J.M.Pearce (talk | contribs) m (→See Also) |

J.M.Pearce (talk | contribs) mNo edit summary |

||

| (27 intermediate revisions by 5 users not shown) | |||

| Line 1: | Line 1: | ||

==See | == See also == | ||

* https://patentcenter.uspto.gov/applications/90015140 | |||

| | |||

==== RepRapable Recyclebot and the Wild West of Recycling ==== | |||

{{Grid | |||

| content = | |||

===Recycling Technology=== | {{Video | ||

| video = b04mUaI-oTU | |||

| align = right | |||

}} | |||

{{Video | |||

| video = JxF5gunuM1A | |||

| align = right | |||

}} | |||

}} | |||

=== Recycling Technology === | |||

* [[Recyclebot]] | * [[Recyclebot]] | ||

* [[RepRapable Recyclebot: Open source 3-D printable extruder for converting plastic to 3-D printing filament]] | |||

** [[Improving recyclebot concepts]] | * [[Open Source 3-D Filament Diameter Sensor for Recycling, Winding and Additive Manufacturing Machines]] | ||

* [[Improving recyclebot concepts]] | |||

* [[3-D Printable Polymer Pelletizer Chopper for Fused Granular Fabrication-Based Additive Manufacturing]] | * [[3-D Printable Polymer Pelletizer Chopper for Fused Granular Fabrication-Based Additive Manufacturing]] | ||

* [[Fused Particle Fabrication 3-D Printing: Recycled | * [[Mechanical Properties of Direct Waste Printing of Polylactic Acid with Universal Pellets Extruder: Comparison to Fused Filament Fabrication on Open-Source Desktop Three-Dimensional Printers]] | ||

* [[Fused Particle Fabrication 3-D Printing: Recycled Materials' Optimization and Mechanical Properties]] | |||

* [[Multi-material distributed recycling via material extrusion: recycled high density polyethylene and poly (ethylene terephthalate) mixture]] | |||

* [[Mechanical Properties and Applications of Recycled Polycarbonate Particle Material Extrusion-Based Additive Manufacturing]] | * [[Mechanical Properties and Applications of Recycled Polycarbonate Particle Material Extrusion-Based Additive Manufacturing]] | ||

* [[Wood Furniture Waste-Based Recycled 3-D Printing Filament]] | * [[Wood Furniture Waste-Based Recycled 3-D Printing Filament]] | ||

| Line 19: | Line 34: | ||

* [[Mechanical Properties of Ultraviolet-Assisted Paste Extrusion and Postextrusion Ultraviolet-Curing of Three-Dimensional Printed Biocomposites]] | * [[Mechanical Properties of Ultraviolet-Assisted Paste Extrusion and Postextrusion Ultraviolet-Curing of Three-Dimensional Printed Biocomposites]] | ||

* [[Open Source Waste Plastic Granulator]] | * [[Open Source Waste Plastic Granulator]] | ||

* [[Open-Source Grinding Machine for Compression Screw Manufacturing]] | |||

* [[Sustainability and Feasibility Assessment of Distributed E-Waste Recycling using Additive Manufacturing in a Bi-Continental Context]] | |||

* [[Finding Ideal Parameters for Recycled Material Fused Particle Fabrication-Based 3D Printing Using an Open Source Software Implementation of Particle Swarm Optimization]] | |||

* [[Waste Plastic Direct Extrusion Hangprinter]] | |||

* [[Hangprinter for Large Scale Additive Manufacturing using Fused Particle Fabrication with Recycled Plastic and Continuous Feeding]] | |||

===Distributed Recycling LCA=== | === Distributed Recycling LCA === | ||

* [[Tightening the loop on the circular economy: Coupled distributed recycling and manufacturing with recyclebot and RepRap 3-D printing]] | * [[Tightening the loop on the circular economy: Coupled distributed recycling and manufacturing with recyclebot and RepRap 3-D printing]] | ||

* [[Technical pathways for distributed recycling of polymer composites for distributed manufacturing: Windshield wiper blades]] | |||

* [[Plastic recycling in additive manufacturing: A systematic literature review and opportunities for the circular economy]] | |||

* [[Energy Payback Time of a Solar Photovoltaic Powered Waste Plastic Recyclebot System]] | * [[Energy Payback Time of a Solar Photovoltaic Powered Waste Plastic Recyclebot System]] | ||

* [[Life cycle analysis of distributed recycling of post-consumer high density polyethylene for 3-D printing filament]] | * [[Life cycle analysis of distributed recycling of post-consumer high density polyethylene for 3-D printing filament]] | ||

| Line 31: | Line 53: | ||

* [[Green Fab Lab Applications of Large-Area Waste Polymer-based Additive Manufacturing]] | * [[Green Fab Lab Applications of Large-Area Waste Polymer-based Additive Manufacturing]] | ||

* [[Systems Analysis for PET and Olefin Polymers in a Circular Economy]] | * [[Systems Analysis for PET and Olefin Polymers in a Circular Economy]] | ||

* [[Potential of distributed recycling from hybrid manufacturing of 3-D printing and injection molding of stamp sand and acrylonitrile styrene acrylate waste composite]] | |||

* [[Towards Distributed Recycling with Additive Manufacturing of PET Flake Feedstocks]] | |||

=== Literature Reviews === | |||

[[File:gigarecycle.png|thumb]] | |||

* [[Waste plastic extruder: literature review]] | |||

* [[Life cycle analysis of polymer recycling literature review]] | |||

* [[Solar powered recyclebot literature review]] | |||

* [[Waste plastic extruder: literature review]] | |||

* [[Life cycle analysis of polymer recycling literature review]] | |||

=== | === Externals === | ||

* [http://www.economist.com/news/science-and-technology/21565577-new-manufacturing-technique-could-help-poor-countries-well-rich-ones Economist article on U. of Washington's HDPE boat], [http://web.archive.org/web/20150420060330/http://open3dp.me.washington.edu/2012/07/woof-rocks-the-boat/ Oprn3dp.me] | |||

* [http://www.economist.com/news/science-and-technology/21565577-new-manufacturing-technique-could-help-poor-countries-well-rich-ones Economist article on U. of Washington's HDPE boat], [http://open3dp.me.washington.edu/2012/07/woof-rocks-the-boat/ Oprn3dp.me] | |||

* https://ultimaker.com/en/resources/52444-ocean-plastic-community-project | * https://ultimaker.com/en/resources/52444-ocean-plastic-community-project | ||

* Another possible solution - reusable containers [https://www.cnn.com/interactive/2019/01/business/loop-reusable-packaging-mission-ahead/index.html] | * Another possible solution - reusable containers [https://www.cnn.com/interactive/2019/01/business/loop-reusable-packaging-mission-ahead/index.html] | ||

---- | * Commercial https://dyzedesign.com/pulsar-pellet-extruder/ | ||

* Cruz, F., Lanza, S., Boudaoud, H., Hoppe, S., & Camargo, M. Polymer Recycling and Additive Manufacturing in an Open Source context: Optimization of processes and methods. [http://sffsymposium.engr.utexas.edu/sites/default/files/2015/2015-127-Cruz.pdf] | * --- | ||

* Investigating Material Degradation through the Recycling of PLA in Additively Manufactured Parts | * Cruz, F., Lanza, S., Boudaoud, H., Hoppe, S., & Camargo, M. Polymer Recycling and Additive Manufacturing in an Open Source context: Optimization of processes and methods. [http://web.archive.org/web/20190819114523/http://sffsymposium.engr.utexas.edu:80/sites/default/files/2015/2015-127-Cruz.pdf] | ||

* Mohammed, M.I., Das, A., Gomez-Kervin, E., Wilson, D. and Gibson, I., EcoPrinting: Investigating the use of 100% recycled Acrylonitrile Butadiene Styrene (ABS) for Additive Manufacturing. | * Investigating Material Degradation through the Recycling of PLA in Additively Manufactured Parts | ||

* Mohammed, M.I., Das, A., Gomez-Kervin, E., Wilson, D. and Gibson, I., EcoPrinting: Investigating the use of 100% recycled Acrylonitrile Butadiene Styrene (ABS) for Additive Manufacturing. | |||

* Kariz, M., Sernek, M., Obućina, M. and Kuzman, M.K., 2017. Effect of wood content in FDM filament on properties of 3D printed parts. Materials Today Communications. [https://www.sciencedirect.com/science/article/pii/S2352492817302635] | * Kariz, M., Sernek, M., Obućina, M. and Kuzman, M.K., 2017. Effect of wood content in FDM filament on properties of 3D printed parts. Materials Today Communications. [https://www.sciencedirect.com/science/article/pii/S2352492817302635] | ||

* Kaynak, B., Spoerk, M., Shirole, A., Ziegler, W. and Sapkota, J., 2018. Polypropylene/Cellulose Composites for Material Extrusion Additive Manufacturing. Macromolecular Materials and Engineering, p.1800037. [https://onlinelibrary.wiley.com/doi/pdf/10.1002/mame.201800037] | * Kaynak, B., Spoerk, M., Shirole, A., Ziegler, W. and Sapkota, J., 2018. Polypropylene/Cellulose Composites for Material Extrusion Additive Manufacturing. Macromolecular Materials and Engineering, p.1800037. [https://onlinelibrary.wiley.com/doi/pdf/10.1002/mame.201800037] | ||

* O. Martikka et al., "Mechanical Properties of 3D-Printed Wood-Plastic Composites", Key Engineering Materials, Vol. 777, pp. 499-507, 2018 [https://www.scientific.net/KEM.777.499] | * O. Martikka et al., "Mechanical Properties of 3D-Printed Wood-Plastic Composites", Key Engineering Materials, Vol. 777, pp. 499-507, 2018 [https://www.scientific.net/KEM.777.499] | ||

* Yang, T.C., 2018. Effect of Extrusion Temperature on the Physico-Mechanical Properties of Unidirectional Wood Fiber-Reinforced Polylactic Acid Composite (WFRPC) Components Using Fused Deposition Modeling. Polymers, 10(9), p.976. [http://www.mdpi.com/2073-4360/10/9/976] | * Yang, T.C., 2018. Effect of Extrusion Temperature on the Physico-Mechanical Properties of Unidirectional Wood Fiber-Reinforced Polylactic Acid Composite (WFRPC) Components Using Fused Deposition Modeling. Polymers, 10(9), p.976. [http://www.mdpi.com/2073-4360/10/9/976] | ||

* Romani, A., Rognoli, V., & Levi, M. (2021). Design, Materials, and Extrusion-Based Additive Manufacturing in Circular Economy Contexts: From Waste to New Products. Sustainability, 13(13), 7269. https://www.mdpi.com/2071-1050/13/13/7269/pdf | |||

[[Category:Polymer recycling]] | [[Category:Polymer recycling]] | ||

Latest revision as of 11:23, 19 January 2024

See also[edit source]

RepRapable Recyclebot and the Wild West of Recycling[edit source]

Recycling Technology[edit source]

- Recyclebot

- RepRapable Recyclebot: Open source 3-D printable extruder for converting plastic to 3-D printing filament

- Open Source 3-D Filament Diameter Sensor for Recycling, Winding and Additive Manufacturing Machines

- Improving recyclebot concepts

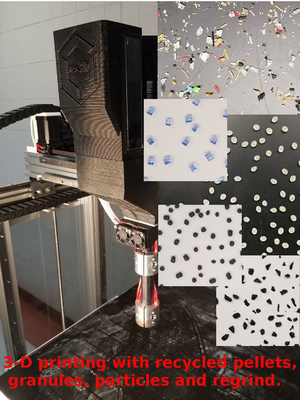

- 3-D Printable Polymer Pelletizer Chopper for Fused Granular Fabrication-Based Additive Manufacturing

- Mechanical Properties of Direct Waste Printing of Polylactic Acid with Universal Pellets Extruder: Comparison to Fused Filament Fabrication on Open-Source Desktop Three-Dimensional Printers

- Fused Particle Fabrication 3-D Printing: Recycled Materials' Optimization and Mechanical Properties

- Multi-material distributed recycling via material extrusion: recycled high density polyethylene and poly (ethylene terephthalate) mixture

- Mechanical Properties and Applications of Recycled Polycarbonate Particle Material Extrusion-Based Additive Manufacturing

- Wood Furniture Waste-Based Recycled 3-D Printing Filament

- Solar powered distributed customized manufacturing

- Mechanical Properties of Ultraviolet-Assisted Paste Extrusion and Postextrusion Ultraviolet-Curing of Three-Dimensional Printed Biocomposites

- Open Source Waste Plastic Granulator

- Open-Source Grinding Machine for Compression Screw Manufacturing

- Sustainability and Feasibility Assessment of Distributed E-Waste Recycling using Additive Manufacturing in a Bi-Continental Context

- Finding Ideal Parameters for Recycled Material Fused Particle Fabrication-Based 3D Printing Using an Open Source Software Implementation of Particle Swarm Optimization

- Waste Plastic Direct Extrusion Hangprinter

- Hangprinter for Large Scale Additive Manufacturing using Fused Particle Fabrication with Recycled Plastic and Continuous Feeding

Distributed Recycling LCA[edit source]

- Tightening the loop on the circular economy: Coupled distributed recycling and manufacturing with recyclebot and RepRap 3-D printing

- Technical pathways for distributed recycling of polymer composites for distributed manufacturing: Windshield wiper blades

- Plastic recycling in additive manufacturing: A systematic literature review and opportunities for the circular economy

- Energy Payback Time of a Solar Photovoltaic Powered Waste Plastic Recyclebot System

- Life cycle analysis of distributed recycling of post-consumer high density polyethylene for 3-D printing filament

- Evaluation of Potential Fair Trade Standards for an Ethical 3-D Printing Filament

- Life cycle analysis of distributed polymer recycling

- Distributed recycling of post-consumer plastic waste in rural areas

- Ethical Filament Foundation

- Green Fab Lab Applications of Large-Area Waste Polymer-based Additive Manufacturing

- Systems Analysis for PET and Olefin Polymers in a Circular Economy

- Potential of distributed recycling from hybrid manufacturing of 3-D printing and injection molding of stamp sand and acrylonitrile styrene acrylate waste composite

- Towards Distributed Recycling with Additive Manufacturing of PET Flake Feedstocks

Literature Reviews[edit source]

- Waste plastic extruder: literature review

- Life cycle analysis of polymer recycling literature review

- Solar powered recyclebot literature review

- Waste plastic extruder: literature review

- Life cycle analysis of polymer recycling literature review

Externals[edit source]

- Economist article on U. of Washington's HDPE boat, Oprn3dp.me

- https://ultimaker.com/en/resources/52444-ocean-plastic-community-project

- Another possible solution - reusable containers [1]

- Commercial https://dyzedesign.com/pulsar-pellet-extruder/

- ---

- Cruz, F., Lanza, S., Boudaoud, H., Hoppe, S., & Camargo, M. Polymer Recycling and Additive Manufacturing in an Open Source context: Optimization of processes and methods. [2]

- Investigating Material Degradation through the Recycling of PLA in Additively Manufactured Parts

- Mohammed, M.I., Das, A., Gomez-Kervin, E., Wilson, D. and Gibson, I., EcoPrinting: Investigating the use of 100% recycled Acrylonitrile Butadiene Styrene (ABS) for Additive Manufacturing.

- Kariz, M., Sernek, M., Obućina, M. and Kuzman, M.K., 2017. Effect of wood content in FDM filament on properties of 3D printed parts. Materials Today Communications. [3]

- Kaynak, B., Spoerk, M., Shirole, A., Ziegler, W. and Sapkota, J., 2018. Polypropylene/Cellulose Composites for Material Extrusion Additive Manufacturing. Macromolecular Materials and Engineering, p.1800037. [4]

- O. Martikka et al., "Mechanical Properties of 3D-Printed Wood-Plastic Composites", Key Engineering Materials, Vol. 777, pp. 499-507, 2018 [5]

- Yang, T.C., 2018. Effect of Extrusion Temperature on the Physico-Mechanical Properties of Unidirectional Wood Fiber-Reinforced Polylactic Acid Composite (WFRPC) Components Using Fused Deposition Modeling. Polymers, 10(9), p.976. [6]

- Romani, A., Rognoli, V., & Levi, M. (2021). Design, Materials, and Extrusion-Based Additive Manufacturing in Circular Economy Contexts: From Waste to New Products. Sustainability, 13(13), 7269. https://www.mdpi.com/2071-1050/13/13/7269/pdf