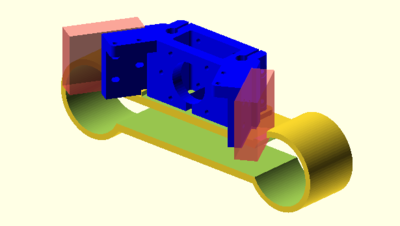

Upgraded Spool Holder

This upgraded spool holder is made to be fully compatible with the current wire holding mount hardware included with the Athena Printer.

Original Author: User:JLaureto

Design and Printing

Design

OpenSCAD was utilized for all modeling operations. The MOST-Athena GitHub file repository is located here. The motor-end assembly was imported into OpenSCAD and the part was designed to accommodate the geometrical constraints of the parts provided to MY4777.

Printing

The stiffness of the component is driven by the infill percentage. Adjust as necessary to achieve your desired characteristics.

- Print Parameters Utilized

- Layer Thickness: 0.2mm

- Skin Thickness: 1.0mm

- Top/Bottom Thickness: 0.5mm

- Temperature: 180C

- Speed: 80mm/s (60mm/s outer contour)

- Flow: 100%

- Infill: 50%

Installation

The model is designed to snap fit onto the bottom of the motors ends. Print out qty. 3 of the STL and install as shown below.

Link to Files

The file repository is located on Thingiverse thing:1809228

Other Sound Dampening Techniques

- The default U,V,W motor acceleration is 4000mm/s. You can uniformly decrease this to any lesser value to quiet the quick movements of the motors / bearings.

- Utilizing a heavy weight grease on the guide rods seems to reduce the vibrations of the quick bearing movements.

See Also

Open Source 3-D Printing Athena Printer Build Overview MORE Delta Mods]