The open source movement is something that has emerged which supports the open sharing and licensing of software and creative content. The basic idea behind it is "open collaboration" that advances the improvements across open source communities. By exchanging information and having transparency in our development (instead of keeping things secret) we can achieve so much more within those communities. This idea is very attractive to me because the idea of sharing ideas and working off one another to improve them will ultimately lead to a better future for our world. We will be able to advance technologically at a much faster rate than if we stick to the closed formality. However, even though ideas are open and accessible to anyone, anyone that works on an idea should receive credit for their contribution, and plagiarism is something we need to avoid. But I believe this idea of open sourcing holds the key to our future success on this planet.

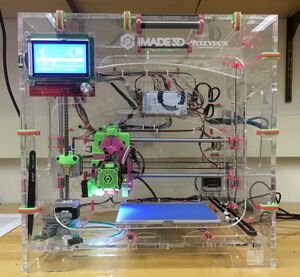

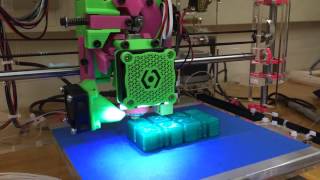

My Jellybox printer is one I put together from the wires up. Without the sharing of knowledge available to me through the open source movement, I would have never been as successful building my printer as I was. Now that it is up and printing, I can search for STL files, edit them, and even create my own to share with the 3D printing community. I hope going forward I can contribute to this open source community and help others the same way it helped me. If I can create new designs or print objects that will benefit someone in the world, I think that would be an empowering experience.

I'm looking forward to see what I learn about 3D printing, the open source community, and myself!

Prints[edit | edit source]

| Picture | Description | Design Source | |

|---|---|---|---|

|

Apple watch charging station | http://www.thingiverse.com/thing:882810 | |

|

Spinning Top- Orbital Series | http://www.thingiverse.com/thing:542914 | |

|

Long Harness Spacer- Jellybox Replacement | https://onedrive.live.com/?authkey=%21AGBDMoy5WsiCigU&id=F56C7E45E370872B%2182715&cid=F56C7E45E370872B | |

|

Vertical Test Coupon | https://osf.io/ur7un/ | |

|

Rock Wall Design Project | Attempted using SketchUp to create a rock wall design from scratch. | |

|

Celtic Salt and Pepper Shaker | https://www.youmagine.com/designs/celtic-salt-and-pepper-shakers | |

|

Test Tube Holder | Designed to hold 16 test tubes that are 15mm in diameter and 90mm high. NIH post contains more details: https://3dprint.nih.gov/discover/3dpx-004890 | |

|

Dust Mask Filter | Designed to cover a request on this page: https://www.appropedia.org/Requests_for_3-D_printable_open_source_appropriate_technology. You can find the file here: File:Dust Mask Complete 1.FCStd |

Videos[edit | edit source]

Projects[edit | edit source]

Mini Mech Project

Introduction: For this lab, we tested how different factors can affect the strength and quality of our 3D prints. For the vertical test coupons, I decided to test different materials: the white filament provided to us, green translucent filament, and metallic gold filament. When I printed these three strips, I kept all the other variables constant. I printed each vertical strip at 50% speed for the coupons to be structurally sound, especially in the thinner middle area. I also printed all three at 210°F, with the coarse 0.3mm layer height, and with 100% flowrate. It will be interesting to see how the color or filament properties affects the strength of the 3D print.

For the horizontal test coupons, I tested how the layer height would affect the strength of the prints. I printed one at each profile in Cura: 0.3m (coarse), 0.2m (medium), and 0.1 (fine). All other variables were constant. I printed all three test coupons with the 3D Solutech PLA gold filament at 100% flow rate and feed rate (speed). I also printed these three coupons at 210°F.

Hypothesis: If I print three vertical test coupons in three different materials, then the white will be the strongest of the three, while the translucent green will be the weakest of the three. This is because the white filament is made of an un-dyed opaque material while the gold and green have color dye which could weaken the filament. The green will be the weakest because the base material that allows it to be translucent is weaker.

If I print three horizontal test coupons with three different layer heights, then the thicker the layer height prints will be stronger than the thinner height prints. This is because, with thinner layers, there is less material extruded on each layer and therefore make weaker connections between one another. In addition, there are more points of potential breakage with the thinner layers Meanwhile, thicker layers have more solid material between each layer and have fewer layers which can lessen the number of potential breakage points.

Analysis: For the vertical test, the white filament ended up being the strongest as I had hoped. The white needed 140N in force before it broke. The gold was the next strongest as I had predicted and needed 115N before it broke. The green was the weakest, however it needed 114N to break. Therefore, the gold metallic and the green translucent filament were nearly identical in their strength. This was something that surprised me! The results of the horizontal tests surprised me a lot. The layer height had the opposite effect on the strength in my experiment. The test coupon with 0.3mm layer height broke with 195N, the 0.2mm coupon broke at 212N, and the 0.1mm coupon broke with 230N. Therefore, the thinnest layer height ended up being the strongest and the thickest was the weakest.

Improvements: If I was to take this experiment further and improve it, I would try to make more variables constant. For example, I would like to use three different colored materials but all from the same company and opened at the same time. This would eliminate variables regarding air and humidity, as well as the manufacturing process and materials. For the horizontal strips, it might be more interesting if I could do a wider range of layer heights such as 0.1, 0.3, and 0.5 instead. I would also like to go each of the vertical and the horizontal at least two more times to eliminate any possible errors that could occur in the testing or printing process. This is especially true for testing the gold and green filament again since they were so close to one another.

Revised Hypothesis: My revised hypothesis for the vertical coupons will be that the white filament is indeed the strongest, but the other two filaments— since they have translucent or metallic properties and not just a regular color dye— are nearly the same strength when tested. This is because the change in base materials significantly affects the strength. My revised hypothesis for the horizontal test coupons is that the thinner layer heights will result in stronger prints, while thicker layer heights will result in weaker prints. This is because the thinner layers will smoosh together more and therefore create a stronger bond between the layers.

Picture gallery[edit | edit source]