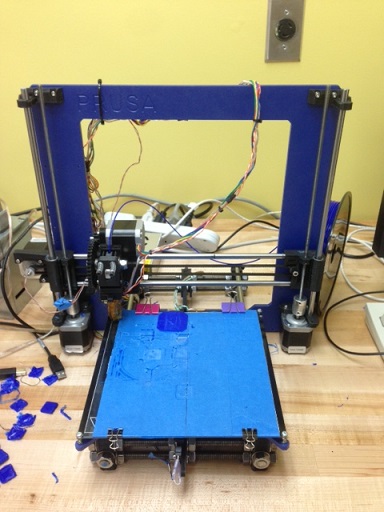

Fig. 1: Prusa i3 3-D Printer. Developed by Prusajr

The Prusa i3 printer is the newest 3-D printer design from RepRap. This design has stronger frame rigidity and easier assembly then their older models. The OSHE team and I would like to use this printer to help not only our group with future projects, but mostly to enhance the productivity of other MTU students. The Prusa i3 will allow different enterprises, senior design teams and other students to obtain customized parts and tools at a lower cost and agile time.

Constructing the Prusa i3

At the beginning of this semester The frame of the Prusa i3 was completed. There were still a few other tasks that had to be finished before we could start any troubleshooting. The extruder, single-frame bed, wiring and configuring the micro-controller were left to be done.

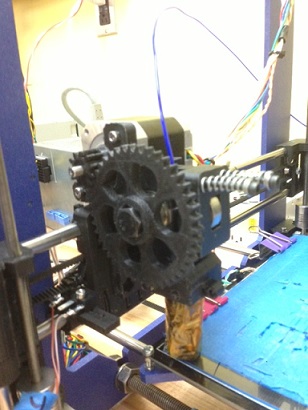

Fig. 2: Prusa i3 Extruder

The first part to be assembled was the extruder which is shown in the picture above. The extruder is one of the main components of almost every 3-D printer. Its motor feeds the filament to the thermistor for heating. Most of the parts were 3-D printed on one of the team's older printers. This really cut down the overall cost of the newer printer.

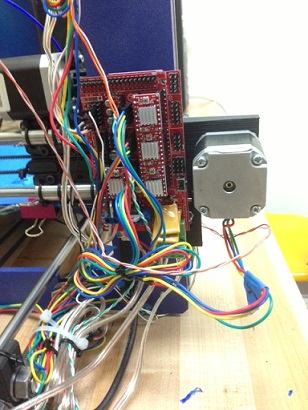

Fig. 3: Arduino Board

The Arduino board acts as the brain of the Prusa i3. It controls all of the moving parts of the printer. The main task that had to be completed here was the connection of the x,y and z motors, sensors, power and USB in order to talk to the computer. With the help from other OSHE team members we were able to solder and connect all of the wires to and from the Arduino board.

Final Actions

After all of the parts were connected and the firmware was added to the Arduino board we were able to connect the printer to the computer and start troubleshooting(the longest part of design). To help with the troubleshooting we used Cura and Pronterface software. Cura is used to edit/cut the model that is going to be 3-D printed and Pronterface gives the user full functionality of the Prusa printer. Nick and I have now been troubleshooting the printer for 2 weeks and it is now printing! There are still a few small things that need to be done in order to get the print to look flawless. We hope to finish these tasks in the next couple of days and leave this semester with a fully functional Prusa i3.