Sophivorus (talk | contribs) (Normalize) |

|||

| (20 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

[[File:Simon profile.jpg|thumb|Please feel free to [[User talk:6jm23|contact]] me for any concerns questions]] | |||

{{User data | |||

| name = Jianlang Mai | |||

| interests = photovoltaic, service learning | |||

| email = maijianlang@gmail.com | |||

}} | |||

Self-motivated, committed and ambitious Engineering Professional with strong hands-on manufacturing experience, eager to integrate solid work history, fundamental engineering knowledge, and superior problem-solving skill toward securing a Mechanical Engineer (in training) position. | |||

= | == SUMMARY OF STRENGTHS == | ||

''' | '''Engineering Skills''' | ||

* Computational Design/ Analysis Skill: Strong CAD (Solidwork & Solidedge) skill proven in many efficiency-based design projects. Ability to perform numerical analysis using Maple, C++, MatLab and M.S Excel | |||

* Manufacturing Knowledge: Extensive knowledge on manufacturing processes along with production floor hands-on experience and product development experience | |||

* Problem Solving Skill: Strong problem solving skill proven by daily work tasks | |||

''' | '''Communication skills''' | ||

* Information Processing: Effectively research, gather and document technical information for various engineering purposes | |||

* Technical Reports: Comfortable of producing technical documents such as field installation and technical manual with extensive use of Solidwork, Adobe Indesign, Acrobat 3D, MS Word, and PowerPoint | |||

* Technical Presentations: Ability to perform technical presentation efficiently to audiences with various backgrounds | |||

'''Interpersonal skills''' | |||

* Team Player: Manage interpersonal conflicts, motivate others and take charge whenever necessary | |||

* Multi-Tasking: Ability to handle multiple tasks with ability to effectively prioritize | |||

* Self-Motivated: Eager to learn in order to foster personal and professional growth | |||

== | == EDUCATION == | ||

'''Engineering | '''Bachelor of Applied Science, Mechanical Engineering''' | ||

'''Queen's University, Kingston ON Canada''' | |||

'''Related courses''' | |||

* | * Engineering: Engineering Graphics, Manufacturing Methods, Machine Condition and Faults Diagnosis, Internal Combustion Engine, Turbo Machinery, Aerospace Engineering, Material Science Engineering | ||

* | * Physics: Thermodynamics, Heat Transfer, Fluid Dynamics, Compressible Fluid, Statics and Mechanics, Kinematics and Dynamics, Electricity and Magnetism | ||

* | * Mathematics: Calculus, Engineering Data Analysis, Statistic Analysis, Applications Numerical Method | ||

* | * Sustainability Study: Fuel Cell Technology, Engineering Sustainability Development | ||

* Economics: Micro/ Macroeconomics, Engineering Economics | |||

== HONOURS AND AWARDS == | |||

'''The Queen Elizabeth ll Aiming for the Top Scholarship, 2006''' | |||

* Recognizes students who have shown academic excellence | |||

'''Dean's Entrance Scholarship in Applied Science, 2006''' | |||

* Recognizes students entering the Applied Science faculty who have shown academic excellence | |||

== | == WORK EXPERIENCES == | ||

''' | '''CURRENT POSITION''' | ||

''' | [http://www.skyjack.com '''Skyjack Inc., ( Linamar Corp.) Guelph, ON'''] | ||

'''Position:''' Technical Manual Complier '''Date:''' Oct 2010 - Present | |||

* Liaison between engineering design teams, floor production and technical publication department | |||

* Verify engineering change orders, report error and revise technical manuals accordingly | |||

* Document field procedures and generate field installation procedure with use of engineering drawings and CAD software | |||

* Manage the company website data base; ensure the most updated manuals are available to the public. | |||

''' | '''PREVIOUS EXPERIENCES''' | ||

'''Knorr Brake Ltd, Kingston, ON''' | |||

'''Position:''' Mechanical Designer- MECH 460 Client Based Design Project '''Date:''' Sept - Dec 2010 | |||

* To evaluate the feasibility of automating the manifold epoxy coating process, in an effort to relieve the costs of manual labor, as well as to reduce the possibility of error caused by human uncertainty. | |||

* Troubleshot the current process and analyzed the solution, provided detailed CAD modeling, materials selection, dimension/force/pressure analysis, cost analysis and critical analysis. | |||

* Innovative, simple, low maintenance design exceeded the client's expectations. | |||

'''3M Canada, Perth and Brockville ON ''' | |||

'''Position:''' Energy auditor- MECH 425 Engineering Sustainability Development Green IT project '''Date:'''Jan - April 2010 | |||

* Generated an energy conservation measure (ECM) on motion sensing vending machine which calculates the energy reduction, greenhouse gases emission reduction and rate of return of the system. | |||

* | * Based on energy usage patterns and I.T. infrastructure, preformed a feasibility study to the business of implementing numerous technologies, systems, and processes in an effort to reduce the environmental impacts and to improve the economic benefits. | ||

* Found that up to $100,000 can be saved through the energy optimization. | |||

* Gained hands-on energy auditing experiences and insights on energy optimization. | |||

''' | '''Benny's Auto Shop, Toronto, ON''' | ||

'''Position:''' Apprentice '''Date:'''May 2008 -July 2008 | |||

* Took a Nissan 86' Sunny apart to obtain extensive understanding of structure/function of automobile | |||

* Gained hands-on mechanical workshop experience through the utilization of various power tools | |||

* Improved problem shooting and solving skill through basic automobile repairing such as brake replacement, oil/tires changes and body repairing | |||

== | == SCHOOL PROJECTS == | ||

'''MECH 460 Team Design Project with Knorr Brake Ltd, Kingston ''' | |||

* Objective: To evaluate the feasibility of automating the manifold epoxy coating process, in an effort to relieve the costs of manual labor, as well as to reduce the possibility of error caused by human uncertainty. | |||

* Solution: Troubleshot the current process and analyzed the solution, provided detailed CAD modeling, materials selection, dimension/force/pressure analysis, cost analysis and critical analysis. | |||

* Strong points: Innovative, light weight, simple design, low cost, low maintenance | |||

* Goal: Exceeded the client's expectations and was granted to implement the prototype | |||

<gallery> | <gallery> | ||

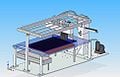

Image:Mainclosed.jpg|Fig 1: Automatic epoxy coating system (closed) | Image:Mainclosed.jpg|Fig 1: Automatic epoxy coating system (closed) | ||

| Line 84: | Line 104: | ||

</gallery> | </gallery> | ||

'''A presentation of some of the CAD drawings from the client based design projects can be seen | '''A brief presentation of some of the CAD drawings from the client based design projects can be seen: [[File:Mai CAD Examples.ppt]]''' | ||

''' | '''MECH460 Green Appropriate Technology project''' | ||

* Objective: To develop a solution to common issues, such as clean drinking water and power issue in developing countries base on ideology of [http://en.wikipedia.org/wiki/Open_source Open Source] and [http://en.wikipedia.org/wiki/Appropriate_technology Appropriate Technology] | |||

* Solution: Water purification system with use of solar energy. | |||

* Strong points: Simple design, low cost, low maintenance and abundant construction materials. The solution can be built and maintained regardless of the location and user skill level. | |||

More information can be found [[Solar water purification system with solar heating|here]] | |||

== ACTIVITIES AND INTERESTS == | |||

'''Sports''' | |||

* Play intramural basketball for 3 years | |||

* Pool table | |||

* Table tennis | |||

*Play intramural basketball for 3 years | * Have free weight strength training 3 times per week for 2 year | ||

*Pool table | |||

*Table tennis | |||

*Have free weight strength training 3 times per week for 2 year | |||

'''Hobbies''' | '''Hobbies''' | ||

* Reading engineering relative materials | |||

* Traveling/ Camping | |||

* Rock climbing | |||

* Playing guitar | |||

[[Category: MECH425-Users]] | [[Category:MECH425-Users]] | ||

Latest revision as of 11:26, 23 September 2021

Self-motivated, committed and ambitious Engineering Professional with strong hands-on manufacturing experience, eager to integrate solid work history, fundamental engineering knowledge, and superior problem-solving skill toward securing a Mechanical Engineer (in training) position.

SUMMARY OF STRENGTHS[edit | edit source]

Engineering Skills

- Computational Design/ Analysis Skill: Strong CAD (Solidwork & Solidedge) skill proven in many efficiency-based design projects. Ability to perform numerical analysis using Maple, C++, MatLab and M.S Excel

- Manufacturing Knowledge: Extensive knowledge on manufacturing processes along with production floor hands-on experience and product development experience

- Problem Solving Skill: Strong problem solving skill proven by daily work tasks

Communication skills

- Information Processing: Effectively research, gather and document technical information for various engineering purposes

- Technical Reports: Comfortable of producing technical documents such as field installation and technical manual with extensive use of Solidwork, Adobe Indesign, Acrobat 3D, MS Word, and PowerPoint

- Technical Presentations: Ability to perform technical presentation efficiently to audiences with various backgrounds

Interpersonal skills

- Team Player: Manage interpersonal conflicts, motivate others and take charge whenever necessary

- Multi-Tasking: Ability to handle multiple tasks with ability to effectively prioritize

- Self-Motivated: Eager to learn in order to foster personal and professional growth

EDUCATION[edit | edit source]

Bachelor of Applied Science, Mechanical Engineering

Queen's University, Kingston ON Canada

Related courses

- Engineering: Engineering Graphics, Manufacturing Methods, Machine Condition and Faults Diagnosis, Internal Combustion Engine, Turbo Machinery, Aerospace Engineering, Material Science Engineering

- Physics: Thermodynamics, Heat Transfer, Fluid Dynamics, Compressible Fluid, Statics and Mechanics, Kinematics and Dynamics, Electricity and Magnetism

- Mathematics: Calculus, Engineering Data Analysis, Statistic Analysis, Applications Numerical Method

- Sustainability Study: Fuel Cell Technology, Engineering Sustainability Development

- Economics: Micro/ Macroeconomics, Engineering Economics

HONOURS AND AWARDS[edit | edit source]

The Queen Elizabeth ll Aiming for the Top Scholarship, 2006

- Recognizes students who have shown academic excellence

Dean's Entrance Scholarship in Applied Science, 2006

- Recognizes students entering the Applied Science faculty who have shown academic excellence

WORK EXPERIENCES[edit | edit source]

CURRENT POSITION

Skyjack Inc., ( Linamar Corp.) Guelph, ON Position: Technical Manual Complier Date: Oct 2010 - Present

- Liaison between engineering design teams, floor production and technical publication department

- Verify engineering change orders, report error and revise technical manuals accordingly

- Document field procedures and generate field installation procedure with use of engineering drawings and CAD software

- Manage the company website data base; ensure the most updated manuals are available to the public.

PREVIOUS EXPERIENCES

Knorr Brake Ltd, Kingston, ON Position: Mechanical Designer- MECH 460 Client Based Design Project Date: Sept - Dec 2010

- To evaluate the feasibility of automating the manifold epoxy coating process, in an effort to relieve the costs of manual labor, as well as to reduce the possibility of error caused by human uncertainty.

- Troubleshot the current process and analyzed the solution, provided detailed CAD modeling, materials selection, dimension/force/pressure analysis, cost analysis and critical analysis.

- Innovative, simple, low maintenance design exceeded the client's expectations.

3M Canada, Perth and Brockville ON Position: Energy auditor- MECH 425 Engineering Sustainability Development Green IT project Date:Jan - April 2010

- Generated an energy conservation measure (ECM) on motion sensing vending machine which calculates the energy reduction, greenhouse gases emission reduction and rate of return of the system.

- Based on energy usage patterns and I.T. infrastructure, preformed a feasibility study to the business of implementing numerous technologies, systems, and processes in an effort to reduce the environmental impacts and to improve the economic benefits.

- Found that up to $100,000 can be saved through the energy optimization.

- Gained hands-on energy auditing experiences and insights on energy optimization.

Benny's Auto Shop, Toronto, ON Position: Apprentice Date:May 2008 -July 2008

- Took a Nissan 86' Sunny apart to obtain extensive understanding of structure/function of automobile

- Gained hands-on mechanical workshop experience through the utilization of various power tools

- Improved problem shooting and solving skill through basic automobile repairing such as brake replacement, oil/tires changes and body repairing

SCHOOL PROJECTS[edit | edit source]

MECH 460 Team Design Project with Knorr Brake Ltd, Kingston

- Objective: To evaluate the feasibility of automating the manifold epoxy coating process, in an effort to relieve the costs of manual labor, as well as to reduce the possibility of error caused by human uncertainty.

- Solution: Troubleshot the current process and analyzed the solution, provided detailed CAD modeling, materials selection, dimension/force/pressure analysis, cost analysis and critical analysis.

- Strong points: Innovative, light weight, simple design, low cost, low maintenance

- Goal: Exceeded the client's expectations and was granted to implement the prototype

-

Fig 1: Automatic epoxy coating system (closed)

-

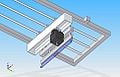

Fig 1a: Automatic epoxy coating system (opened)

-

Fig 1b: Epoxy applicator

A brief presentation of some of the CAD drawings from the client based design projects can be seen: File:Mai CAD Examples.ppt

MECH460 Green Appropriate Technology project

- Objective: To develop a solution to common issues, such as clean drinking water and power issue in developing countries base on ideology of Open Source and Appropriate Technology

- Solution: Water purification system with use of solar energy.

- Strong points: Simple design, low cost, low maintenance and abundant construction materials. The solution can be built and maintained regardless of the location and user skill level.

More information can be found here

ACTIVITIES AND INTERESTS[edit | edit source]

Sports

- Play intramural basketball for 3 years

- Pool table

- Table tennis

- Have free weight strength training 3 times per week for 2 year

Hobbies

- Reading engineering relative materials

- Traveling/ Camping

- Rock climbing

- Playing guitar