About Me

- Landon Overesch

- I am an 3rd year Environmental Engineering Student at Michigan Technological University. I play Soccer, run and snowboard. I really enjoy the outdoors, generally hunting, fishing, hiking, and rock climbing. I am part of the Open Source Hardware Enterprise (OSHE). More Specifically, I am part of the filament extruder team.

Interests

- Ecology

- Green processes/technologies

- Waste reuse

Projects

Year 3, Fall 2017:

As part of the filament extruder team, I am working with 3D printing filaments and the process of making them. This semester I have taken on the project of researching the processes of refining waste materials (wood, glass, etc.) which could then be infused into 3D printing filaments. This project also includes initial research into the testing of these filaments (primarily wood infused) to get a better understanding of their new properties, such as strength, decomposition, and their environmental impact. Along with the reuse of waste materials in 3D printing filament, I have also begun research on HIPS filaments and its potential for reuse after being dissolved in different solvents. I plan to conclude research and begin testing this next semester upon the completion of the filament extruder.

I have also started looking into different ways to reduce plastic waste from the 3D printing we do in our lab. With the goal of being a waste free enterprise in mind.

I also assisted in the production of the Husky statue order.

Year 3, Spring 2018:

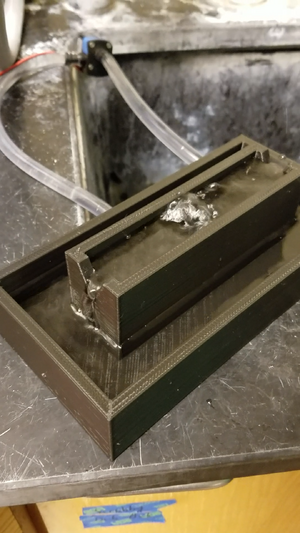

As part of the filament extruder team, my main focus deviated from from last semesters. I focused mainly on the redesign of the filament water cooler. Taking elements from the previous design and implementing new ones, a new water cooler was modeled and 3D printed. The new design includes a larger open top basin surrounding the filament running tower, redesigned inflow and outflow channels, customizable inlet and outlet ports, a raised bottom height in the filament running tower, a closed loop pump system, and triangular (V-type) notches on either side of the filaments running towers. The triangular notches on either side of the tower act as weirs controlling the flow of the water in the system, while, simultaneously providing a raised water surface allowing for complete submersion of the filament. Triangular weirs were chosen over other designs because they typically produce a higher critical height. The filament will then have a higher water level to pass through, making sure the filament will be fully cooled. Alterations are still being made, such as water proofing and flow control. Containment is the primary focus once the water cooler is completed. This is critical to the overall filament extruder as many electrical components are exposed in a relatively small area. Making sure no water leakage occurs is an extremely important part of this project.

Experience

Previous work:

- Managing industrial waste and waste products.

- Beneficial reuse of waste materials .