| Line 14: | Line 14: | ||

== OSHE Work (Spring 2016) == | == OSHE Work (Spring 2016) == | ||

: This semester I worked exclusively on the Lasersaur, and I'm proud to say it is now fully functional. | : This semester I worked exclusively on the Lasersaur with Tate Hanawalt, and I'm proud to say it is now fully functional. | ||

: Working with Tate Hanawalt, we realigned all the mirrors to reflect the full laser. | : Working with Tate Hanawalt, we realigned all the mirrors to reflect the full laser. | ||

: After the machine was fully mechanically adjusted we set to work on the software for the machine. It is currently controlled by a Smoothieboard, running the laser cutter version of the firmware. There are three main ways to generate gcode for use with the Lasersaur: J Tech Photonics Tool, 305 Engineering Raster, and Graycoder. The first two are extensions for Inkscape and open-source which we modified slightly to work with our hardware. The third, Graycoder, is a standalone Java application I created to create gcode that engraves grayscale images in wood and other materials. | : After the machine was fully mechanically adjusted we set to work on the software for the machine. It is currently controlled by a Smoothieboard, running the laser cutter version of the firmware. There are three main ways to generate gcode for use with the Lasersaur: J Tech Photonics Tool, 305 Engineering Raster, and Graycoder. The first two are extensions for Inkscape and open-source which we modified slightly to work with our hardware. The third, Graycoder, is a standalone Java application I created to create gcode that engraves grayscale images in wood and other materials. | ||

Revision as of 04:00, 28 April 2016

About Me

- My name is Ian Peoples, I'm a fourth-year Computer Science student at Michigan Technological University. I've been involved in the Open Source Hardware Enterprise for three years.

OSHE Work (Spring 2015)

- This semester I worked on the Prusa i2, the Gigabot as well as providing technical help across the board.

Prusa i2

- Early in the semester, due to a misfire when trying to flash firmware onto another printer, the firmware on the i2 had to be redeployed and recalibrated. Little adjustment was necessary as I had an earlier version of the firmware on hand that I could easily modify to the current state of the machine. I redeployed Sprinter and calibrated all the appropriate values, mainly the steps per unit of each axis and the overall length of each axis. It is now in printing condition, but some print settings may need to be adjusted, and this can be done easily through Cura. No physical adjustments were made.

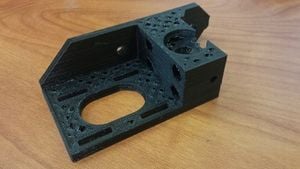

To the right is a recent print from the i2 using the current firmware and print settings. The holes can be fixed by increasing the shell thickness and reducing the print temperature.

Gigabot

- At the beginning of the semester, the Gigabot could move along all its axes (mostly) and had some mechanical errors. This led to it being reworked several times. For example, adjusting the print head in any way would involve re-leveling the print bed. Almost every adjustment we made (and there were many) required more adjustments elsewhere. I can't speak to much of the mechanics of the device, but it uses RAMPS/Arduino combination running Sprinter as the firmware. Sprinter was chosen because I've used it before on the i2 and its relative ease of modification. After adjusting the steps per unit and length of each axis (a significant adjustment because of the relative size) it came down to the final few adjustments to allow printing. Now, finally, after a semester-long refining process, it is in printing condition. However, the print settings need to be adjusted to increase print quality.

OSHE Work (Spring 2016)

- This semester I worked exclusively on the Lasersaur with Tate Hanawalt, and I'm proud to say it is now fully functional.

- Working with Tate Hanawalt, we realigned all the mirrors to reflect the full laser.

- After the machine was fully mechanically adjusted we set to work on the software for the machine. It is currently controlled by a Smoothieboard, running the laser cutter version of the firmware. There are three main ways to generate gcode for use with the Lasersaur: J Tech Photonics Tool, 305 Engineering Raster, and Graycoder. The first two are extensions for Inkscape and open-source which we modified slightly to work with our hardware. The third, Graycoder, is a standalone Java application I created to create gcode that engraves grayscale images in wood and other materials.

- All the code I have written thus far is open-source and available on Github (my username is NuclearEagleFox). The extension modifications are here and Graycoder is available here.

- I'm working on more detailed documentation that describes the inner workings of the code I've written. This is forthcoming.