J.M.Pearce (talk | contribs) m (→Source) |

J.M.Pearce (talk | contribs) m (→Source) |

||

| (One intermediate revision by the same user not shown) | |||

| Line 6: | Line 6: | ||

==Source== | ==Source== | ||

* Nuchitprasitchai, S., Roggemann, M. & Pearce, J.M. [http://www.mdpi.com/2504-4494/1/1/2 Three Hundred and Sixty Degree Real-Time Monitoring of 3-D Printing Using Computer Analysis of Two Camera Views]. ''J. Manuf. Mater. Process.'' 2017, 1(1), 2; doi:10.3390/jmmp1010002 [https://www.academia.edu/33773260/Three_Hundred_and_Sixty_Degree_Real-Time_Monitoring_of_3-D_Printing_Using_Computer_Analysis_of_Two_Camera_Views open access] | * Nuchitprasitchai, S., Roggemann, M. & Pearce, J.M. [http://www.mdpi.com/2504-4494/1/1/2 Three Hundred and Sixty Degree Real-Time Monitoring of 3-D Printing Using Computer Analysis of Two Camera Views]. ''J. Manuf. Mater. Process.'' 2017, 1(1), 2; doi:10.3390/jmmp1010002 [https://www.academia.edu/33773260/Three_Hundred_and_Sixty_Degree_Real-Time_Monitoring_of_3-D_Printing_Using_Computer_Analysis_of_Two_Camera_Views open access] | ||

** Open source code : | ** Open source code : https://osf.io/b9h7y/ | ||

** Models : | ** Models : https://osf.io/utp6g/ | ||

[[image:360siranee.jpg |right|700px]] | [[image:360siranee.jpg |right|700px]] | ||

Revision as of 23:27, 6 July 2017

Source

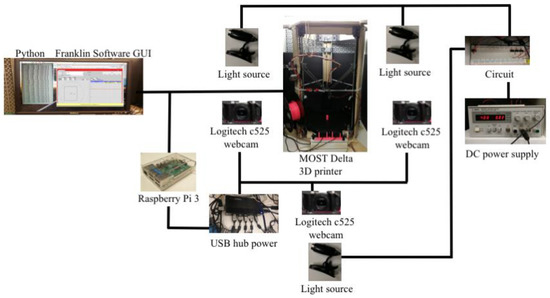

- Nuchitprasitchai, S., Roggemann, M. & Pearce, J.M. Three Hundred and Sixty Degree Real-Time Monitoring of 3-D Printing Using Computer Analysis of Two Camera Views. J. Manuf. Mater. Process. 2017, 1(1), 2; doi:10.3390/jmmp1010002 open access

- Open source code : https://osf.io/b9h7y/

- Models : https://osf.io/utp6g/

Abstract

Prosumer (producing consumer)-based desktop additive manufacturing has been enabled by the recent radical reduction in 3-D printer capital costs created by the open-source release of the self-replicating rapid prototype (RepRap). To continue this success, there have been some efforts to improve reliability, which are either too expensive or lacked automation. A promising method to improve reliability is to use computer vision, although the success rates are still too low for widespread use. To overcome these challenges an open source low-cost reliable real-time optimal monitoring platform for 3-D printing from double cameras is presented here. This error detection system is implemented with low-cost web cameras and covers 360 degrees around the printed object from three different perspectives. The algorithm is developed in Python and run on a Raspberry Pi3 mini-computer to reduce costs. For 3-D printing monitoring in three different perspectives, the systems are tested with four different 3-D object geometries for normal operation and failure modes. This system is tested with two different techniques in the image pre-processing step: SIFT and RANSAC rescale and rectification, and non-rescale and rectification. The error calculations were determined from the horizontal and vertical magnitude methods of 3-D reconstruction images. The non-rescale and rectification technique successfully detects the normal printing and failure state for all models with 100% accuracy, which is better than the single camera set up only. The computation time of the non-rescale and rectification technique is two times faster than the SIFT and RANSAC rescale and rectification technique.

Keywords

Real-time monitoring, 3D printing, Optical monitoring, RepRap, Open hardware, Quality assurance, 2-D reconstruction; error detection; reliability; computer analysis

See Also

- Factors effecting real-time optical monitoring of fused filament 3D printing

- Mechanical Properties of Components Fabricated with Open-Source 3-D Printers Under Realistic Environmental Conditions

- The Effects of PLA Color on Material Properties of 3-D Printed Components

- Viability of Distributed Manufacturing of Bicycle Components with 3-D Printing: CEN Standardized Polylactic Acid Pedal Testing

- Applications of RepRap distributed production - literature review