About Me

- Hi, I am a PhD student at University of Trento, Italy working as a researcher in the MOST (Michigan tech Open Sustainability Technology) research group at Michigan Technological University researching on integrating FFF 3D printing and Polymer Derived Ceramics.

- I completed my Bachelors in Mechanical Engineering from University of Pune, India in 2016 and completed my Masters in Material Science and Engineering from Michigan Technological University.

Previous Work

- I worked as a research assistant to Dr. Scott Wagner at Michigan Technological University from June 2017 to August 2018 for the project of Accelerated corrosion testing of Aluminum panels for use in automotive applications.

- Before that, I worked as a Design Engineer for a private firm where I designed the heat load and layout of cold rooms for cold storage facilities for goods, food and pharmaceutical companies.

- I also worked as an intern at an Oil seal/ O-ring manufacturing company as a Manufacturing Engineering intern. Where I developed a new time management schedule using lean manufacturing techniques to increase efficiency.

Research

Research Interests

- 3D printing

- Polymers

- Ceramics

- Composite Materials

- Aluminum

- Corrosion

- Material Testing and Characterization

Current Research

3D printing and polymer derived ceramics

Currently I am working on converting FFF 3D printed polymers into ceramics using preceramic polymers.

3D printing of Wood and polymer composites

Working on mixing wood waste from furniture industry and plastic waste and using the composite for 3D priting.

Publications

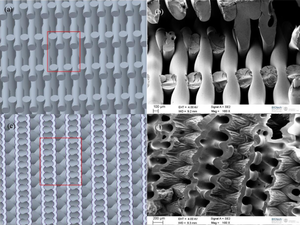

Polymer-derived SiOC Replica of Material Extrusion-based 3-D Printed Plastics

- September 2019 | University of Trento, Italy

The paper explores a new method of obtaining 3D printed ceramics with multilevel porosity. The ceramic structures are manufactured by creating a replica of 3D printed polymers. The 3D printed parts are coated with preceramic polymer called Polysiloxane and then pyrolysed in an inert environment to have porous struts as well as the designed porosity in the structure. These type of ceramics can be manufactured very cheaply compared to traditional ceramic manufacturing processes as well as other ceramic additive manufacturing processes. Additive manufacturing of polymer derived ceramics also gives us freedom of design compared to tradition polymer forming methods such as molding and casting. The ceramics obtained are very stable at higher temperature both mechanically and chemically. These can be used in high temperature applications like heat exchangers, heat sinks and also in chemical applications like catalytic converters.

Additive Manufacturing of Nickel Based Superalloy | Preprint

- May 2018 | Michigan Technological University, USA

This paper reviews the use of relatively new manufacturing method called as additive manufacturing, most often mentioned as 3D printing in fabrication of high performance superalloys. The overview of the article describes the structure, property, processing, performance relationship of the fabrication process and the superalloys. The manufacturing methods such as Electron Beam Melting, Laser Beam Melting and Direct Energy Deposition used to fabricate commercially available alloys are explained. The microstructure / grain structure resulting from directional building, complex thermal cycles is discussed. An overview of the properties of the superalloys and their performance as well as applications is presented.

Diffusion modeling for Dip-pen Nanolithography | Preprint

- May 2018 | Michigan Technological University, USA

The diffusion model for the dip pen nanolithography is similar to spreading an ink drop on a paper. Nanolithography uses Atomic Probe Microscope like probes to deliver the ink drop on to the substrate. The model considers the ink to be molecular. Some models have been developed considering fluid ink, some with thiol inks, particulate inks and polymer inks. The models consider the fluid ink with the added factors such as flow rate, detachment rate, effect due to relative humidity, multilayer flow, the ink drop, with meniscus etc., which makes the model complicated. The aim of this paper is to create a generalized.

Coupled Thermal and Structural Analysis of Brake Disc Rotor Manufactured from Aluminium Metal Matrix Composite (AMMC) reinforced with Silicon Carbide

- June 2016 | University of Pune, India

The research paper focuses on the coupled structural and thermal analysis of the brake disc rotor which is manufactured from a new cutting edge material, Aluminium Metal Matrix Composite reinforced with silicon carbide. The paper discusses the combined effect of thermal and structural loading on the brake disc rotor while in action.

Manufacturing of Disc Brake Rotor Using Aluminium Metal Matrix Composite (AMMC) reinforced with Silicon Carbide

- June 2016 | University of Pune, India

The research paper focuses on the manufacturing of a new improved brake disc rotor from Aluminium Metal Matrix Composite reinforced with Silicon Carbide. The paper discusses the manufacturing methods, the composition and the detail process for the manufacturing of the rotor.

Pages

- 3D printed Polymer Derived Ceramics

- Polymer Derived Ceramics: Process

- Printing 1.75mm filament with Lulzbot Printers

- Tube Furnace Protocol:MOST

Some fun 3D printed stuff

My Hobbies

- Music

I play Indian Classical Flute and a percussion instrument called Tabla. I have been playing Tabla for last 15 years and Flute for last 12 years. I play mostly Indian Classical Music and Hindi film music. Some videos of me playing.

- Cooking

I like to Cook different cuisines but I cook Indian cuisine the best. I like to feed people and see happy faces.

- Gaming

I do some computer gaming and love racing games. I play Assetto Corsa and Project Cars on my racing simulator. Other than that I like FPS and RPG games. Counter Strike and Assassin's Creed are some of my favorites.

- Watch Formula 1 Racing

I am an avid fan of Formula 1 racing and have been following the sport since last 8 years. Being a Mechanical Engineer and knowing the technical stuff makes me even more interested in it. My all tie favorite team is Ferrari and since now I am a student in Italy, my dream is to watch an F1 race at Autodromo Monza. Currently I like Red Bull racing and my favorite drivers are Sebastian Vettel and Max Verstappen.

- Also I am a very tech savvy person and own loads of gadgets. I like automating stuff as much as possible

- Like to watch movies. Fan of Marvel and DC comics.