Pmthomas99 (talk | contribs) |

Sophivorus (talk | contribs) m (Text replacement - "| affiliations = " to "| organizations = ") |

||

| (66 intermediate revisions by 21 users not shown) | |||

| Line 1: | Line 1: | ||

{{Topic notice}} | |||

{{ | |||

[[File:Straw1.jpg|thumb]] | |||

'''Strawbale construction''' offers good [[thermal insulation]], [[thermal mass]], and (depending on the other materials chosen) only natural components, with benefits for [[indoor air quality]]. | |||

Straw bale construction has been around since the early 1900s. Many of the structures built back then are still standing and being used. Some examples of straw bale construction are homes, farm buildings, churches, community centers, etc. | |||

Straw bale construction | |||

Straw is baled material from oats, barley, rice and others. It was traditionally the waste products that farmers did not till under the soil. Instead it was used as bedding or landscape supply due to its durability. It is essentially the dry plant material left over after a plant has been harvested for seed. | |||

== | == Materials Needed == | ||

[[File:Straw house.jpg|thumb|Straw Bale House]] | |||

Straw bales are the key to straw bale construction. Wire mesh should be used to hold these materials together so they are structurally sturdy. Sometimes a wooden frame is used to place your walls so you have a base as to what you are doing. Frames can be used to put windows and doorways into the building. After all is set, fiberglass stucco can be applied to the straw walls. After letting that set, your walls should be sturdy. Don't forget to account for plumbing and wiring as well. | |||

After your house is built, feel free to furnish it with whatever you want. Wooden floors can be put in as well as basements but be sure that your foundation is strong enough to hold. | |||

To learn about one man's construction try this article: [https://web.archive.org/web/20101231120535/http://www.thefarm.org/charities/i4at/lib2/strwbale.htm] | |||

A Sourcebook for Green and Sustainable Building: http://www.greenbuilder.com/sourcebook/strawbale.html#Define | == Skills and Knowledge Necessary == | ||

[[File:Kivagreenhouse1 (67).jpg|thumb]] | |||

Straw bale construction essentially the same as building construction for a home. All you need to do is make sure your walls are sealed properly so that no moisture or oxygen gets in. Any contractor can be hired for this or you can do it yourself. One must be capable of reading blueprints and being able to run heavy machinery. Also, you must be able to understand the blueprints so that if a problem arises, you can read back and figure out what went wrong. | |||

Straw bale building typically consists of stacking rows of bales (often in running-bond) on a raised footing or foundation, with a moisture barrier or capillary break between the bales and their supporting platform. Bale walls can be tied together with pins of bamboo, rebar, or wood (internal to the bales or on their faces), or with surface wire meshes, and then stuccoed or plastered, either with a cement-based mix, lime-based formulation, or earth/clay render. The bales may actually provide the structural support for the building ("load-bearing" or "Nebraska-style" technique), as was the case in the original examples from the late 19th century. | |||

Alternatively, bale buildings can have a structural frame of other materials, usually lumber or timber-frame, with bales simply serving as insulation and plaster substrate, ("infill" or "non-loadbearing" technique), which is most often required in northern regions and/or in wet climates. In northern regions, the potential snow-loading can exceed the strength of the bale walls. In wet climates, the imperative for applying a vapor-permeable finish precludes the use of cement-based stucco commonly used on load-bearing bale walls. Additionally, the inclusion of a skeletal framework of wood or metal allows the erection of a roof prior to raising the bales, which can protect the bale wall during construction, when it is the most vulnerable to water damage in all but the most dependably arid climates. A combination of framing and load-bearing techniques may also be employed, referred to as "hybrid" straw bale construction. | |||

== Open Source Strawbale designs == | |||

An open-source straw bale housing prototype has been developed by the [http://openarchitecturenetwork.org/node/641 Open Architecture Network] | |||

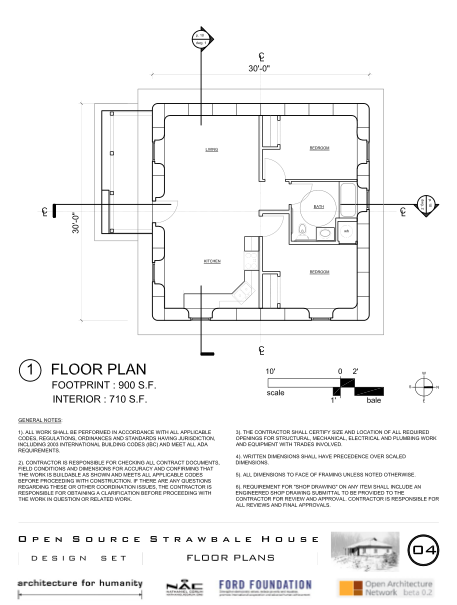

[[File:Floorplan.png]] | |||

This simple Open Source home design grew out of a desire to share a easy-to-construct straw bale prototype for humanitarian applications. The barrier-free floor plan, comprised of a concentrated wet core within an insulating straw bale envelope, allows for an efficient layout within a small footprint. This system can scale up or down, orient to solar and wind patterns for passive heating and cooling, and be partitioned flexibly in order to adapt to changing inhabitant needs. | |||

This Open Source design also takes advantage of solar gain. Winter sunlight enters south-facing windows and charges a thermal mass in the floor. A radiant floor system provides supplementary heating. Attic insulation is post-consumer cellulose (i.e., newspaper). A frost-protected shallow foundation obviates the need of excavation below frost line and is therefore less invasive than conventional cold-weather foundations. | |||

[[Media:Open-Source Straw-Bale House OAN (1).pdf|.PDF file for viewing]] | |||

[https://web.archive.org/web/20170819194948/http://opensourceecology.org:80/w/images/a/a0/Open_Source_Strawbale_House.dwg.DWG Files to download and edit] | |||

== Estimated Costs == | |||

Cost all depends on the design of the building. Location is a main key to this as well. Questions that should be asked should be about regulations, building codes, structural sustainability, etc. Straw bale construction is much cheaper though in terms of wood foundations. This can be one of the most economical wall systems. Houses have been constructed for as low as $10.00 per square foot (floor area) to high end homes at $100.00 per square foot. | |||

== Related projects == | |||

{{Gallery | |||

| instance-of = Straw bale construction | |||

}} | |||

== See also == | |||

* [[Papercrete vs. StrawBale]] | |||

== External links == | |||

* [https://permies.com/f/73/straw-bale-house Straw bale house forums] at [https://permies.com Permies.com] | |||

* [[Wikipedia:Straw bale construction]] | |||

* A [https://en.wikibooks.org/wiki/Straw_Bale_Construction Wikibook on Straw bale construction] | |||

* http://www.strawbale.com/ | |||

* [http://www.dcat.net/resources/California_Straw_Bale_Code.pdf California strawbale code] | |||

* A Sourcebook for Green and Sustainable Building: http://www.greenbuilder.com/sourcebook/strawbale.html#Define | |||

{{Page data | |||

| keywords = strawbale, construction, Thermal insulation, Alternative building, thermal mass, indoor air quality, Wire mesh, wood, fiberglass stucco, energy efficiency, How tos, Construction and materials, construction, materials, Strawbale | |||

| sdg = SDG11 Sustainable cities and communities | |||

| authors = User:Pmthomas99 | |||

| published = 2007 | |||

| organizations = Clarion University | |||

| part-of = PH261 | |||

}} | |||

[[Category:Strawbale]] | |||

[[Category:Construction]] | |||

[[Category:Alternative building]] | |||

[[Category:Wood]] | |||

[[Category:Energy efficiency]] | |||

[[Category:How tos]] | |||

[[Category:Construction and materials]] | |||

[[Category:Materials]] | |||

Latest revision as of 12:37, 28 February 2024

Strawbale construction offers good thermal insulation, thermal mass, and (depending on the other materials chosen) only natural components, with benefits for indoor air quality.

Straw bale construction has been around since the early 1900s. Many of the structures built back then are still standing and being used. Some examples of straw bale construction are homes, farm buildings, churches, community centers, etc.

Straw is baled material from oats, barley, rice and others. It was traditionally the waste products that farmers did not till under the soil. Instead it was used as bedding or landscape supply due to its durability. It is essentially the dry plant material left over after a plant has been harvested for seed.

Materials Needed[edit | edit source]

Straw bales are the key to straw bale construction. Wire mesh should be used to hold these materials together so they are structurally sturdy. Sometimes a wooden frame is used to place your walls so you have a base as to what you are doing. Frames can be used to put windows and doorways into the building. After all is set, fiberglass stucco can be applied to the straw walls. After letting that set, your walls should be sturdy. Don't forget to account for plumbing and wiring as well. After your house is built, feel free to furnish it with whatever you want. Wooden floors can be put in as well as basements but be sure that your foundation is strong enough to hold. To learn about one man's construction try this article: [1]

Skills and Knowledge Necessary[edit | edit source]

Straw bale construction essentially the same as building construction for a home. All you need to do is make sure your walls are sealed properly so that no moisture or oxygen gets in. Any contractor can be hired for this or you can do it yourself. One must be capable of reading blueprints and being able to run heavy machinery. Also, you must be able to understand the blueprints so that if a problem arises, you can read back and figure out what went wrong.

Straw bale building typically consists of stacking rows of bales (often in running-bond) on a raised footing or foundation, with a moisture barrier or capillary break between the bales and their supporting platform. Bale walls can be tied together with pins of bamboo, rebar, or wood (internal to the bales or on their faces), or with surface wire meshes, and then stuccoed or plastered, either with a cement-based mix, lime-based formulation, or earth/clay render. The bales may actually provide the structural support for the building ("load-bearing" or "Nebraska-style" technique), as was the case in the original examples from the late 19th century.

Alternatively, bale buildings can have a structural frame of other materials, usually lumber or timber-frame, with bales simply serving as insulation and plaster substrate, ("infill" or "non-loadbearing" technique), which is most often required in northern regions and/or in wet climates. In northern regions, the potential snow-loading can exceed the strength of the bale walls. In wet climates, the imperative for applying a vapor-permeable finish precludes the use of cement-based stucco commonly used on load-bearing bale walls. Additionally, the inclusion of a skeletal framework of wood or metal allows the erection of a roof prior to raising the bales, which can protect the bale wall during construction, when it is the most vulnerable to water damage in all but the most dependably arid climates. A combination of framing and load-bearing techniques may also be employed, referred to as "hybrid" straw bale construction.

Open Source Strawbale designs[edit | edit source]

An open-source straw bale housing prototype has been developed by the Open Architecture Network

This simple Open Source home design grew out of a desire to share a easy-to-construct straw bale prototype for humanitarian applications. The barrier-free floor plan, comprised of a concentrated wet core within an insulating straw bale envelope, allows for an efficient layout within a small footprint. This system can scale up or down, orient to solar and wind patterns for passive heating and cooling, and be partitioned flexibly in order to adapt to changing inhabitant needs.

This Open Source design also takes advantage of solar gain. Winter sunlight enters south-facing windows and charges a thermal mass in the floor. A radiant floor system provides supplementary heating. Attic insulation is post-consumer cellulose (i.e., newspaper). A frost-protected shallow foundation obviates the need of excavation below frost line and is therefore less invasive than conventional cold-weather foundations.

Estimated Costs[edit | edit source]

Cost all depends on the design of the building. Location is a main key to this as well. Questions that should be asked should be about regulations, building codes, structural sustainability, etc. Straw bale construction is much cheaper though in terms of wood foundations. This can be one of the most economical wall systems. Houses have been constructed for as low as $10.00 per square foot (floor area) to high end homes at $100.00 per square foot.

Related projects[edit | edit source]

See also[edit | edit source]

External links[edit | edit source]

- Straw bale house forums at Permies.com

- Wikipedia:Straw bale construction

- A Wikibook on Straw bale construction

- http://www.strawbale.com/

- California strawbale code

- A Sourcebook for Green and Sustainable Building: http://www.greenbuilder.com/sourcebook/strawbale.html#Define